Composite titanium dioxide and preparation method thereof

A rutile-type titanium dioxide and titanium dioxide technology, applied in the field of chemical biology, can solve the problem of high cost of titanium dioxide, achieve better particle size distribution, reduce thermoplasticity, and improve the hardness of the coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

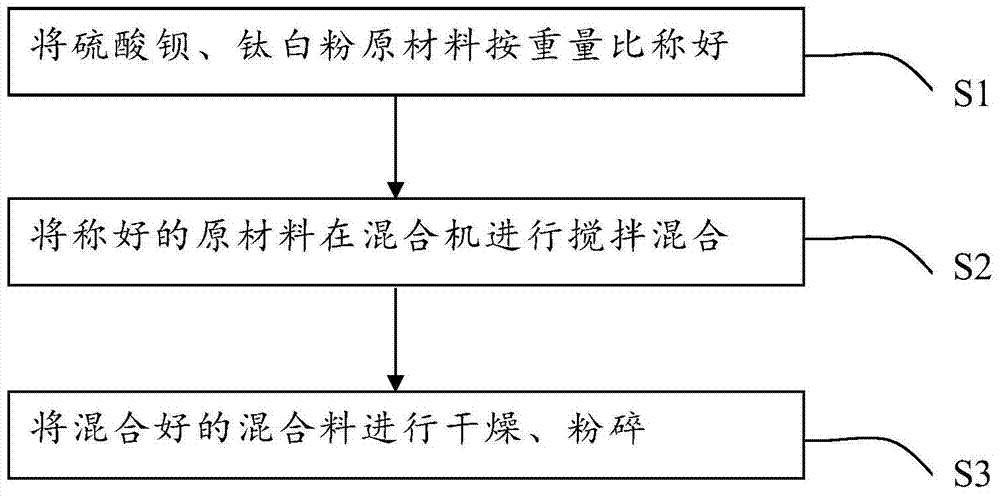

[0032] Such as figure 1 As shown, the present invention also discloses a preparation method of composite titanium dioxide, comprising the following steps:

[0033] Weigh barium sulfate and titanium dioxide raw materials by weight;

[0034] Stir and mix the weighed raw materials in a mixer;

[0035] The mixed mixture is dried and pulverized.

[0036] In practical application, if the whiteness of the composite titanium dioxide is not enough, we can add whitening agent when the weighed raw materials are stirred and mixed in the mixer, so that the whiteness of the composite titanium dioxide can be improved to a certain extent; The weight ratio range of barium sulfate is 45-20%, the weight ratio range of titanium dioxide is 55-80%, and the optimal proportion scheme is that the weight ratio of barium sulfate is 20%, and the weight ratio of titanium dioxide is 80%; in addition, The titanium dioxide is anatase or rutile titanium dioxide, the barium sulfate is modified precipitated ...

Embodiment 1

[0038] Embodiment one: a kind of composite type titanium dioxide preparation method, comprises the following steps:

[0039] Step S1: weighing barium sulfate and titanium dioxide raw materials according to weight ratio;

[0040] Use anatase or rutile titanium dioxide for titanium dioxide, and use modified precipitated ultrafine barium sulfate for barium sulfate. When selecting raw materials titanium dioxide and barium sulfate, try to choose a whiter hue to improve the whiteness of the composite titanium dioxide. , the ratio of raw materials is: the weight ratio of barium sulfate is 20%, the weight ratio of titanium dioxide is 80%, and the raw materials of barium sulfate and titanium dioxide are weighed according to the weight ratio.

[0041] Step S2: stirring and mixing the weighed raw materials in a mixer;

[0042] Users can choose cone mixer or horizontal mixer according to their own needs, and horizontal mixer is preferred. According to the workload of the mixer, the proce...

Embodiment 2

[0045] Embodiment two: a kind of composite type titanium dioxide preparation method, comprises the following steps:

[0046] Step S1: weighing barium sulfate and titanium dioxide raw materials according to weight ratio;

[0047] Use anatase or rutile titanium dioxide for titanium dioxide, and use modified precipitated ultrafine barium sulfate for barium sulfate. When selecting raw materials titanium dioxide and barium sulfate, try to choose a whiter hue to improve the whiteness of the composite titanium dioxide. The ratio of raw materials is: the weight ratio of barium sulfate is 30%, the weight ratio of titanium dioxide is 70%, and the raw materials of barium sulfate and titanium dioxide are weighed according to the weight ratio.

[0048] Step S2: stirring and mixing the weighed raw materials in a mixer;

[0049]Users can choose cone mixer or horizontal mixer according to their own needs, and horizontal mixer is preferred. According to the workload of the mixer, the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com