Method of continuously preparing artificial rutile and dedicated device thereof

A technology of artificial rutile and special equipment, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems that conventional reactors cannot realize continuous large-scale production, and is suitable for large-scale production, overcomes high energy consumption, and solves the problem of The effect of particle shrinkage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

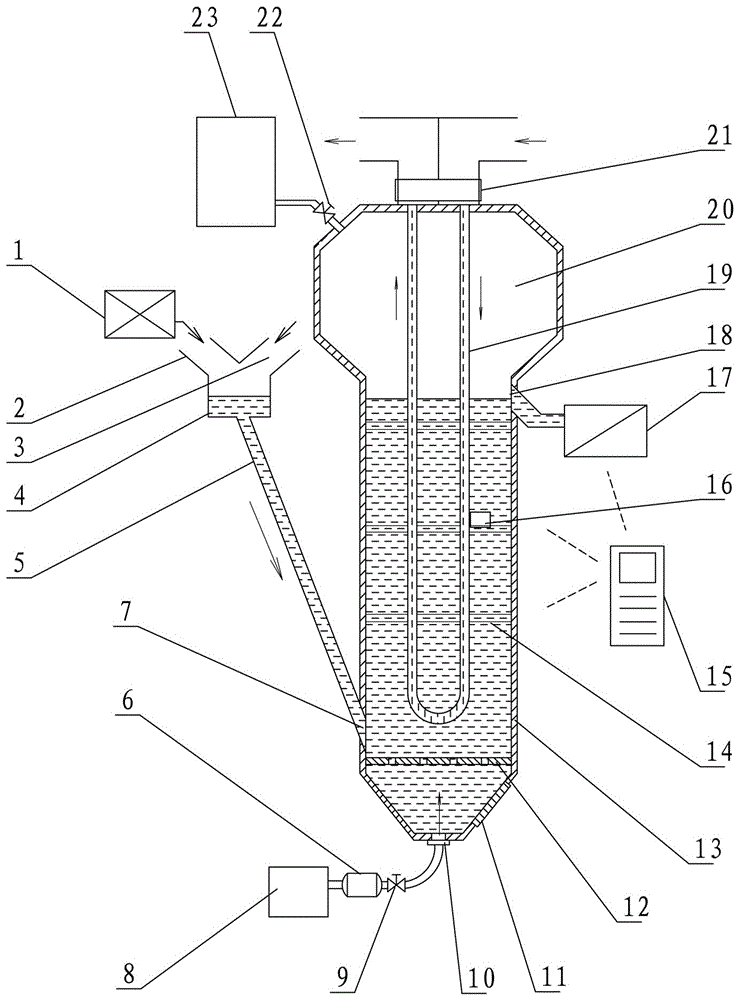

[0023] The following is attached figure 1 Embodiments of the present invention are further described in detail. The present invention is a method for continuously preparing artificial rutile, such as figure 1 As shown, the method can be implemented using the following special equipment, that is, a special equipment for continuous preparation of artificial rutile. The main body of the special equipment is a vertical hydrochloric acid-resistant fluidized bed reactor 13, which is set at a high position outside the reactor. There is a mixing bin 4. The height of the mixing bin is close to the top of the reactor. The upper part of the mixing bin is provided with a hydrochloric acid inlet 3 and a material inlet 2 of the mixing bin. The hydrochloric acid inlet and the material inlet of the mixing bin are arranged oppositely. The inlet can adopt an included angle of 100 degrees to 175 degrees, so that the added acid liquid and granular materials form a mixed slurry material, and a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com