Micro spindle for fine machining

A kind of mechanical processing and fine technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems that the speed cannot fully meet the requirements, limit the miniaturization of micro-machine tools, and complex structures, etc., to achieve the advantages of rotation accuracy, Easy to guarantee machining accuracy and good balance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

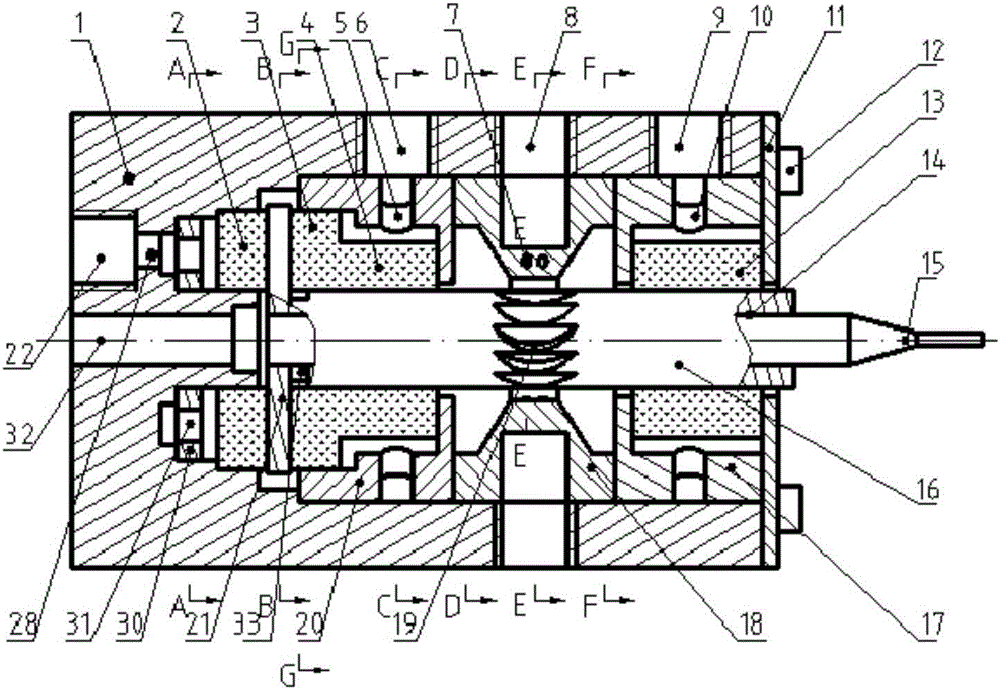

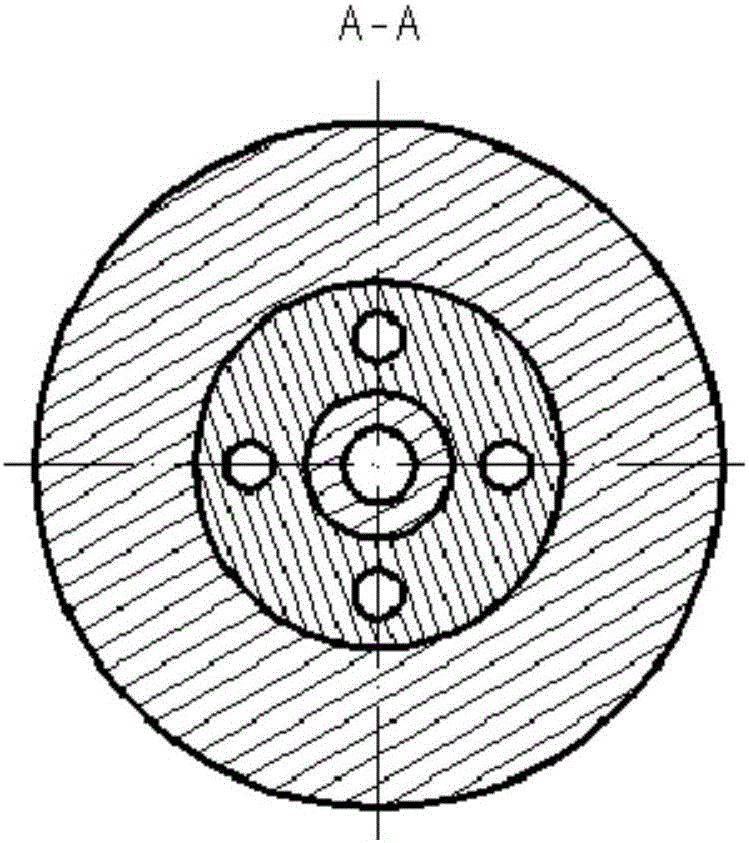

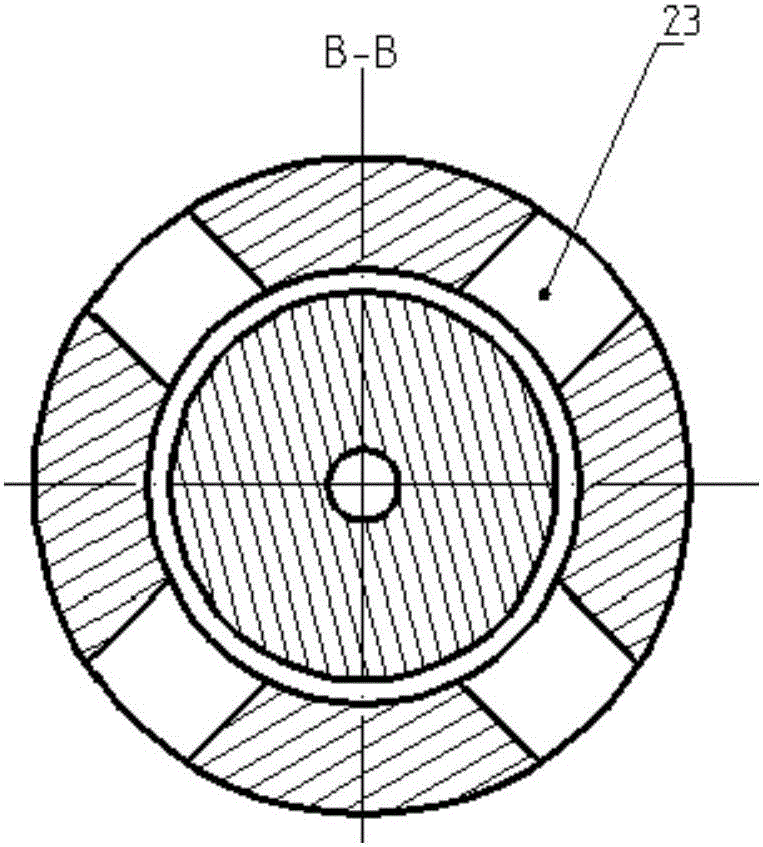

[0027] See attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 , the turbine 19 is directly processed in the middle of the main shaft rotor 16, that is, the turbine 19 and the main shaft rotor 16 are integrated, which avoids the installation error of the turbine 16, and the blades 29 on the turbine 19 are in a regular cylindrical shape, And facing the small hole 7 on the turbine nozzle 18, the turbine nozzle 18 is provided with two circles of small holes 7 to provide high-speed air flow to drive the spindle rotor 16 to rotate at a high speed, that is, to use a pneumatic micro-turbine to realize the ultra-high-speed rotation of the micro-spindle, so The front and rear ends of the main shaft rotor 16 are radially supported by the front porous static pressure gas radial bearing 13 and the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com