Steel structure surface fireproof spray paint

A technology of steel structure and parts by weight, used in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve problems such as late start of research, gaps in physical and chemical properties and weather resistance, environmental and construction personnel hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

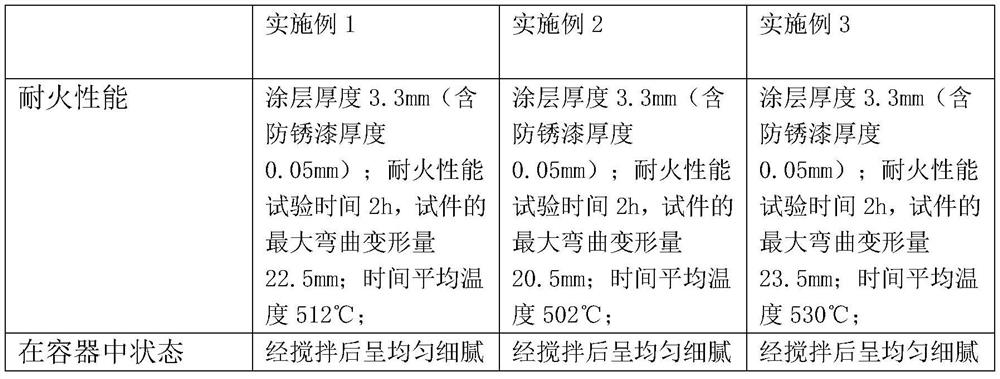

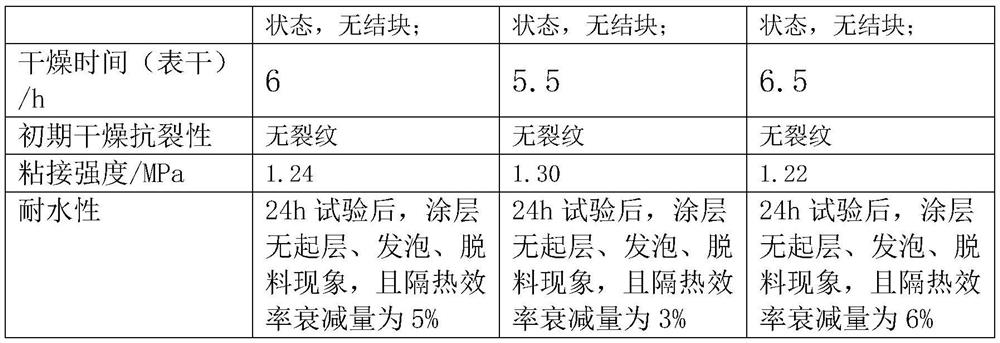

Examples

Embodiment 1

[0015] A kind of fireproof spray paint on the surface of steel structure is made of the following raw materials in parts by weight:

[0016] 26 parts of acrylic emulsion, 10 parts of vinyl acetate-ethylene copolymer emulsion, 6 parts of expanded graphite, 8 parts of low-density polyethylene, 2 parts of ammonium polyphosphate, 4 parts of carbon fiber, 5 parts of silicon nitride fiber, 21 parts of water, hydroxyl acrylic resin 11 parts, 12 parts of polyurethane resin, 1 part of potassium dihydrogen phosphate, 6 parts of pentaerythritol, 6 parts of melamine phosphate, 11 parts of white carbon black, 6 parts of sodium silicate, 1 part of dispersant, 12 parts of sec-butyl acetate, Thiocarbamate 2 parts.

[0017] Mix expanded graphite, low-density polyethylene, ammonium polyphosphate and water in a stirred tank and put them into a ball mill to grind for 1 hour. The speed of the ball mill is 1000r / min;

[0018] Then slowly add acrylic acid emulsion and vinyl acetate-ethylene copolym...

Embodiment 2

[0020] 33 parts of acrylic emulsion, 12 parts of vinyl acetate-ethylene copolymer emulsion, 8 parts of expanded graphite, 9 parts of low-density polyethylene, 6 parts of ammonium polyphosphate, 6 parts of carbon fiber, 7 parts of silicon nitride fiber, 25 parts of water, hydroxyl acrylic resin 11 parts, 14 parts of polyurethane resin, 1 part of potassium dihydrogen phosphate, 7 parts of pentaerythritol, 7.5 parts of melamine phosphate, 11 parts of white carbon black, 7 parts of sodium silicate, 1 part of dispersant, 13 parts of sec-butyl acetate, two Thiocarbamate 1.5 parts.

[0021] Mix expanded graphite, low-density polyethylene, ammonium polyphosphate and water in a stirred tank and put them into a ball mill to grind for 1 hour. The speed of the ball mill is 1000r / min;

[0022] Then slowly add acrylic acid emulsion and vinyl acetate-ethylene copolymer emulsion into the ball mill, continue to grind for 2 hours, filter to obtain a slurry with a fineness of 80-90 mesh, put the...

Embodiment 3

[0024] A kind of fireproof spray paint on the surface of steel structure is made of the following raw materials in parts by weight:

[0025] 40 parts of acrylic emulsion, 13 parts of vinyl acetate-ethylene copolymer emulsion, 10 parts of expanded graphite, 10 parts of low density polyethylene, 10 parts of ammonium polyphosphate, 8 parts of carbon fiber, 9 parts of silicon nitride fiber, 30 parts of water, hydroxyl acrylic resin 12 parts, 15 parts of polyurethane resin, 2 parts of potassium dihydrogen phosphate, 8 parts of pentaerythritol, 9 parts of melamine phosphate, 12 parts of white carbon black, 8 parts of sodium silicate, 2 parts of dispersant, 14 parts of sec-butyl acetate, Thiocarbamate 3 parts.

[0026] Mix expanded graphite, low-density polyethylene, ammonium polyphosphate and water in a stirred tank and put them into a ball mill to grind for 2 hours. The speed of the ball mill is 1200r / min;

[0027] Then slowly add acrylic acid emulsion and vinyl acetate-ethylene c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com