Plug cover drilling fixture

A technology for drilling jigs and plugging caps, which is applied in the direction of drilling/drilling equipment, clamping, manufacturing tools, etc., can solve the problems affecting the flatness of the end face of the plugging cap, waste of production resources, and the sealing of the plugging cap is not tight, etc., to achieve Improved convenience, ease of assembly, and the effect of facilitating the location of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is described in further detail:

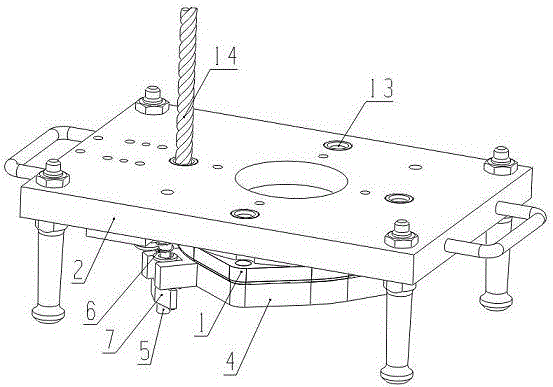

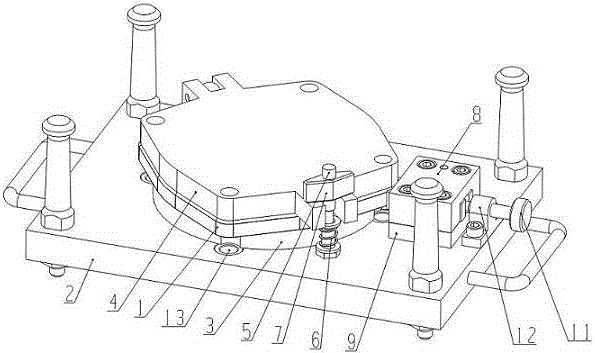

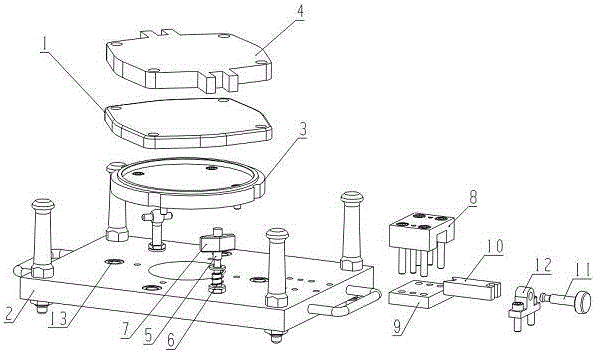

[0025] Such as Figure 1 to Figure 4 As shown, the present invention is a fixture used for the drilling process of the blocking cap 1, which includes a seat plate 2, a blocking cap clamping device and a positioning slider 10 for angularly positioning the blocking cap 1.

[0026] The four corner threads of the seat plate 2 are provided with four movable legs, and loosening nuts are also installed on the upper ends of the movable legs. The seat plate 2 is provided with drill bit 14 through holes, and a drill sleeve 13 is embedded in each through hole to guide and protect the drill bit 14 . The both sides of seat board 2 also are equipped with the handle that is convenient for worker's carrying. In actual use, the base plate 2 is placed on the rocker drill floor by using the legs, and then the drill bit 14 extends from the drill sleeve 13 to the bottom of the base plate 2 to dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com