Precision infusion device automatic assembling equipment filter material loading portion

An automatic assembly and filter technology, applied in metal processing equipment, assembly machines, metal processing, etc., can solve problems such as filter prolapse and affect filter feeding efficiency, achieve good stability, solve high labor cost output, The effect of stable and continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

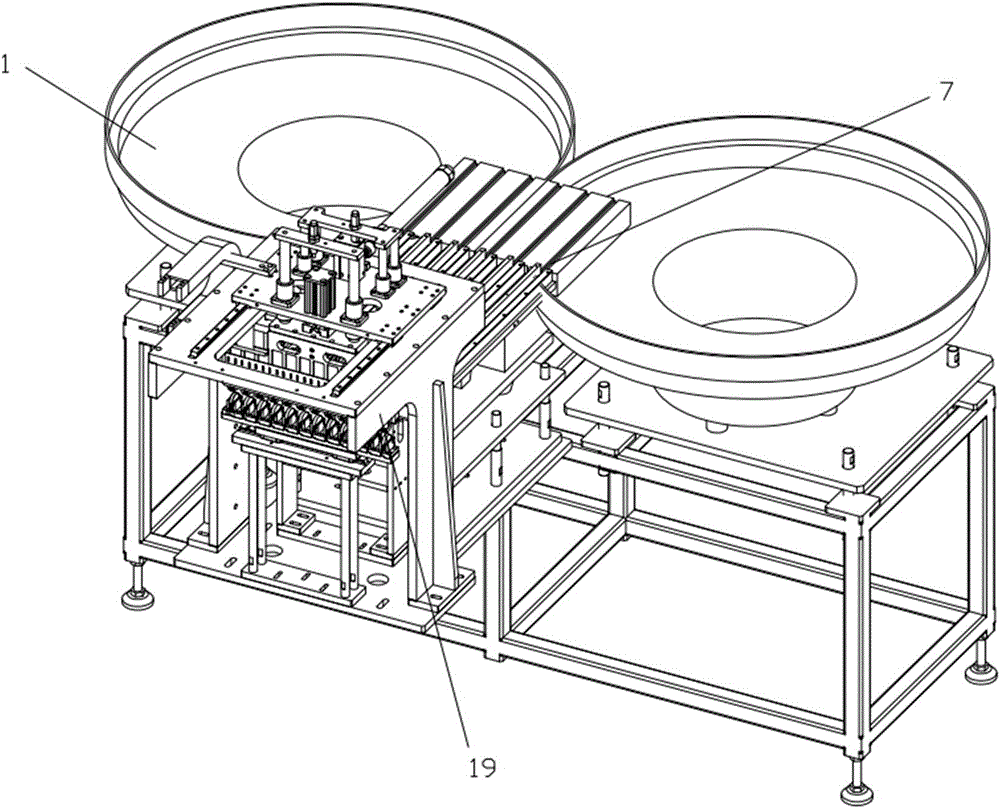

[0039] like Figure 1-9 As shown, the feeding part of the filter on the precision infusion set automatic assembly equipment provided in this embodiment includes:

[0040] Two groups of vibrating feeding devices 1;

