Heat-resistant ceramic utensil and preparation method thereof

A technology for ceramics and utensils, applied in the field of heat-resistant ceramic utensils and their preparation, can solve problems such as easy burning and cracking, and achieve the effect of wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A kind of preparation method of heat-resistant ceramic utensil provided by the present invention, comprises the following steps:

[0017] S1. Pretreatment of various raw materials for preparing ceramic utensils: manual selection and crushing of raw materials.

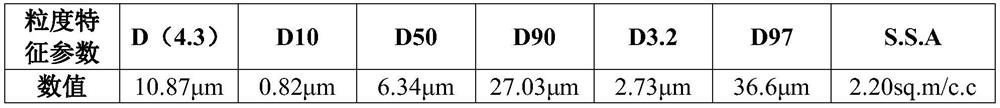

[0018] S2. Add purple wood, hard clay, soft clay, quartz, calcined talc and alumina that have been pretreated in S1 into the ball mill. Lithium feldspar is divided into four parts and then added in stages. Add the first portion of lithium petalite into the ball mill, grind finely for 1 hour, add the second portion of lithium petalite, and add the third portion of lithium petalite after fine grinding for 2 hours. In the invention, the petalite feldspar is finely ground three times to ensure the rationality of raw material particle distribution. When the fineness of lithium feldspar in the ball mill is 0.3-0.5%, pour the raw materials in the ball mill into the mud pool, add the fourth part of lithium feldspar, st...

Embodiment 1

[0038] The raw materials of the embryo body are: petalite feldspar 50%, purple wood knot 10%, hard clay 15%, soft clay 10%, quartz 10%, calcined talc 3% and alumina 2%. Additional additives were added at 5%.

[0039] S1. Carry out manual preliminary selection of the above-mentioned raw materials, test burn and select them, and use a ball mill to grind them finely by wet method.

[0040] S2. Add 10% of purple wood knots pretreated by S1, 15% of hard clay, 10% of soft clay, 10% of quartz, 3% of burnt talc, and 2% of alumina into the ball mill. Lithium feldspar is divided into four parts and then added in stages. Add the first portion of lithium petalite into the ball mill, grind finely for 1 hour, add the second portion of lithium petalite, and add the third portion of lithium petalite after fine grinding for 2 hours. When the fineness of lithium feldspar in the ball mill is 0.3-0.5%, pour the raw materials in the ball mill into the mud pool, add the fourth part of lithium fel...

Embodiment 2

[0053] The raw materials of the embryo body are: 45% petalite feldspar, 14% purple wood knot, 15% hard clay, 10% soft clay, 10% quartz, 3% burnt talc and 3% alumina, and add 8% additives.

[0054] Glaze formula: petalite 50%, spodumene 10%, quartz 16%, bovine bone 3%, kaolin 7%, barium carbonate 2%, calcite 3%, talc 5%, zinc oxide 3%, oxide Nickel 1%. In addition, 0.5% of rare earth and 13.5% of additives are added.

[0055] The method for preparing ceramic casserole is the same as embodiment 1.

[0056] Heat the 6L ceramic casserole produced in Example 1 and Example 2 to 1100°C in a high-temperature electric furnace, open the furnace door suddenly, and quickly put the reddened casserole into cold water with iron clips. No cracks are seen, and the products produced continuously are stable in thermal shock resistance.

[0057] The existing casserole pots with spodumene as the main raw material on the market generally have thermal shock resistance not exceeding 600°C-20°C wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com