A kind of oil well cement retarder and its preparation method and application

A technology of oil well cement and retarder, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance and high temperature sensitivity, and achieve good adaptability, good dosage linearity, The effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

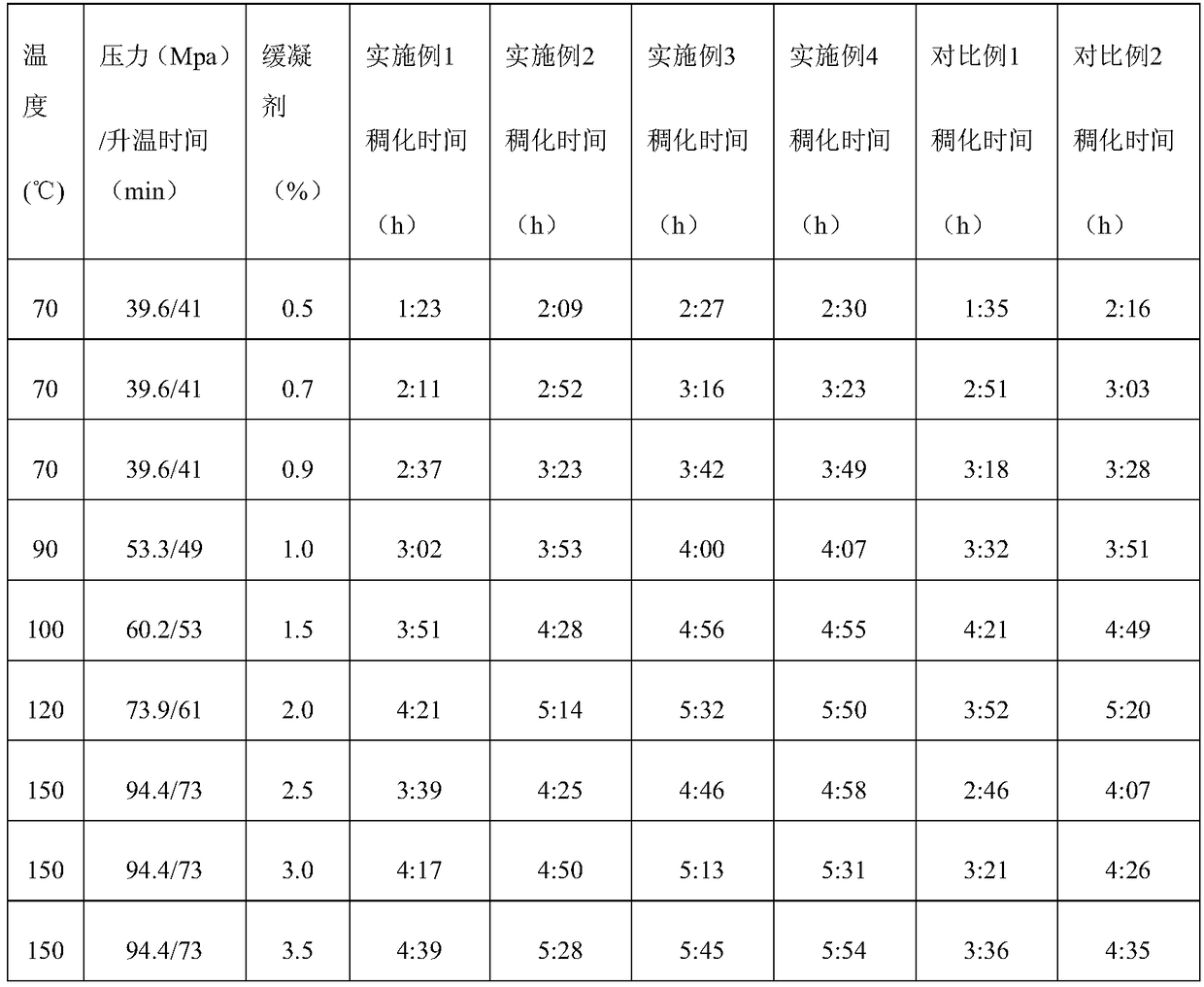

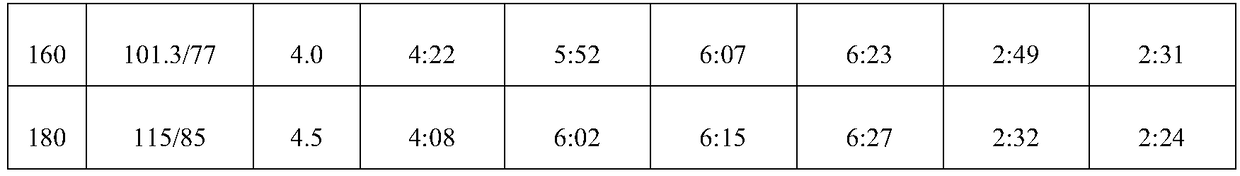

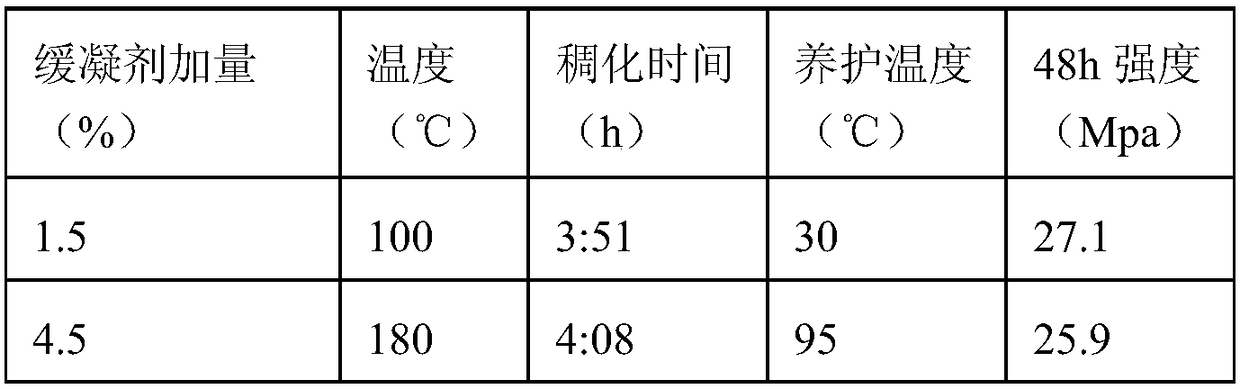

Examples

Embodiment 1

[0040] 100 parts of water, 3 parts of sodium glucoheptonate dihydrate, 8 parts of 1-adamantaneethylamine, 10 parts of phosphorous acid, and 1 part of concentrated hydrochloric acid were added to the water, heated to 60°C under stirring, and kept for 10 minutes; then 10 parts of formaldehyde solution was added dropwise under stirring state, and the dropwise addition was completed within 1 hour; the temperature was raised to 80° C., and kept under stirring state for 1 hour to obtain the oil well cement retarder.

Embodiment 2

[0042] 100 parts of water, 4 parts of sodium glucoheptonate dihydrate, 9 parts of 1-adamantaneethylamine, 11 parts of phosphorous acid, and 2 parts of concentrated hydrochloric acid were added to the water, heated to 80°C under stirring, and kept for 1 hour; then 12 parts of formaldehyde solution was added dropwise under stirring state, and the dropwise addition was completed within 1 hour; the temperature was raised to 120° C., and kept under stirring state for 5 hours to obtain the oil well cement retarder.

Embodiment 3

[0044] 100 parts of water, 4 parts of sodium glucoheptonate dihydrate, 10 parts of 1-adamantaneethylamine, 11 parts of phosphorous acid, and 3 parts of concentrated hydrochloric acid were added to the water, heated to 70°C under stirring, and kept for 0.5 hours; then 11 parts of formaldehyde solution was added dropwise under stirring state, and the dropwise addition was completed within 1 hour; the temperature was raised to 100° C., and kept under stirring state for 3 hours to obtain the oil well cement retarder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com