Special cooking forming box for konjak tofu

The technology of konjac tofu and forming box is applied in the fields of application, food forming, food science, etc. It can solve the problems of uneven elasticity, low quality and rough texture of konjac tofu, so as to facilitate rinsing to remove alkaline odor and reduce the amount of water , The effect of delicate and consistent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

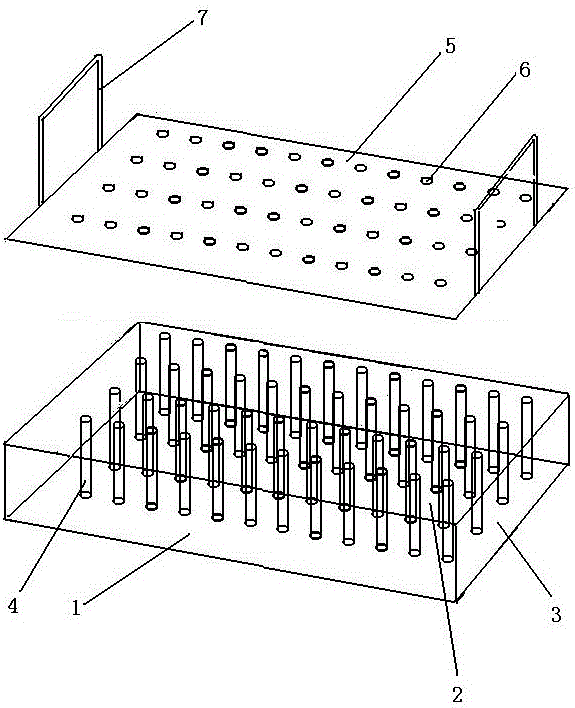

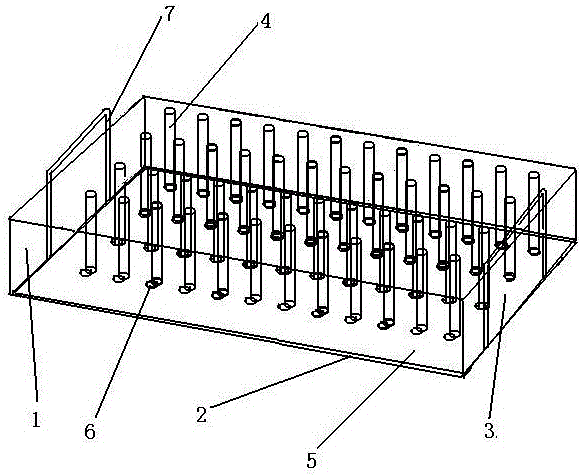

[0017] As shown in the figure, a special cooking and forming box for konjac tofu is produced, including a forming box 1, the forming box includes a forming box bottom 2 and a forming box wall 3, and several dense tube hole columns are vertically arranged on the forming box bottom 2 4, and make the pipe hole cavity in the pipe hole column 4 directly penetrate the forming box bottom 2 and lead to the outside of the forming box bottom 2; in addition, a movable bottom plate 5 is provided on the forming box bottom 2, and a supporting hole is set on the movable bottom plate 5 A plurality of dense round holes for the pipe hole column 4 to pass through, the movable bottom plate 5 is sleeved on the pipe hole column 4, and a handle 7 is also provided on the edge of the movable bottom plate 5 .

Embodiment 2

[0019] On the basis of embodiment 1, the height of the tube hole column 4 is made flush with the height of the forming box wall 3; generally the thickness of the forming konjac tofu block is preset as about 15cm, and the forming box wall 3 and the tube hole are formed here The height of column 4 is all made as 30cm.

[0020] During use, align the round holes 6 on the movable bottom plate 5 with the tube hole column 4 on the bottom of the forming box 2, and pass the movable bottom plate 5 through the tube hole column 4, so that the movable bottom plate 5 is close to the bottom of the forming box 2; The slurry is directly poured into the cooking and forming box, and then the cooking and forming box is put into the cooking pot for cooking, so that the boiling water in the cooking pot can reach the tube hole column 4, so that the konjac tofu pieces in the cooking and forming box are evenly heated and matured. After the konjac tofu is formed and matured, lift the handle 7 on the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com