Terahertz wave polarizing beam splitter with silicon hole array structure

A polarization beam splitter and array structure technology, applied in the direction of instruments, light guides, optics, etc., can solve the problems of high cost, complex structure, and low polarization beam splitting efficiency, and achieve small size, small volume, and high polarization beam splitting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

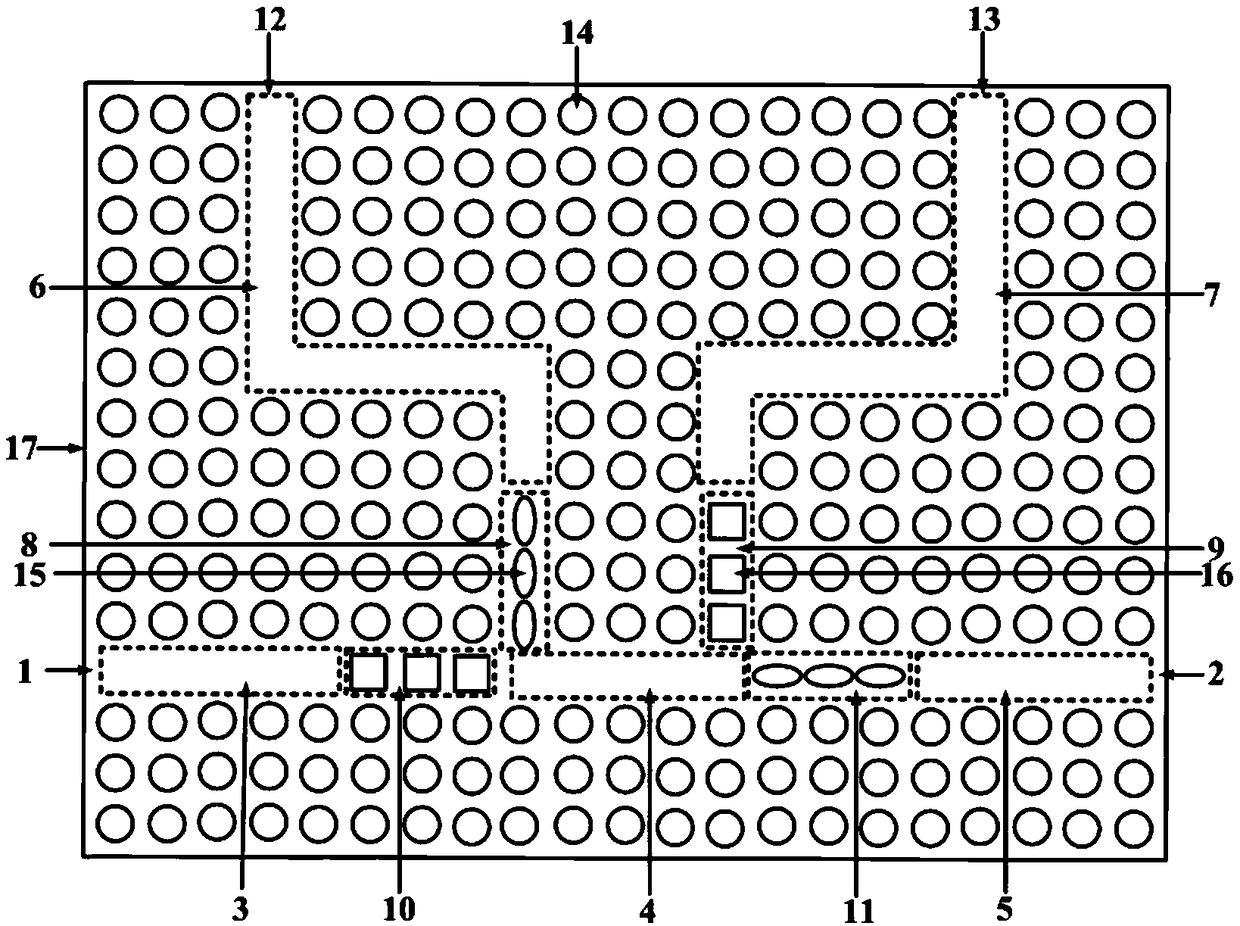

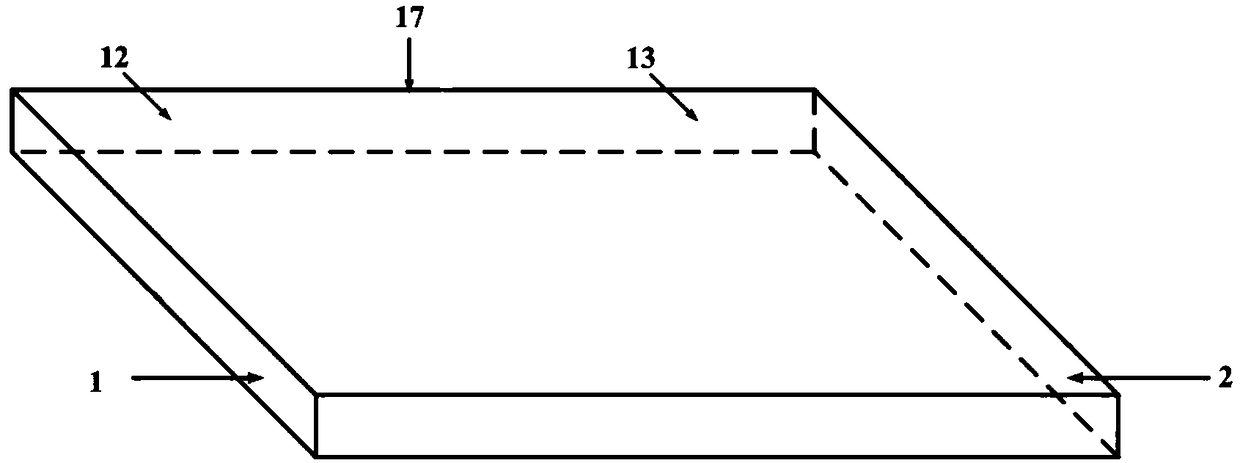

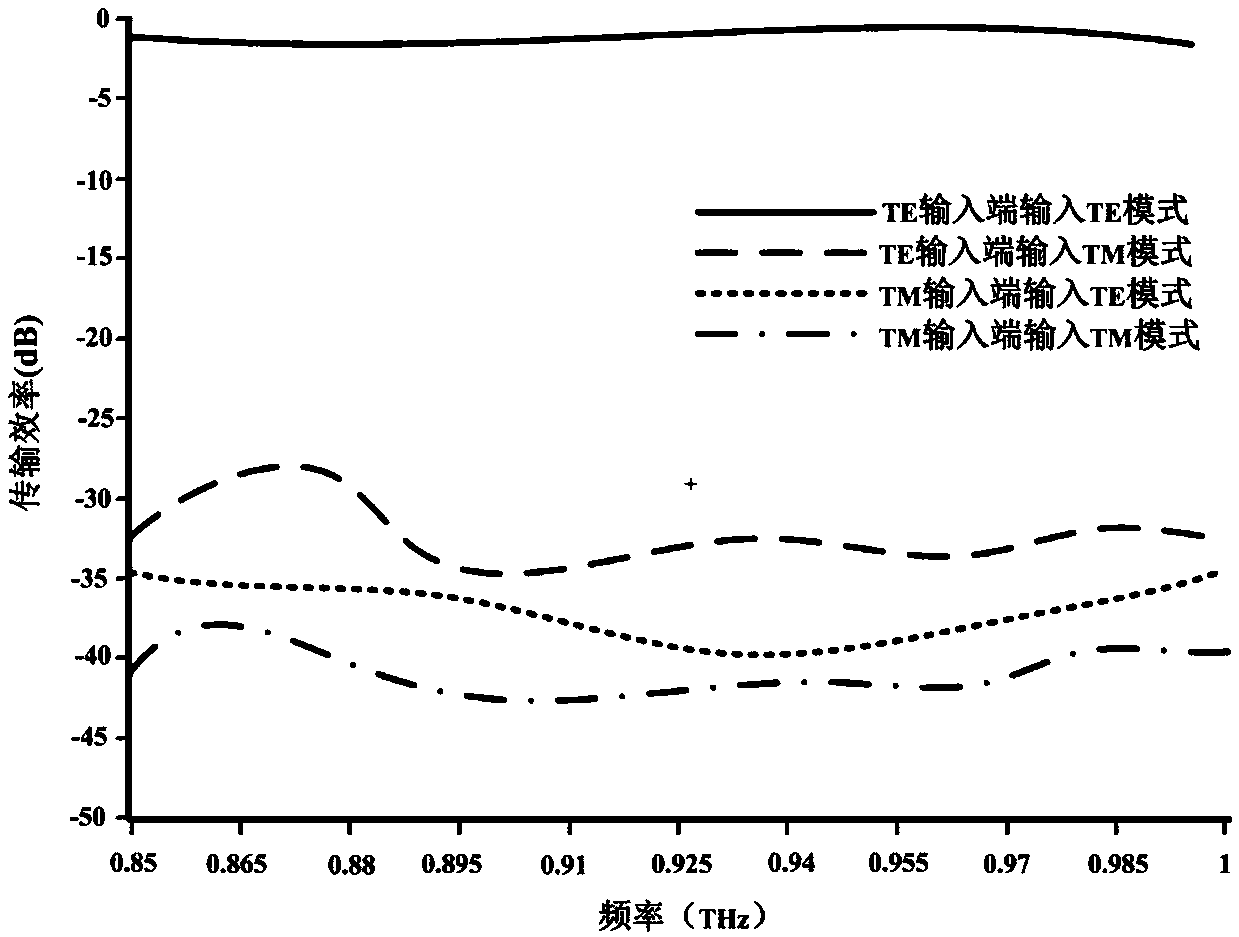

[0016] In this embodiment, the structure of the terahertz wave polarizing beam splitter is also as described above ( figure 1 and 2 ), the specific structure will not be repeated here. The specific structural parameters of the terahertz wave polarizing beam splitter are: the material of the hollow plate is silicon, and the refractive index is 3.45. The radius of the circular air holes is 39-41 μm, and the distance between the centers of adjacent circular air holes is 119-121 μm. The long axis of the elliptical air hole is 99-102 μm, the short axis is 39-41 μm, and the distance between the centers of adjacent elliptical air holes is 119-121 μm. The side length of the square air holes is 83-85 μm, and the distance between the centers of adjacent square air holes is 119-121 μm. image 3 It is the output power curve of the TE signal output terminal in the range of 0.85THz~1THz. It can be seen that only the TE mode terahertz wave input from the TE signal input terminal can be ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com