Underwater anti-blocking and resistance-reducing elbow structure

A pipe bending and anti-blocking technology, which is applied in the direction of elbows, siphons, pipe components, etc., can solve the problems of inner wall wear of pipe fittings, large water flow resistance of ordinary pipe fittings, and pipe fitting blockage, so as to enhance the swirling effect, avoid solid particle deposition, The effect of preventing clogging of elbows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

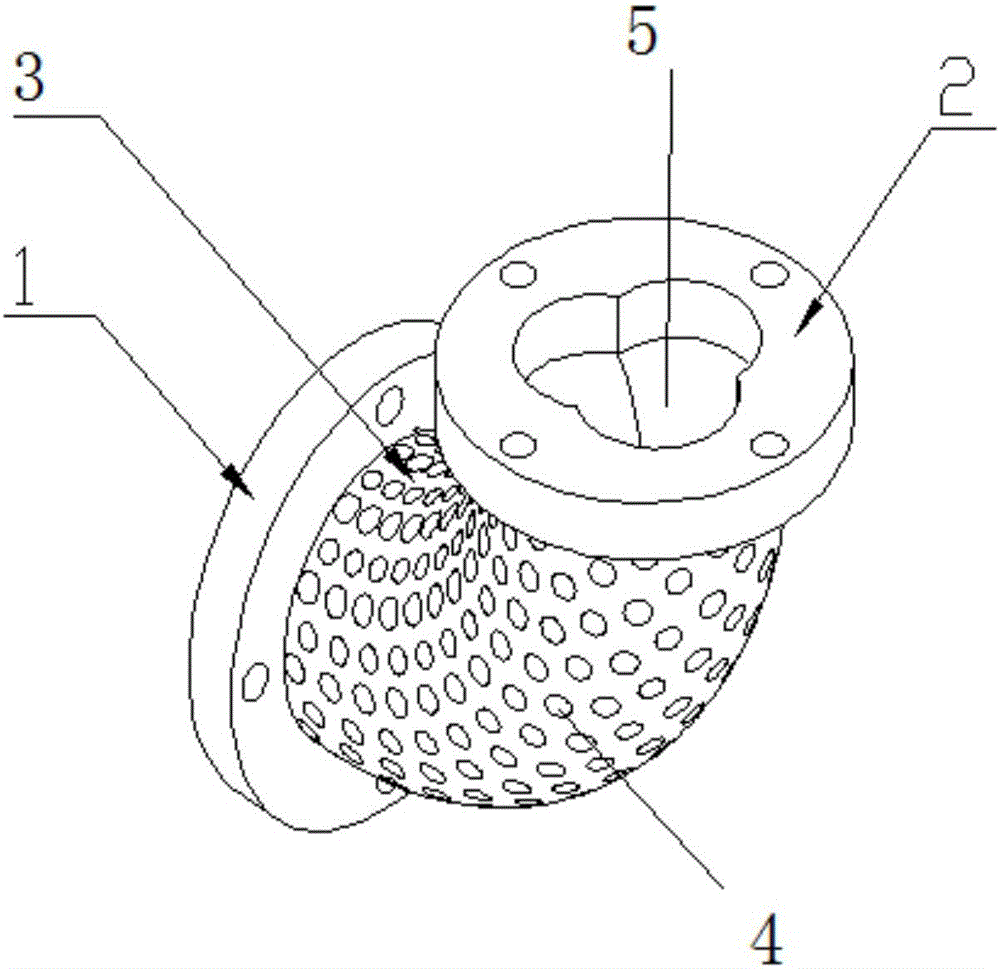

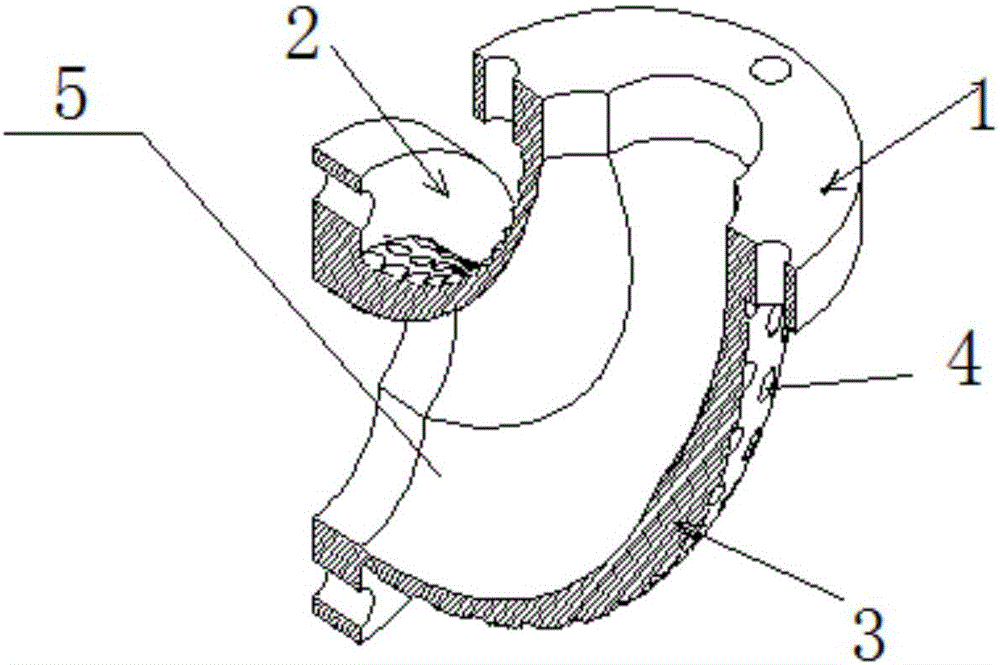

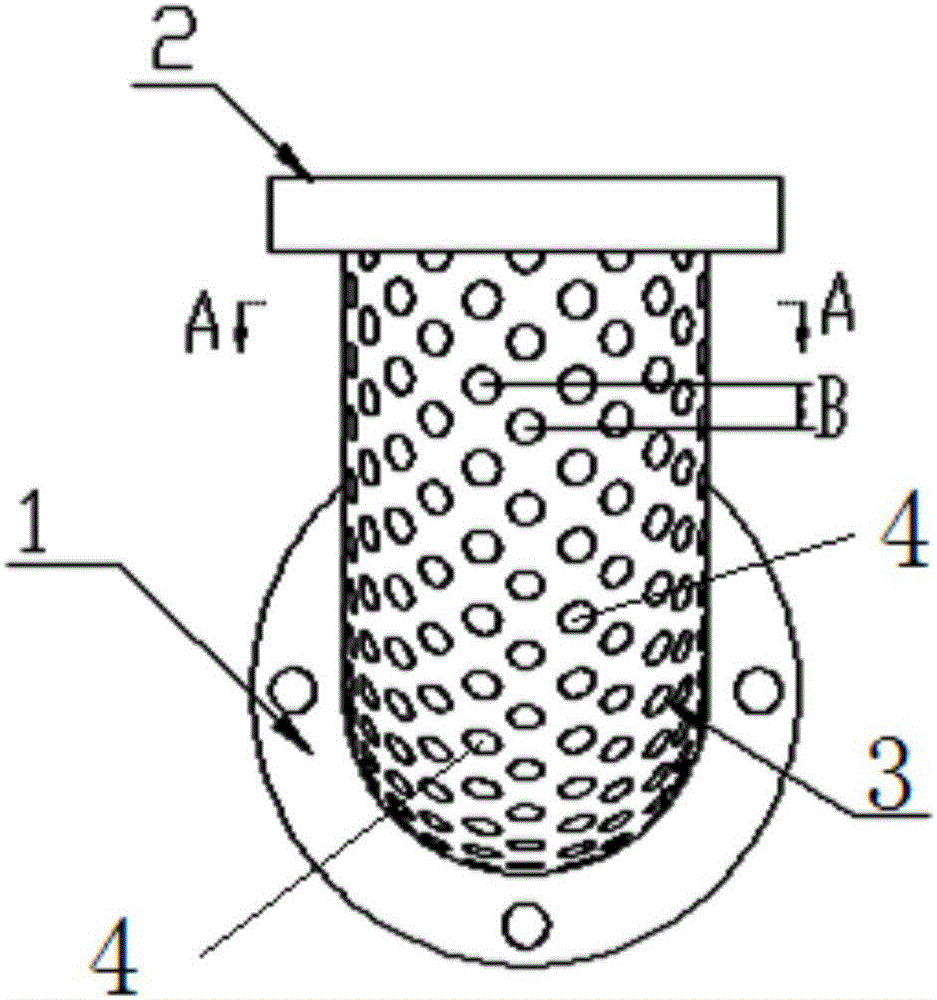

[0028] As shown in the drawings, an underwater elbow structure for anti-clogging and drag reduction includes an elbow 3 , an inlet flange 1 and an outlet flange 2 arranged at both ends of the elbow 3 .

[0029] A plurality of spiral grooves 5 are arranged inside the flow channel of the elbow 3 along its length direction, and a plurality of pits 4 are formed on the outer surfaces of the main pipe section 3 and the transition section 2 respectively. The spiral groove 5 is used to prevent particles from clogging the elbow 3 . Dimples 4 are used to reduce hydraulic resistance.

[0030] In this embodiment, the angle of the elbow 3 is 90 degrees, the outer diameter of the elbow 3 is 110 millimeters, the length from the center of the elbow 3 to the end face is 120 millimeters, and the hydraulic diameter of the inner spiral groove 5 of the elbow 3 is 80 millimeters. The outer diameter of the flange 1 and the outlet flange 2 is 229 mm, the inner diameter of the flange is 102 mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com