Surface acoustic wave double-resonator integrated torque sensor based on Rayleigh wave mode

A torque sensor and surface acoustic wave technology, applied in the field of shafting torque testing, can solve the problems of undisclosed sensitive unit structure and specific technical parameters, so as to avoid stability and reliability problems, improve torque sensitivity, and achieve torque accuracy measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention utilizes the Rayleigh wave mode resonator in the surface acoustic wave (SAW), and realizes the device for accurate torque measurement by optimizing the selection of the substrate cut shape and the integrated structure of the double resonator.

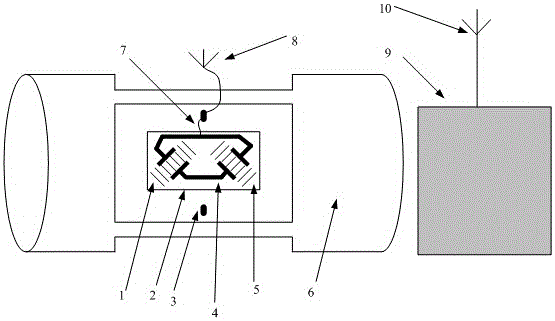

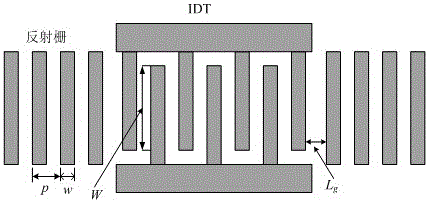

[0016] Such as figure 1 The structure schematic diagram of the surface acoustic wave dual resonator integrated torque sensor based on the Rayleigh wave mode is shown, including the rotating shaft elastic body 6 and the reader 9, the rectangular quartz substrate 2 is fixed on the surface of the rotating shaft elastic body 6, and the pad 3 is insulated The layer transition is pasted on the rotating shaft elastic body 6 for the connection of the antenna 8 during on-site installation. On the quartz substrate 2, two surface acoustic wave resonators 1 and 5 placed orthogonally are made at one time by the IC process, and the directions of resonance are respectively symmetrical to the quartz crystal axis X at ±45°, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com