Reagent for preparing reusing petroleum drilling wastewater into slurry for reuse and application thereof

A technology for oil drilling and wastewater, applied in mining wastewater treatment, earth-moving drilling, wellbore flushing, etc., can solve the problems of reducing mud viscosity, hidden danger of sticking, reducing mud viscosity and other performance problems, and achieves the effect of improving suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A reagent for slurry reuse of oil drilling wastewater:

[0031] A kind of reagent that is used for the slurry reuse of petroleum drilling waste water is made up of ion removal agent and filtrate conversion agent, and described ion removal agent comprises the sodium carbonate (soda ash) that adds first and the sodium hydroxide (caustic soda) that adds afterwards; The described The filtrate conversion agent is JDKJ-2, an anti-salt fluid loss reducer for drilling fluid; the mass-volume ratio of sodium carbonate to oil drilling wastewater is 5.5-8.5kg / m 3 , the mass volume ratio of sodium hydroxide to oil drilling wastewater is 0.45-0.65kg / m 3 ; The mass-to-volume ratio of salt-resistant fluid loss reducer JDKJ-2 for drilling fluid to oil drilling wastewater is 3-4kg / m 3 .

Embodiment 2

[0032] Example 2: Application of a reagent for the reuse of oil drilling waste water mixing slurry:

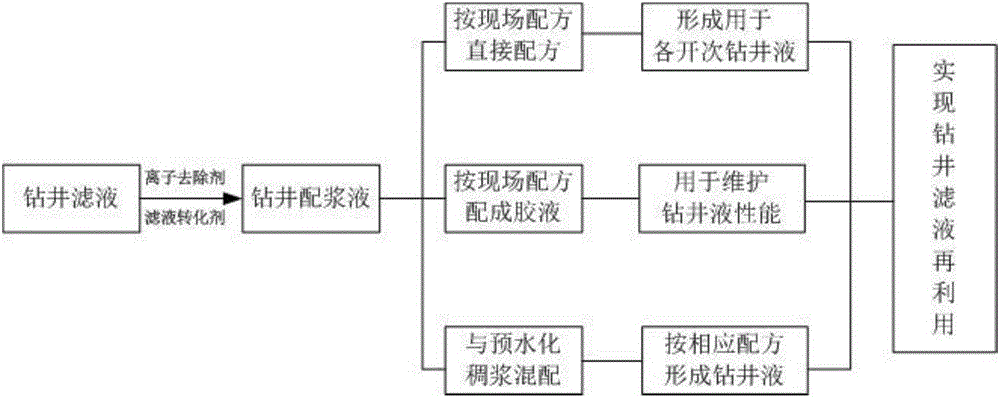

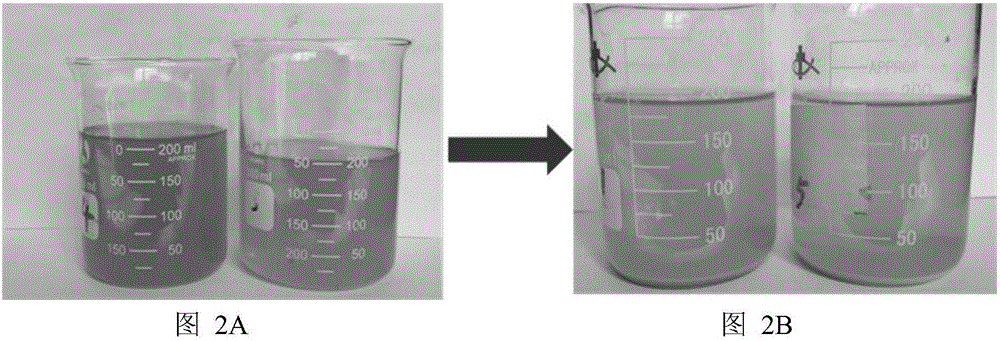

[0033] The usage method of a kind of reagent that is used for the reuse of slurry preparation of petroleum drilling wastewater as described in embodiment 1 is: add ion removal agent and filtrate conversion agent in embodiment 1 to petroleum drilling wastewater, wherein sodium carbonate is added first to make wastewater The pH value of the waste water reaches 9; then sodium hydroxide is added to make the pH value of the wastewater reach 12; finally, the anti-salt fluid loss reducer JDKJ-2 is added to treat the filtrate into drilling fluid. Drilling slurry preparation realizes the reuse of drilling filtrate through the following three ways (such as figure 1 shown):

[0034] (1) Drilling slurry can be directly mixed on site to form drilling fluid for each drilling;

[0035] (2) Drilling slurry can be formulated into glue to maintain the performance of drilling fluid; or

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com