Flow line type multicolor ceramic as well as preparation method and application thereof

A technology of flow pattern and ceramics, which is applied in the field of flow pattern multi-color ceramics and its preparation, can solve the problems of high wear resistance and scratch resistance of colored glaze ceramics, difficulties in technical realization, and no relevant reports, etc., to achieve appearance performance Strong force, good quality, increase the effect of density uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

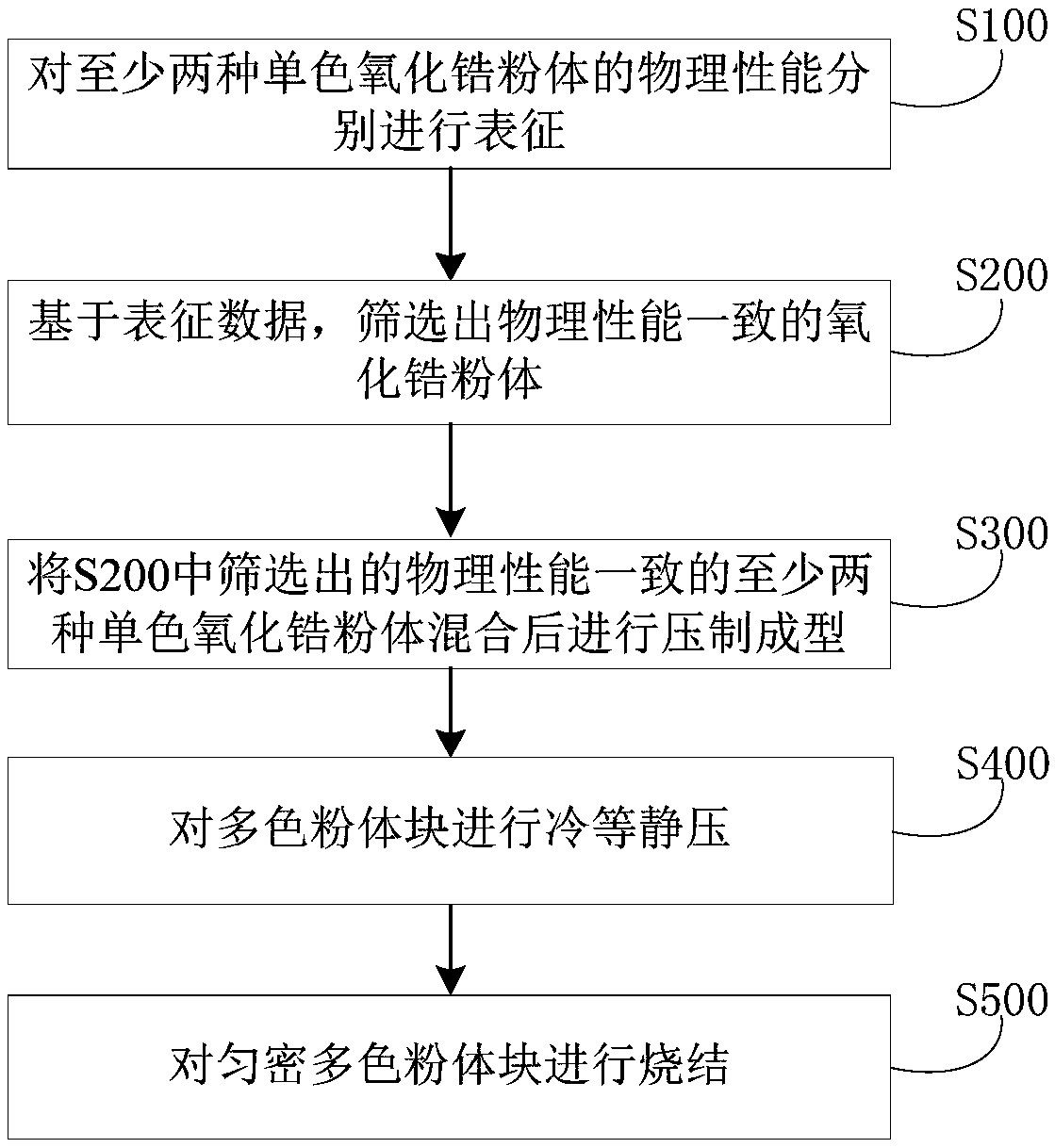

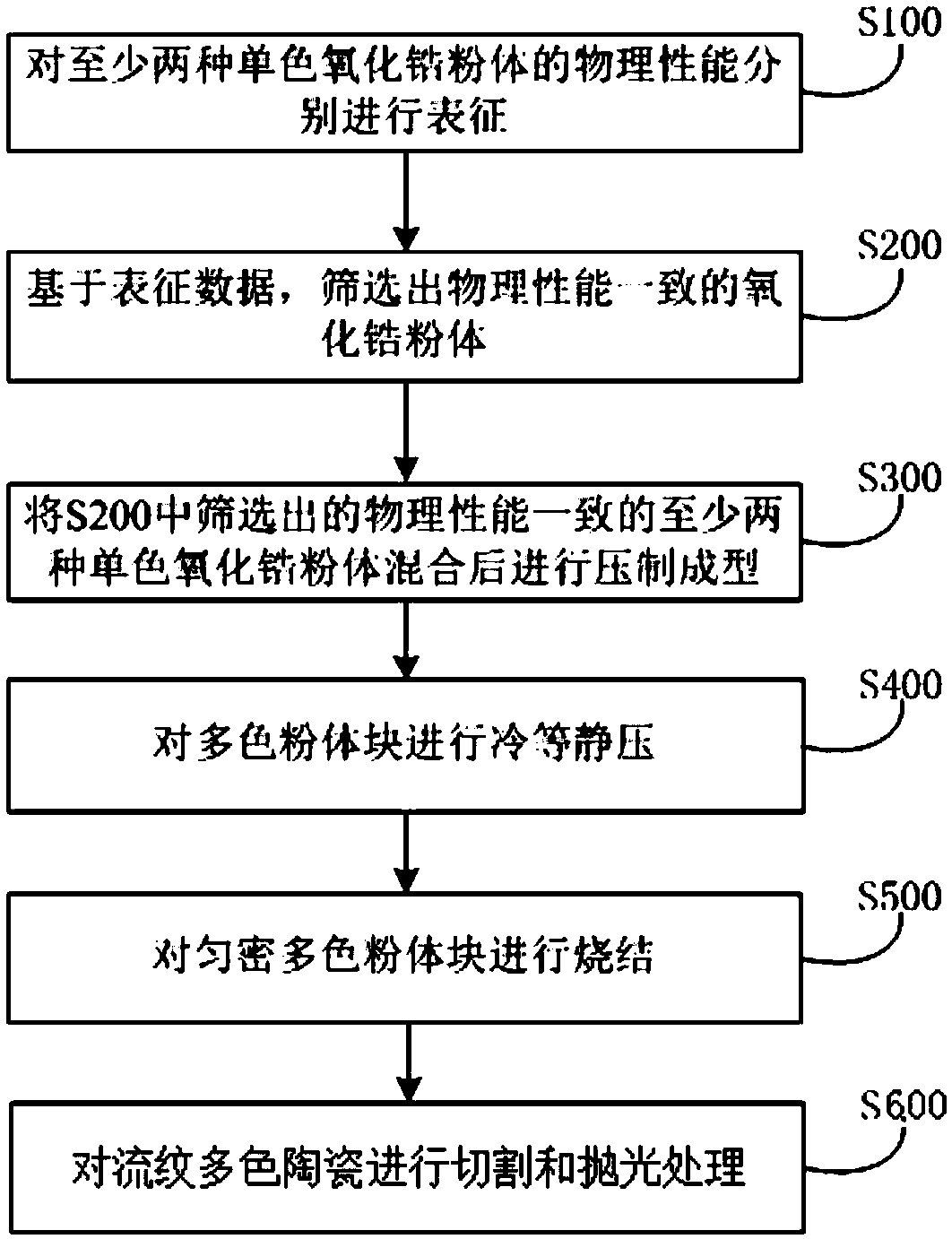

Method used

Image

Examples

preparation example Construction

[0048] According to the method for preparing rhyolite multi-color ceramics according to the embodiment of the present invention, by using zirconia powder with consistent physical properties to prepare rhyolite multi-color ceramics, in the molding process, the particle gradation consistency can be made good, and the powder inside the green body Good packing and filling properties, the number of residual pores of multi-color powder blocks is significantly reduced, and the distribution of residual pores is significantly improved, and when pressing at least two kinds of single-color zirconia powders, the color selection of each powder The texture pattern of the final flow pattern multi-color ceramics is determined by the pressing form; by cold isostatic pressing of the multi-color powder block, the density uniformity of the multi-color powder block can be significantly increased, thereby improving the final flow pattern. In the sintering process, zirconia powders with consistent ph...

