Honeycomb type heater

A technology of honeycomb heaters and heaters, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as reduced service life, easy scaling of inner tanks, and insufficient heat transfer, and achieve the goal of using Long service life, no temperature leakage, and smooth hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

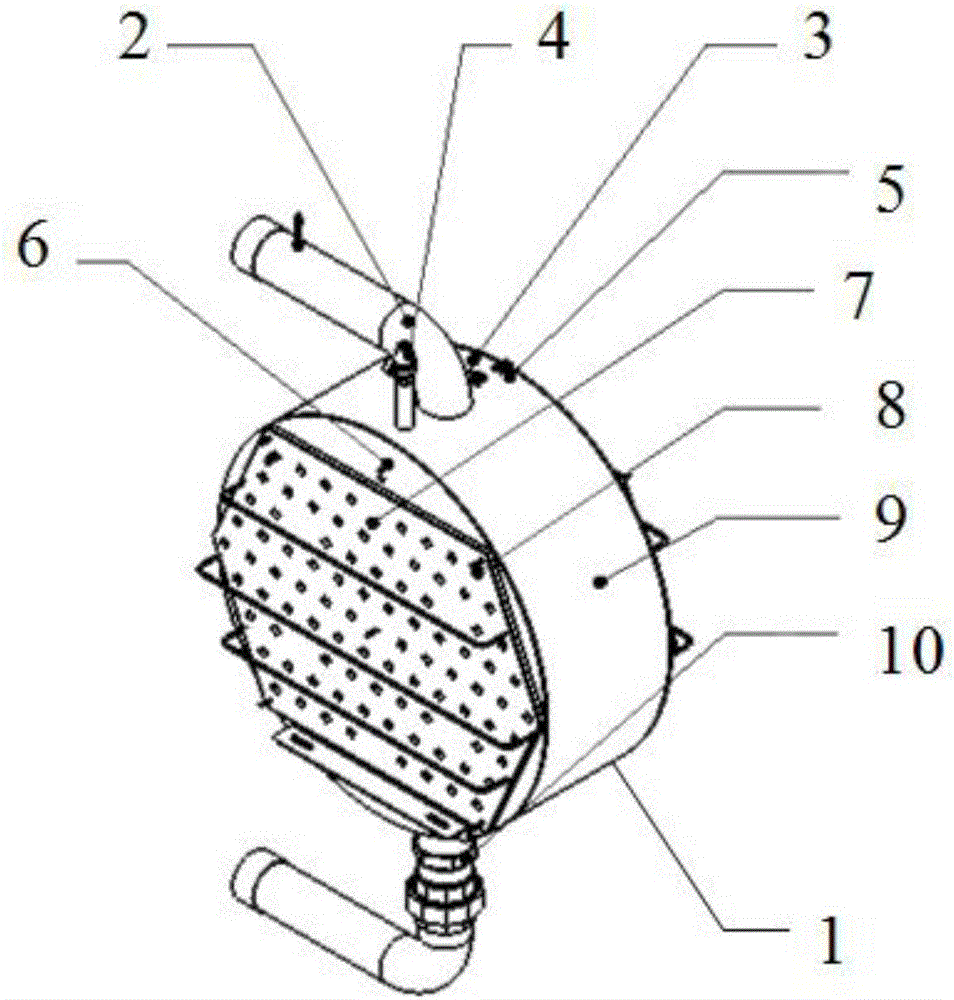

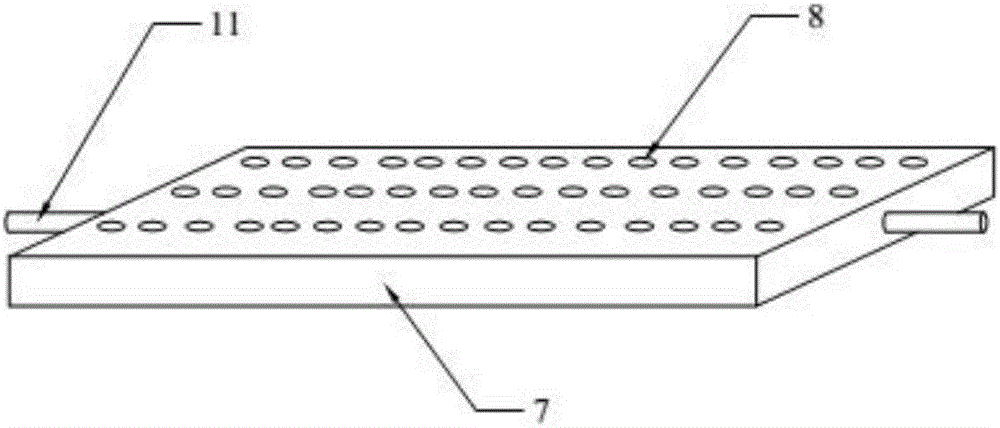

[0016] Example 1, such as figure 1 , 2 , shows: a honeycomb heater, its structure includes: heater body 1, water inlet pipe 2, over-temperature switch 3, safety valve 4, over-temperature sensor 5, temperature sensor 6, honeycomb panel 7, crystal radiation heating element 8. Aluminum silicate thermal insulation cotton 9, outlet pipe 10, connecting pipe 11; the heater body 1 is a hollow ring structure, and a water inlet pipe 2 is connected directly above the outer rotating surface of the heater body 1. A circular hole, a circular hole communicating with the water outlet pipe 10 is provided directly below the outer turning surface of the heater body 1, and the overtemperature switch 3 is arranged on the rear side of the heater body 1 provided with the water inlet pipe 2, The safety valve 4 is arranged on the front side of the heater body 1 provided with the water inlet pipe 2, the overtemperature sensor 5 is arranged on the adjacent side of the overtemperature switch 3, and the ...

Embodiment 2

[0018] Example 2, such as figure 1 , 2 , shows: a honeycomb heater, its structure includes: heater body 1, water inlet pipe 2, over-temperature switch 3, safety valve 4, over-temperature sensor 5, temperature sensor 6, honeycomb panel 7, crystal radiation heating element 8. Aluminum silicate thermal insulation cotton 9, outlet pipe 10, connecting pipe 11; the heater body 1 is a hollow ring structure, and a water inlet pipe 2 is connected directly above the outer rotating surface of the heater body 1. A circular hole, a circular hole communicating with the water outlet pipe 10 is provided directly below the outer turning surface of the heater body 1, and the overtemperature switch 3 is arranged on the rear side of the heater body 1 provided with the water inlet pipe 2, The safety valve 4 is arranged on the front side of the heater body 1 provided with the water inlet pipe 2, the overtemperature sensor 5 is arranged on the adjacent side of the overtemperature switch 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com