Memory unit device and manufacture method thereof

A technology of memory cells and manufacturing methods, which is applied in the manufacture of memory cell devices and the field of memory cell devices, and can solve problems such as loss, large voltage difference, and easy drain interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

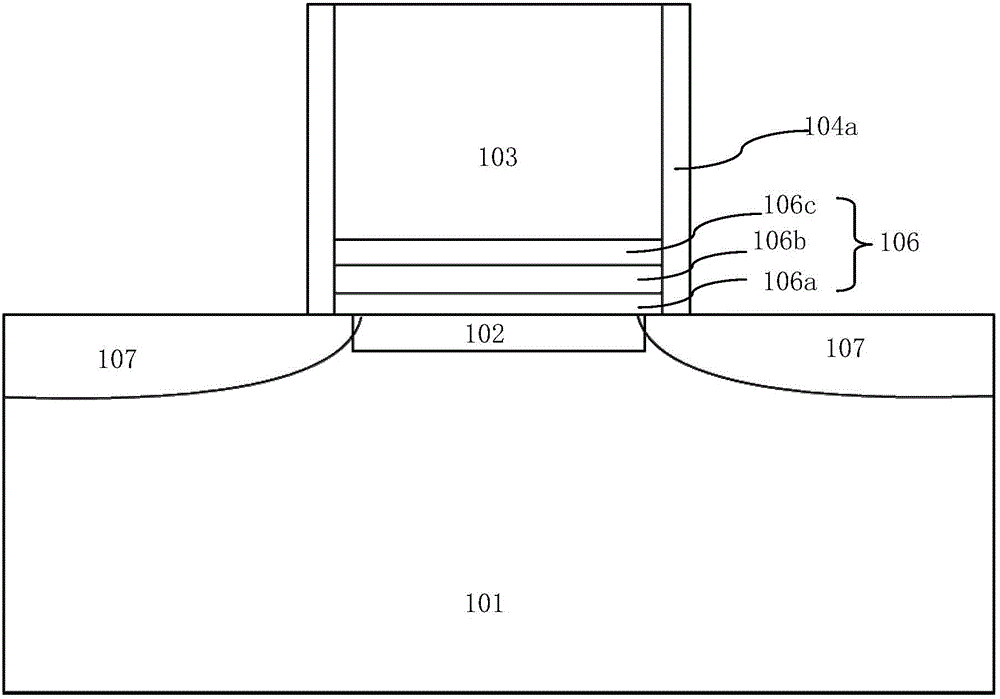

[0066] The polysilicon gate of the existing memory cell device overlaps with the source and drain regions on both sides, such as Figure 2A to Figure 2D Shown is a schematic structural view of each step in the manufacturing method of the existing memory unit device; the manufacturing method of the existing memory unit device includes the following steps:

[0067] Step 1. Firstly, conventional well implantation is performed to form a well region on the surface of a semiconductor substrate such as a silicon substrate 101 . Such as Figure 2A As shown, a channel implant (Channel Implant) or a depletion implant (Depletion Implant) is then performed to form a channel region 102 on the surface of the semiconductor substrate.

[0068] Step two, such as Figure 2B As shown, a gate structure formed by overlapping the gate ONO layer 106 and the polysilicon gate 103 is sequentially formed on the surface of the semiconductor substrate 101 . The gate structure needs to be formed by depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com