Laser die cutting device for battery core pole lugs

A laser die-cutting and lug technology, which is applied to laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as equipment failure, tab deformation, and bumping into grooves, so as to avoid interference , Dust removal effect is good, and the effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings.

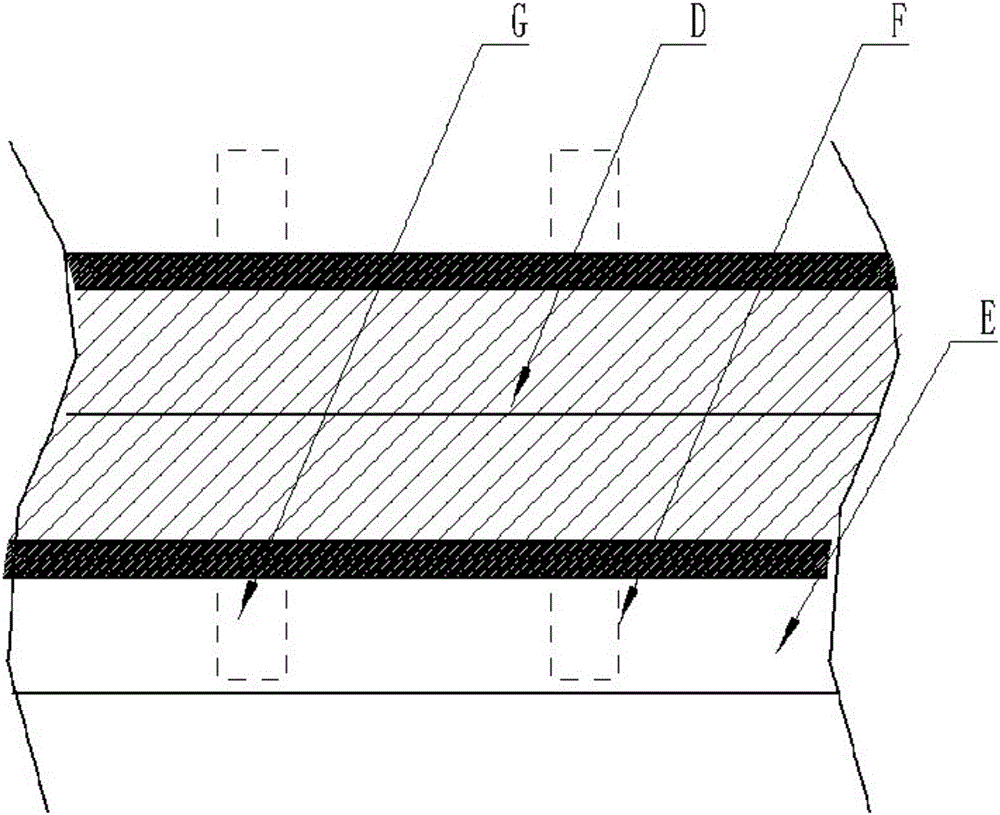

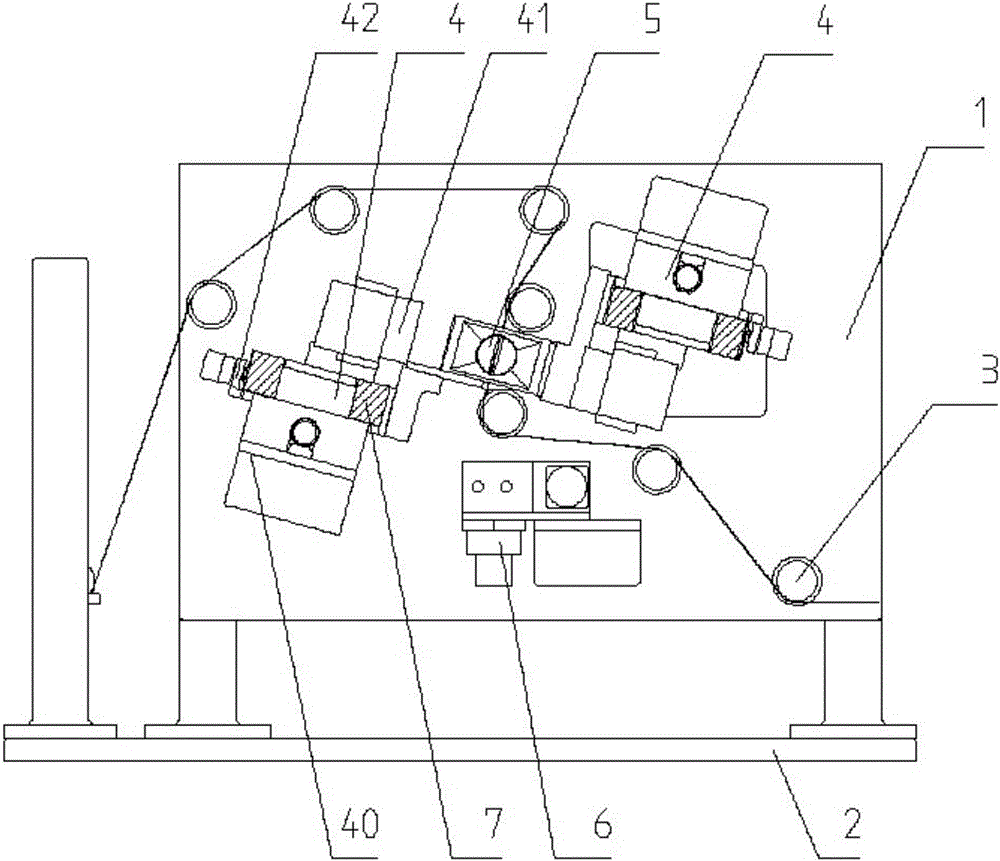

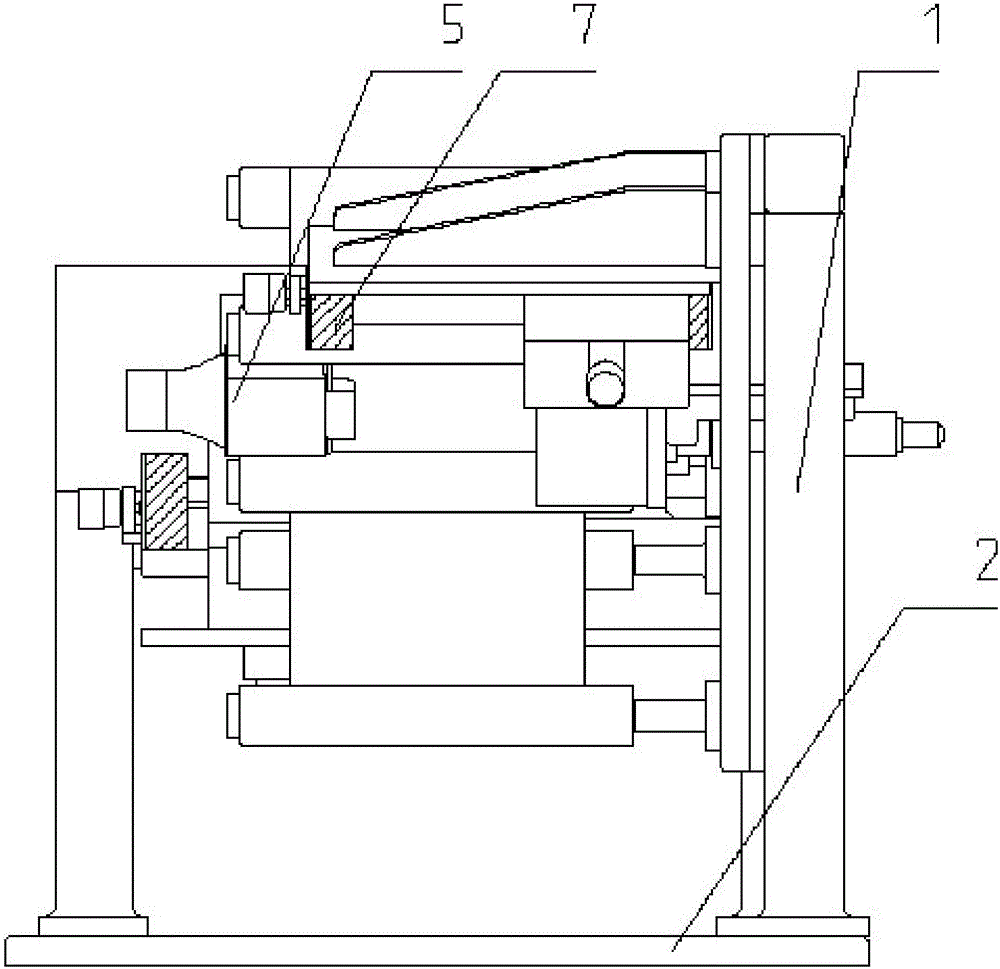

[0031] Such as Figure 2 to Figure 11 As shown: the battery tab laser die-cutting device includes a frame plate 1, a frame bottom plate 2, a roller 3, a laser die-cutting mechanism 4, a dust removal mechanism 5, a waste collection mechanism 6, a dust cover 7, a support Plate 40, laser head 41, adjustment mechanism 42, left side plate 51, right side plate 52, upper side plate 53, lower side plate 54, gap 55, laser channel 56, left air knife 57, right air knife 58, material box 61. Frequency conversion motor 62, second bottom plate 63, auxiliary roller 64, brush roller 65, pulley 66, first gear 67, second gear 68, material passage 69, first scale fine-tuning 401, line rail seat 402, the first A bottom plate 421 , an adjustment platform 422 , a second scale fine-tuning 423 , a first screw 424 , a screw nut 425 , a spacer 426 , a fixing plate 427 , a connecting plate 428 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com