Coating composition for enhancing light transmittance and coating layer formed therefrom

A composition and coating technology, applied in the directions of coatings, optics, optical components, etc., can solve the problems of unfavorable production and high manufacturing costs, and achieve the effects of cost saving, simple manufacturing process, and simplified preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0058] The siloxane monomer / oligomer, the first SiO 2 The particle aqueous solution and the solvent were pre-mixed and stirred according to the ratio (gram weight) shown in Table 1, heated to 75±2°C with nitrogen gas and reacted for 6 hours to prepare compositions a to e.

[0059] Table 1

[0060]

[0061]

[0062] Note 1 Total solid content: that is, the ratio (weight ratio) of all solid content to the composition. For example, take the composition and weigh it, and record its actual weight as a (total weight), heat it to remove the solvent (for example, for 1 gram of the composition, heat it on a heating plate at 150°C for 30 minutes) and then weigh it again The weight is b (total weight of solid parts), and b / a is the total solid content (%).

[0063] Note 2 SiO 2 / Total solid content: namely SiO 2 The ratio of solid content to total solid content (%), taking composition a as an example, the first SiO 2 The weight of solids in the particle aqueous solution is 178...

Embodiment 1

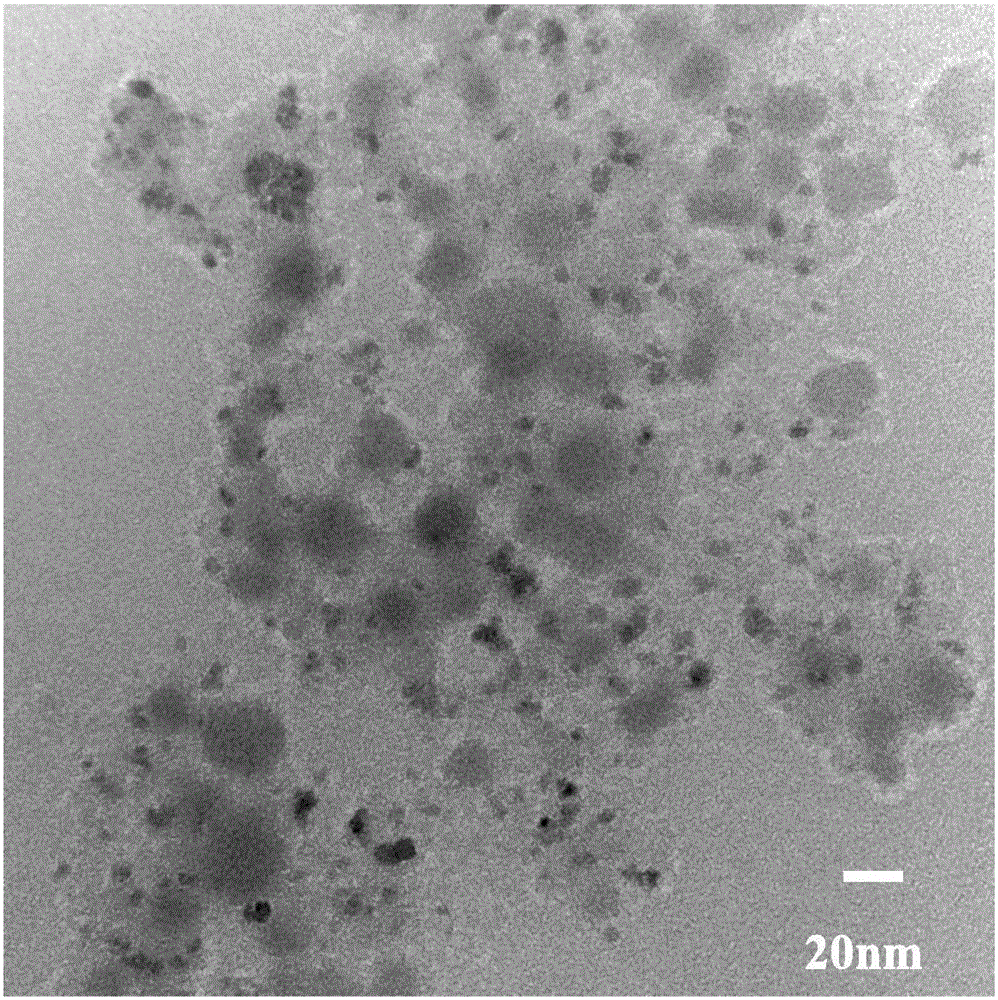

[0101] The first SiO in embodiment 1, 8 and 9 2 particles with the second SiO 2 The particle ratio is similar (11.4~11.5), and Example 1 does not contain TiO 2 Particles, Example 8 and 9 add TiO 2 (Particle size less than 70nm). The penetrations obtained in Examples 1, 8 and 9 are 108.6%, 107.4% and 106.6% respectively.

Embodiment 10

[0102] The composition and ratio of Example 10 and Comparative Example 14 are similar, however, Comparative Example 14 uses TiO with a particle size greater than 70nm 2 particle. The penetrations obtained in Example 10 and Comparative Example 14 were 103.3% and 100.2%, respectively. It can be seen that TiO 2 Too many particles will affect the effect of light penetration.

[0103] As can be seen from the aforementioned results, the present invention can be added with or without adding TiO 2 Particle implementation. Use TiO 2 Although the particles will affect the light penetration effect, but the control of TiO 2 The particle size of the particles in the appropriate range (less than 70nm) can still achieve the effect of increasing light penetration and can be used by TiO 2 The particles provide self-cleaning properties.

[0104] TiO 2 Effect of particle addition on coating properties:

[0105] The composition and proportion of embodiment 10 and comparative example 13 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com