Method for preparing elastic epoxy resin for epoxy resin casting dry-type transformer

A dry-type transformer and epoxy resin technology, which is applied in the field of epoxy resin toughening, can solve problems such as difficulty in meeting the requirements of dry-type transformers, and achieve good mechanical properties, good compatibility, and improved cracking resistance and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

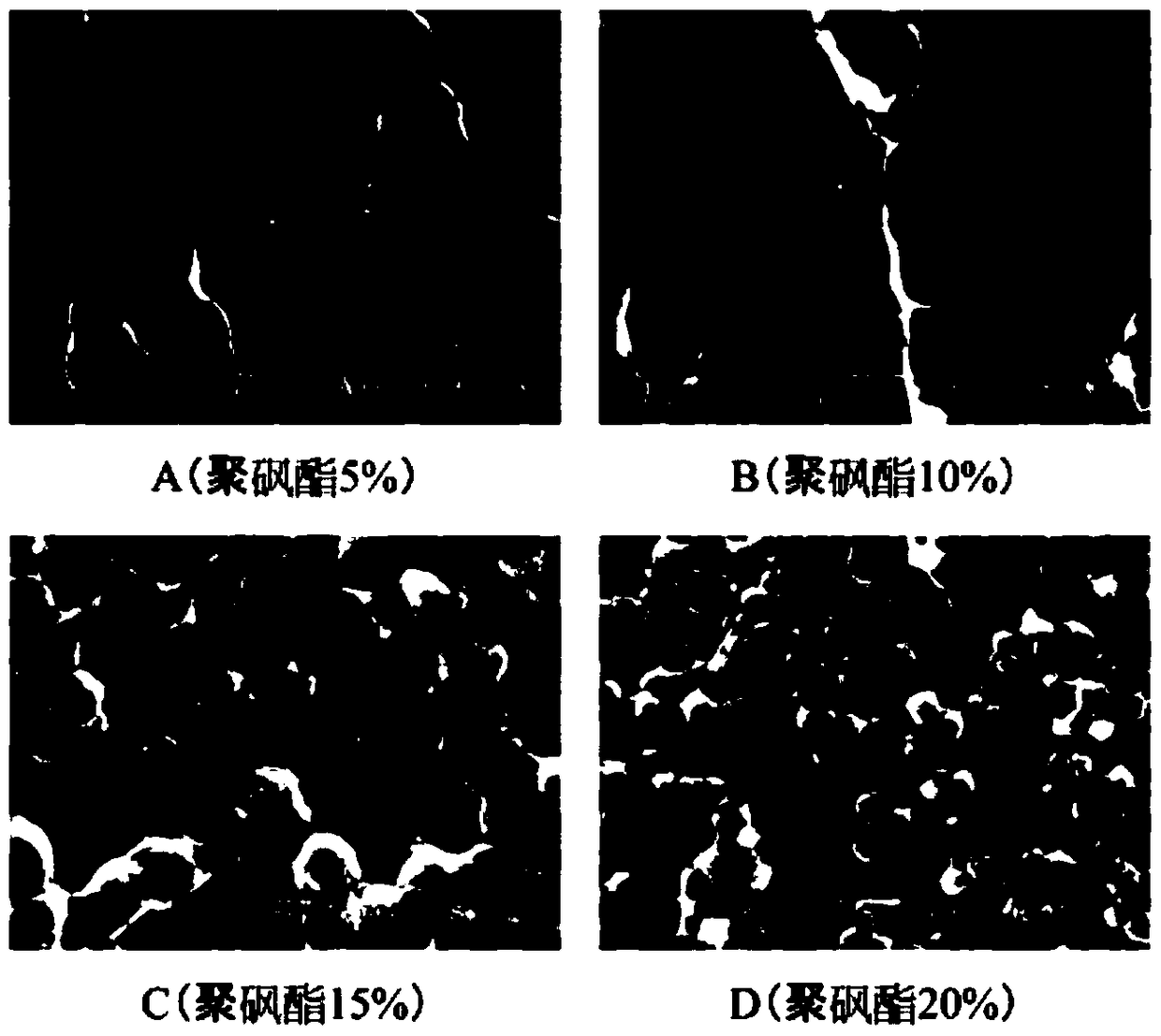

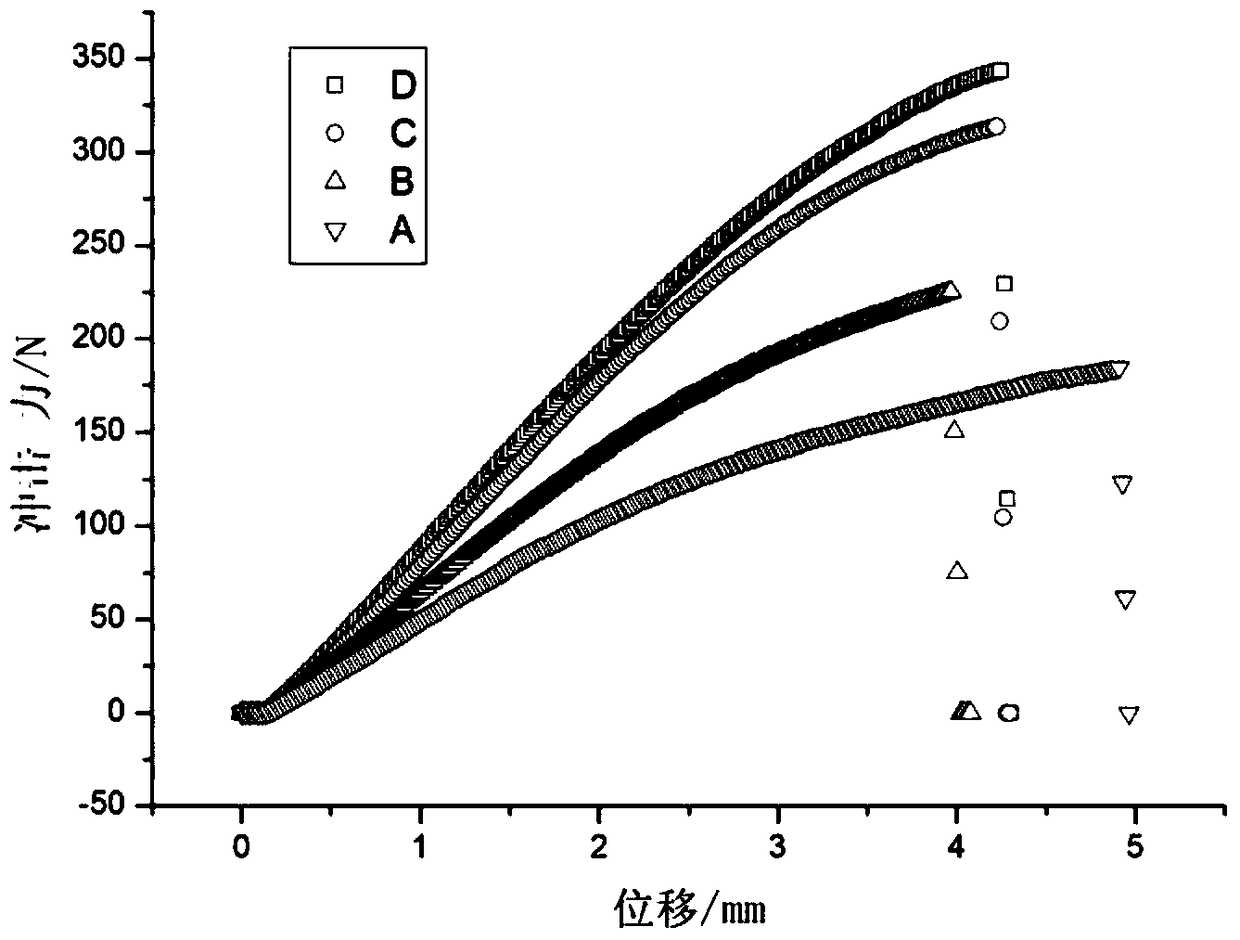