Embodiment 1

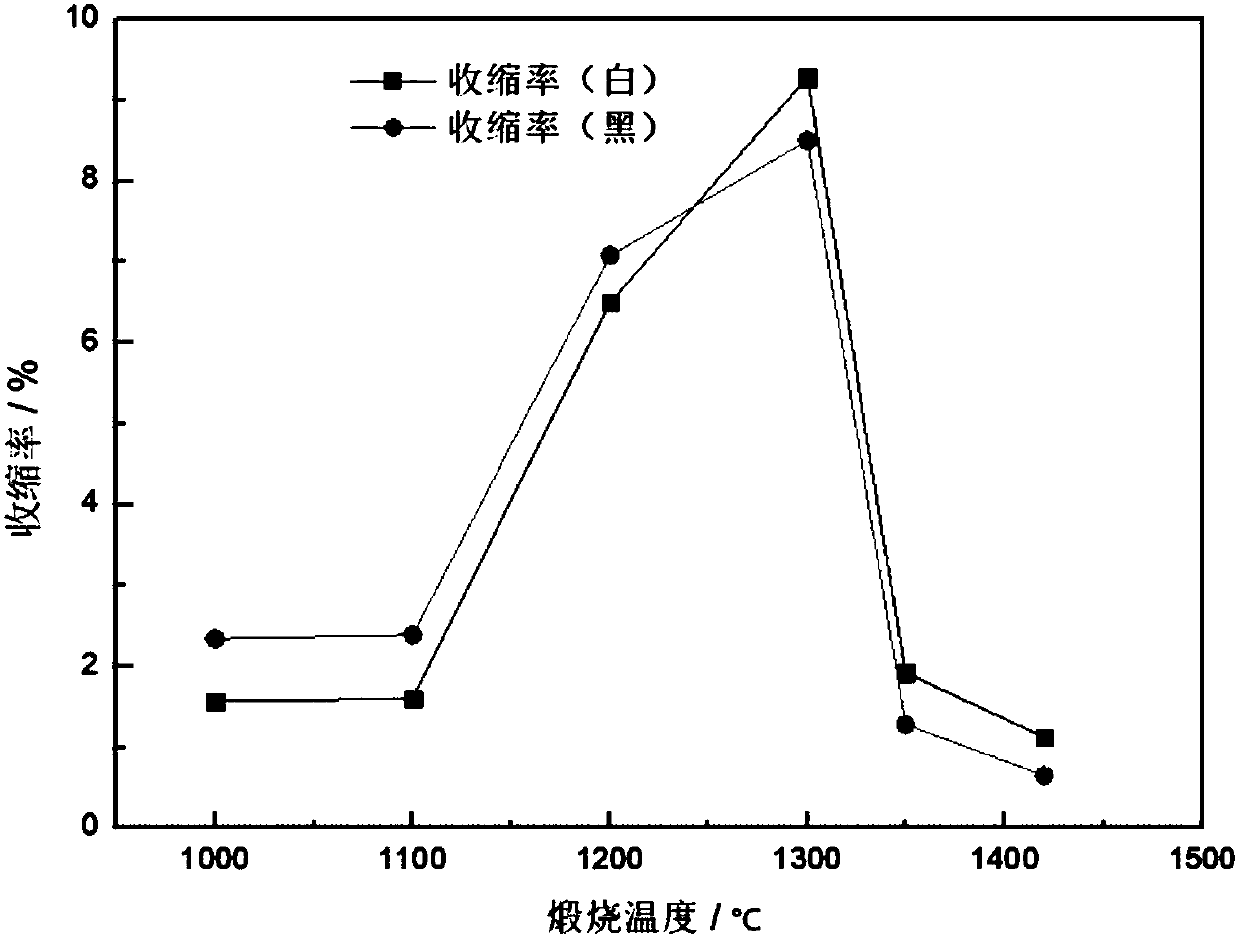

[0058] After the above tests, black and white yttrium-stabilized zirconia powders were selected, and the shrinkage values of the two at various temperatures are as follows: image 3 As shown, the mass ratio of black and white yttrium stabilized zirconia powder is 9:1. When performing press molding, a mesh plate is used for cloth. The yttrium-stabilized zirconia powder is put into the mold in 3 times, first take 60wt% of the black yttrium-stabilized zirconia powder, then take 100wt% of the white yttrium-stabilized zirconia powder, and finally take the remaining 40wt% of the black yttrium-stabilized zirconia powder The zirconium powder is distributed, and molded under the conditions of 18MPa and holding pressure for 20s to obtain a multi-color powder block, and a total of 10 multi-color powder blocks are prepared according to the same formula and method;

[0059] The above 10 multi-color powder blocks were subjected to cold isostatic pressing for 15 minutes under a cold isost...

Embodiment 2

[0064] After the above tests, black and white yttrium-stabilized zirconia powders were selected, and the mass ratio of black and white yttrium-stabilized zirconia powders was 8:2. When performing press molding, a mesh plate is used for cloth. The yttrium-stabilized zirconia powder is divided into three times into the mold, the first time takes 60% of the black yttrium-stabilized zirconia powder, then takes 100% of the white yttrium-stabilized zirconia powder, and finally takes the remaining 40% of the black yttrium-stabilized zirconia powder The zirconium powder is distributed, and molded under the conditions of 18MPa and holding pressure for 20s to obtain a multi-color powder block, and a total of 10 multi-color powder blocks are prepared according to the same formula and method;

[0065] The above 10 multi-color powder blocks were subjected to cold isostatic pressing for 15 minutes under a cold isostatic pressure of 160 MPa to obtain uniform and dense multi-color split block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com