Leakage-proof sandwich thermal insulation concrete outer wall board based on horizontal joints and vertical joints

A technology of thermal insulation concrete and vertical joints, which can be used in building thermal insulation materials, walls, building components, etc., and can solve problems such as water seepage and easy cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, further illustrate the present invention.

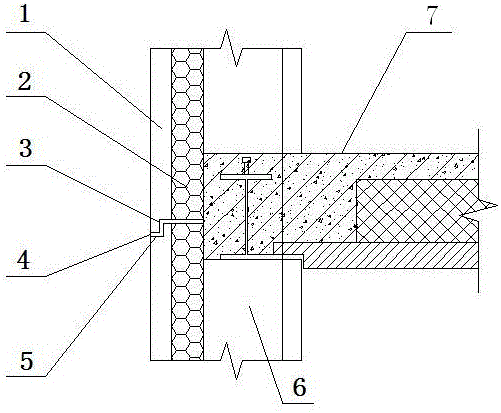

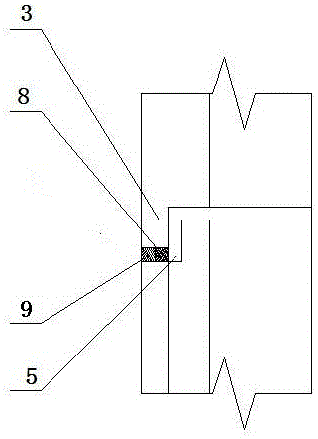

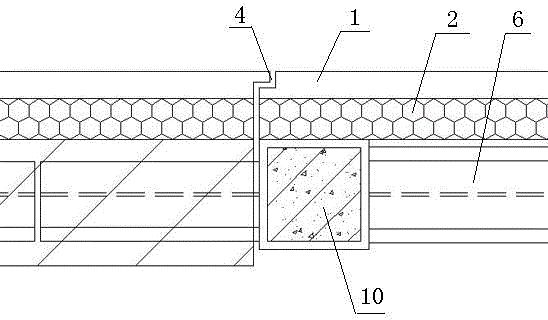

[0017] see figure 1 , figure 2 , a sandwich insulation concrete exterior wall panel based on horizontal joints and vertical joints to prevent leakage. From the outside to the inside, it consists of a reinforced concrete outer leaf 1 (outer layer) with a thickness of 50mm and an extruded polystyrene board 2 with a thickness of 75mm. 1, a reinforced concrete inner leaf 7 with a thickness of 200mm, and a reinforced concrete outer leaf 1 (inner layer) with a thickness of 30mm. The reinforced concrete outer leaf 1 of the outer layer is provided with grooves around it, and between two adjacent grooves There is a seam 4 with a width of 10mm, and the inside of the seam 4 is filled with a rubber strip 8 with a thickness of 10mm. The exterior of the seam 4 is sealed with a waterproof sealant 9 compatible with concrete, and the thickness of the waterproof sealant 9 is 10mm.

[0018] The above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com