Sewage and sludge treatment system and environmental-friendly recycling method thereof

A sewage sludge and treatment system technology, applied in the direction of sludge treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low energy recovery and utilization rate of sewage sludge and difficult to achieve effluent quality Discharge standards, sewage and sludge are difficult to reduce energy consumption and other issues, to achieve the effect of environmental protection treatment and reuse, significant energy saving and environmental protection effect, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

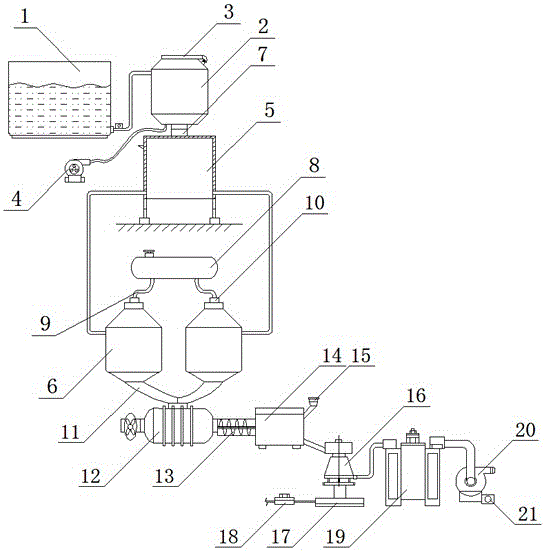

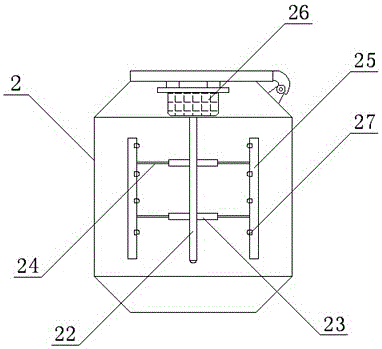

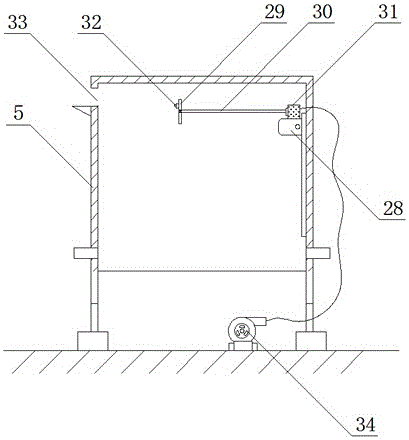

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] see Figure 1 to Figure 3 , a sewage sludge treatment system of the present invention and its environmental protection reuse method, comprising a collection tank 1, characterized in that: the bottom of the collection tank 1 is connected to the sludge treatment device 2, and the upper end of the sludge treatment device 2 A movable cover 3 is provided, and the bottom of the sludge treatment device 2 is connected with an external air blower 4 through a pipeline. The bottom of the sludge treatment device 2 is provided with a discharge port, and a control valve 7 is installed on the discharge port. A sludge settling tube 5 is installed directly below, and more than one anaerobic reaction device 6 is arranged on the outside of the sludge settling tube 5, and a solenoid valve is arranged between the sludge settling tube 5 and each ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com