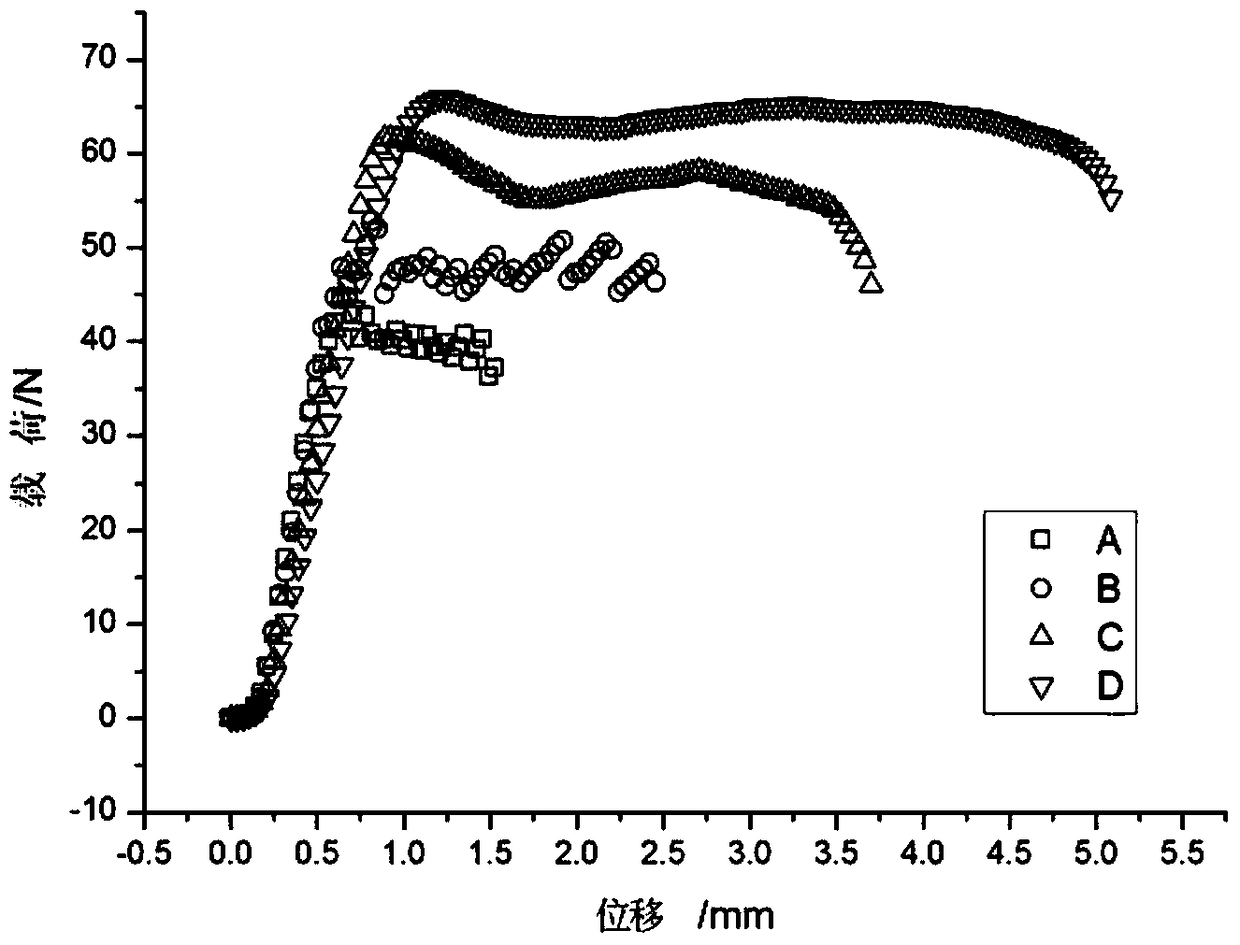

[0033] (1) Mix polysulfone ester and acid anhydride curing agent methyltetrahydrophthalic anhydride (MTHPA) according to the ratio of 10 parts: 85 parts, and stir for 1 hour at 130-150°C, so that polysulfone ester is fully dissolved in methyltetrahydrophthalic anhydride , and then add 0.3 parts of catalyst, such as benzyl dimethylamine, to obtain a transparent viscous solution; then bisphenol A epoxy resin and prepared polysulfone ester / methyltetrahydrophthalic anhydride mixture, according to The ratio of 100 parts: 95 parts was stirred and mixed at 130°C, fully dissolved to obtain a homogeneous solution; the temperature was lowered to 80°C to obtain prepolymer A, and set aside;

[0034] (2) Mix polysulfone ester and acid anhydride curing agent methyl hexahydrophthalic anhydride (MHHPA) according to the ratio of 21.5 parts: 85 parts, and stir at 120-150°C for 1 hour, so that polysulfone ester is fully dissolved in methyl hexahydrophthalic anhydride , then add 0.5 parts of cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com