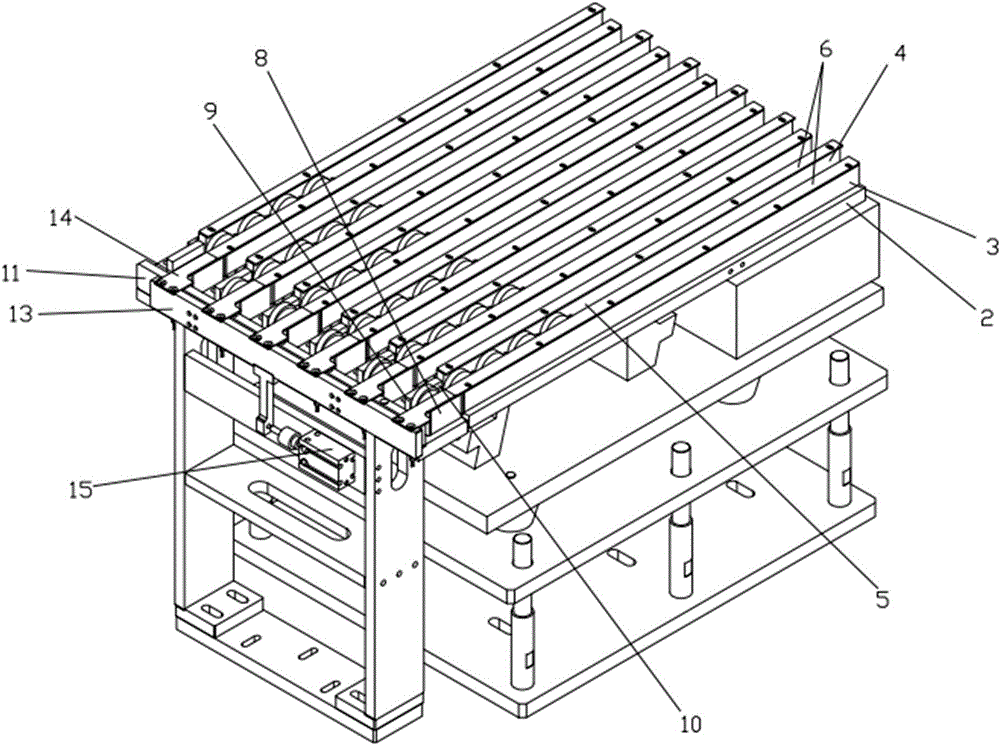

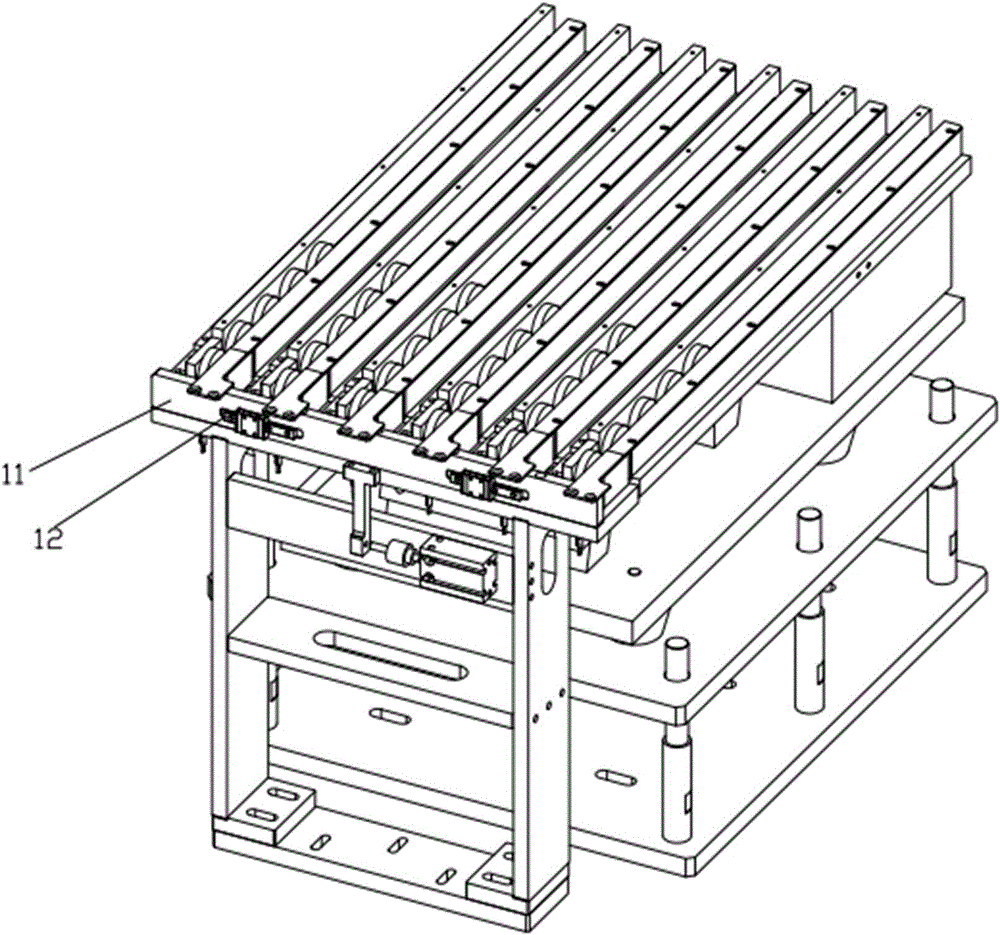

[0041] A discharge and flat delivery device, the discharge and flat delivery device includes a flat delivery base plate 2;

[0042] The first limiting block 3 and the second limiting block 4 arranged at intervals along the horizontal direction of the space on the bottom plate 2, wherein the first limiting block 3 and the second limiting block 4 are distributed alternately, and each The adjacent set of first limit block 3 and the second limit block 4 jointly form a flat feed and discharge channel 5 for conveying the filter, and between the first limit block 3 and the second limit block 4 There is a first pressure plate 6 that blocks the opening of the horizontal feeding and discharging channel 5 to prevent the filter in the horizontal feeding and discharging chann...

Embodiment 2

[0049] The feeding part of the filter on the precision infusion set automatic assembly equipment provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 10As shown, but in this embodiment, a pair of support arms 21 are symmetrically arranged on the flat feed bottom plate 2 of the discharge and flat feed device, and a pair of support arms 21 are jointly connected with a rotating shaft that can be rotated and adjusted around its central axis. 22. On the rotating shaft 22, there are six inspection installation seats 23 corresponding to the flat delivery and discharge passages 5 on the discharge and flat delivery device in series. Whether there is a through-beam photoelectric switch 24 for passing through the filter in the delivery and discharge channel 5.

[0050] In the above, six are added on the discharge and flat delivery device to correspond to the flat delivery and discharge channels 5 on the discharge and flat delivery device, and are...

Embodiment 3

[0052] The feeding part of the filter on the precision infusion set automatic assembly equipment provided in this embodiment, its general structure is consistent with embodiment 2, such as Figure 11 As shown, but the slide mechanism 19 in this embodiment also includes a pair of travel switches 25 , which are evenly distributed on the installation plane 16 and located at the two movement setting positions of the slide 192 .

[0053] In the above, a pair of travel switches 25 for real-time monitoring of whether the sliding table 192 is translated in place during each translation process along the first track is added to the sliding table mechanism 19, thereby monitoring the reclaiming manipulator assembly 20 on the sliding table 192 Whether the retrieving action is accurately completed, and at the same time, the signal that the retrieving manipulator assembly 20 on the sliding table 192 completes the corresponding action can be conveniently sent to the main control part of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com