Special automatic manipulator for continuous casting steel

A manipulator and automatic technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems such as easy failure, rigidity influence, and long distance, so as to ensure smooth production, reduce labor intensity, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

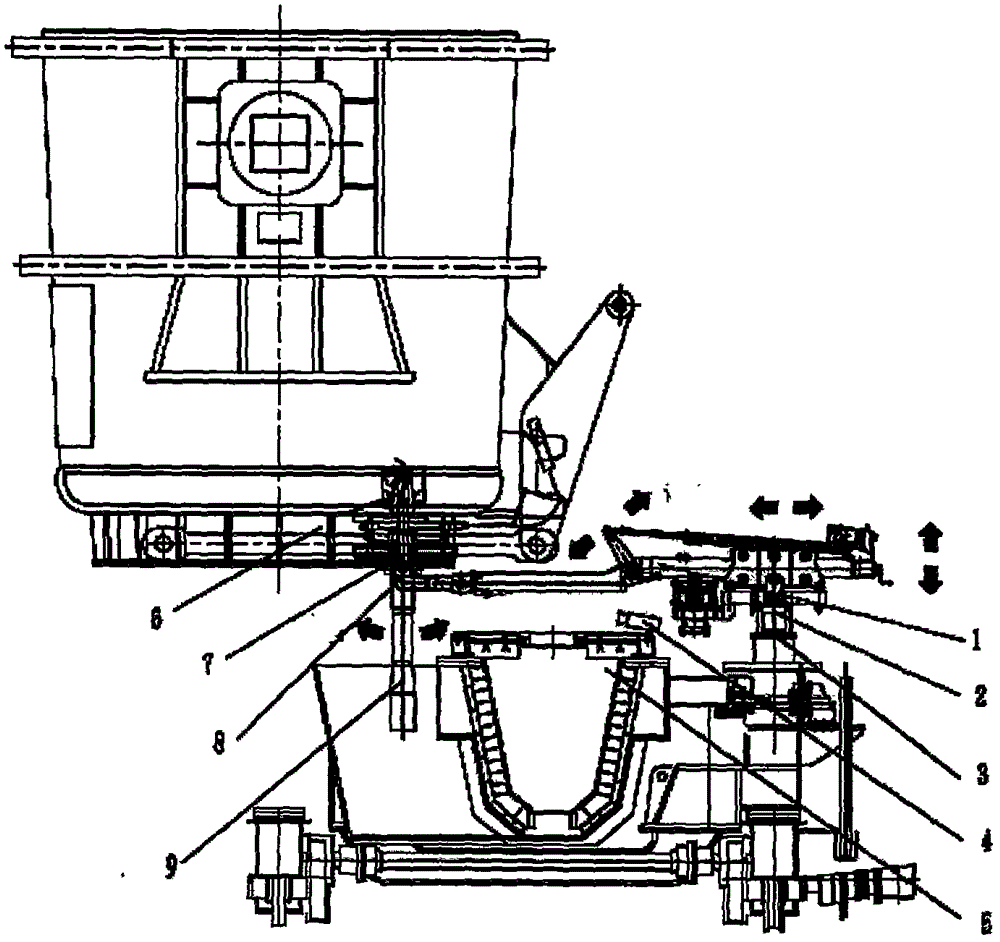

[0012] A special manipulator for continuous casting automatic steel pouring, anchored on the tundish car, clamping the shroud at the end, moving up and down, turning left and right through the sleeve, moving back and forth of the beam, turning over the end, through the handwheel, button , crank handle, and computer-calculated position information to realize the automatic docking of the long nozzle and the ladle discharge nozzle, and further open the slide plate to realize unmanned automatic steel pouring.

[0013] In this embodiment of the novel device, during use, the user of the guide flag can lift the guide flag manually or insert it on the fixed support, and the fixed support is placed on the shoulder and fixed by the shoulder strap , and the flagpole is a retractable structure, during the journey, the user of the guide flag can use the mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com