Biomass fuel briquetting forming machine

A biomass fuel and forming machine technology, applied in the direction of material forming presses, stamping machines, presses, etc., can solve the problems that restrict the development of biomass fuel industry, the degree of automation is not high, and the equipment is easy to wear and tear, so as to achieve automation Mass production, good pressure effect and consistent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

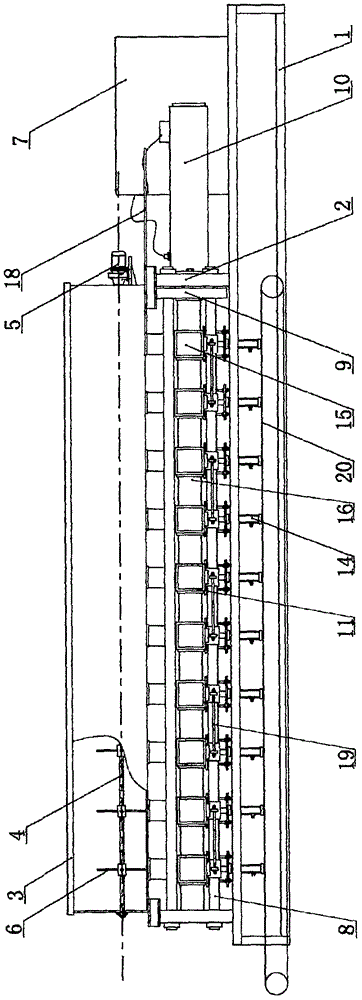

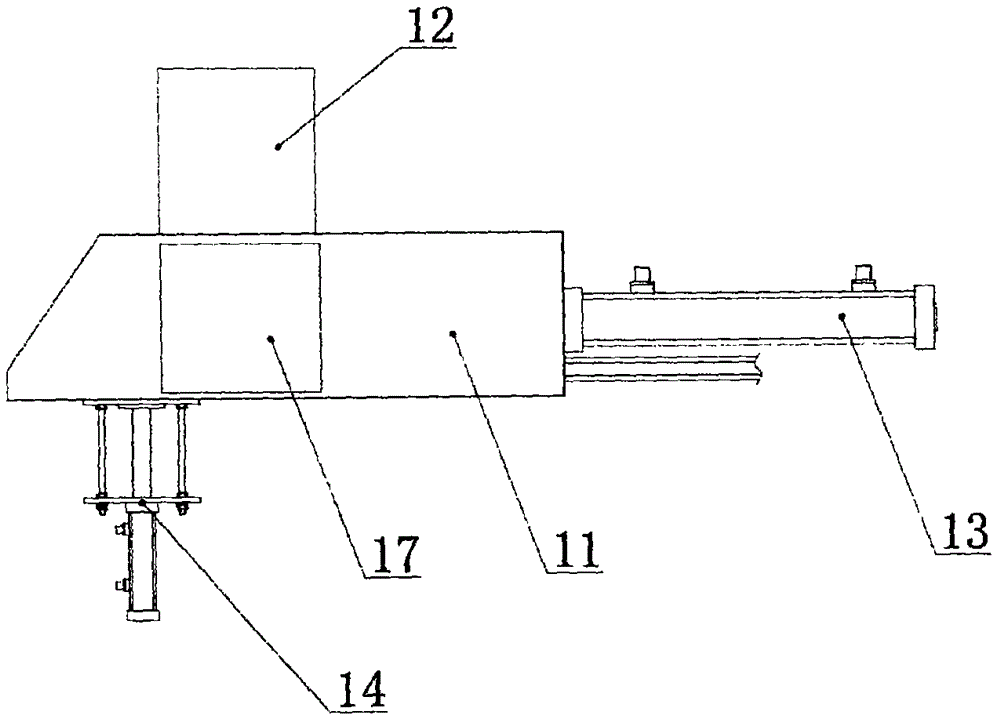

[0014] see figure 1 and figure 2 , a biomass fuel briquette forming machine, comprising a frame 1, two vertical plates 2 arranged at both ends of the frame 1, a support feed hopper 3 arranged on the top of the two vertical plates, and a molding machine arranged between the two vertical plates Components, and the hydraulic control system 7 arranged on the frame, the bulk material assembly is provided on the feed hopper, and the bulk material assembly includes a rotating shaft 4 pivotally arranged on the feeding hopper 3, a drive shaft The driving motor 5 and the stirring rod 6 provided with the rotating shaft; the molding assembly includes a plurality of supporting shafts 8 arranged in parallel between the two vertical plates, a multi-component mold unit slidingly sleeved on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com