Contour scanning measurement device and method for large-aperture high-curvature optical element based on confocal microscopy

A technology of confocal microscopy and optical components, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult detection, slow measurement speed, large error, etc., and achieve the effect of cost reduction and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

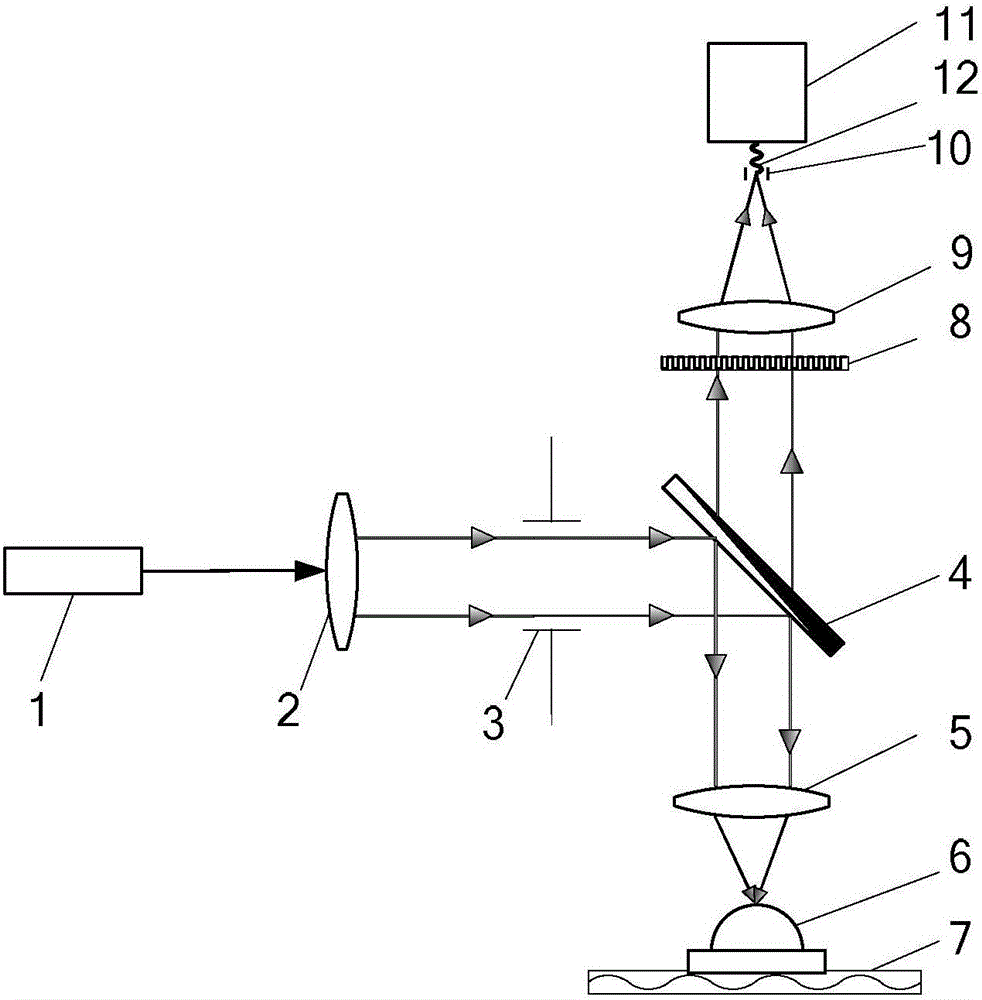

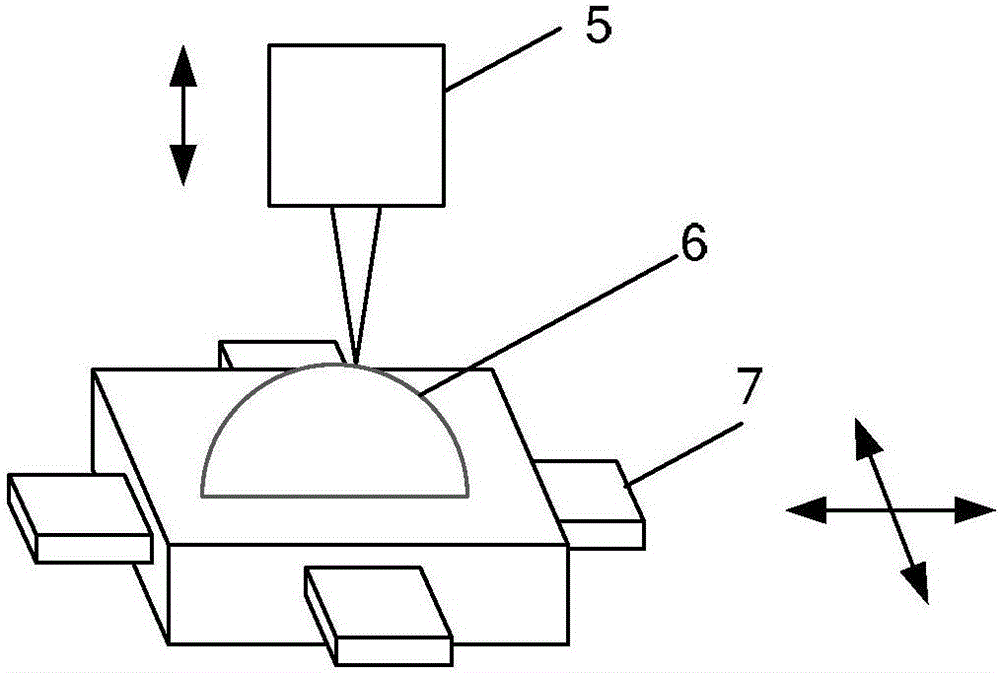

[0026] Specific implementation mode one: combine figure 1 Specifically explain this embodiment, the profile scanning measurement device based on confocal microscopy technology of large aperture and high curvature optical elements described in this embodiment includes a confocal microscopy system and a two-dimensional air-floating motion platform 7;

[0027] The confocal microscope system includes an illumination system and a detection system;

[0028] The illumination system comprises a laser 1, a collimating mirror 2, an aperture 3, a dichroic mirror 4 and an objective lens 5;

[0029] The laser light emitted by the laser 1 passes through the collimating mirror 2 to form parallel light, and the parallel light enters the dichroic mirror 4 through the aperture 3, and the dichroic mirror 4 reflects the laser light to the The objective lens 5 focuses the laser light onto the sample to be tested 6, and the sample to be tested 6 is placed on the two-dimensional air-floating motion...

specific Embodiment approach 2

[0035] Specific embodiment 2: This embodiment is a further description of the profile scanning measurement device based on confocal microscopy technology for large-aperture and high-curvature optical elements described in specific embodiment 1. In this embodiment, the laser light emitted by the laser 1 The wavelength is 532nm.

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment is a further description of the profile scanning measurement device based on the confocal microscopy technology of the large-aperture high-curvature optical element described in the specific embodiment one or two. In this embodiment, the object lens 5 transmits The laser power is greater than 0mW and less than 50mW.

[0037] The laser power incident on the sample 7 to be tested is less than 50 mW, which ensures that the surface of the sample 7 to be tested can excite fluorescence without damaging the sample to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com