Waxy wheat flour milling technological method

A process method, the technology of waxy wheat, applied in the field of wheat flour milling process, can solve the problems of backward production process, high power consumption, starch particle and protein damage, etc., so as to improve flour yield, reduce energy consumption and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

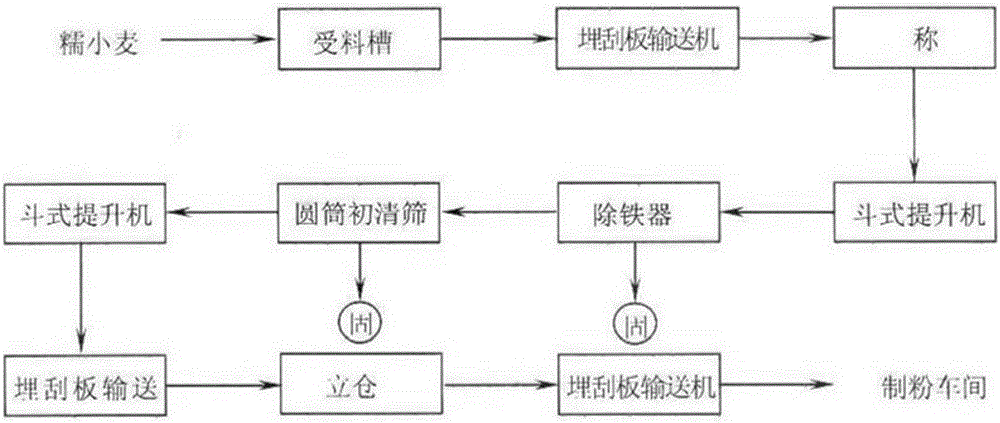

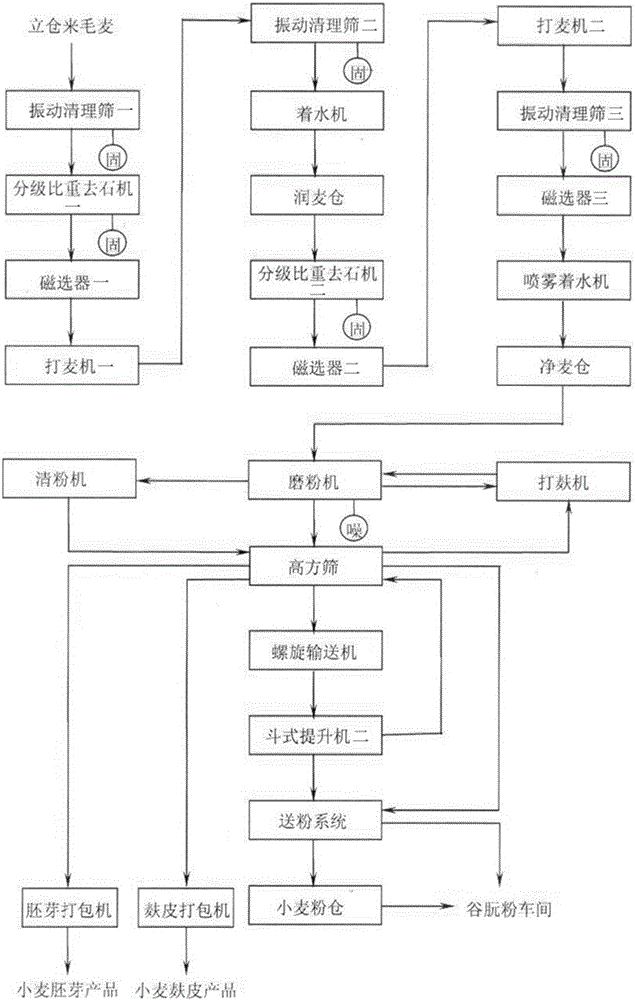

[0022] Such as figure 1 , figure 2 Shown, a kind of glutinous wheat milling process, comprises the following steps:

[0023] (1) Wheat cleaning: put the glutinous wheat into the receiving trough, and send it to the scale through the buried scraper conveyor. After weighing, it is lifted to the iron remover by the hoist to remove the ferromagnetic impurities in the material, and then transported to the initial stage of the cylinder. Clean the sieve to further remove impurities, and then lift it to the buried scraper conveyor 2 through the bucket elevator 1, transport it to the vertical warehouse, and then transport it to the milling workshop through the buried scraper conveyor 3;

[0024] (2) Run wheat:

[0025] The first moistening: transport the delivered wool wheat to the vibrating cleaning sieve 1 to remove impurities, and then sequentially transport it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com