An energy-saving utilization system of delayed coking unit

A delayed coking and venting tower technology, applied in the field of energy utilization, can solve the problems of low attention, large water consumption, and poor utilization of heat energy, etc., and achieve the effects of reliable technology, high energy consumption, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The energy-saving utilization system of the delayed coking unit of the present invention, its preferred specific embodiment is:

[0019] Including a vent tower, a steam generator is arranged at the bottom of the vent tower, a heat exchange tube is arranged in the steam generator, and the bottom oil of the vent tower is connected to the heat exchange tube through a bottom pump, The casing of the steam generator is provided with a medium water inlet and a steam outlet.

[0020] The steam outlet is connected to the steam pipe network of the whole plant.

[0021] The medium water is deoxygenated water.

[0022] The liquid level is controlled by three parameters: dual liquid level ratio selection, steam flow rate and feed water flow rate.

[0023] The energy-saving utilization system of the delayed coking unit of the present invention solves the problem of high energy consumption of the vent tower system in the existing device, and at the same time by-produces high value-a...

specific Embodiment

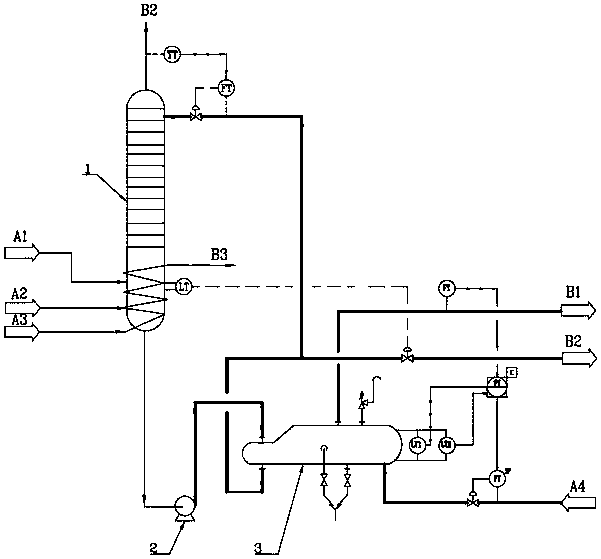

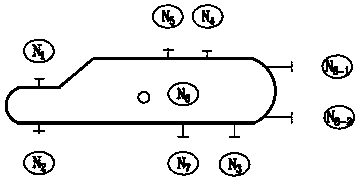

[0027] Such as figure 1 , figure 2 As shown, in a delayed coking production unit, the bottom oil of the vent tower is discharged from the bottom pump 2 of the vent tower, and enters the steam generator at the bottom of the vent tower through the N1 nozzle, and the deoxygenated water enters the steam generator from the N3 nozzle at the bottom of the shell side After heat exchange between the two, the cooled bottom oil of the vent tower comes out through the N2 nozzle and is divided into two parts: one part is returned to the top of the vent tower 1 as reflux, and the oil and gas in the cooling tower are recovered to the maximum extent. The oil in it; part of it is out of bounds as the bottom product. The deoxygenated water absorbs a large amount of heat and is gasified to generate 1.0MPa saturated steam, which exits the steam generator through the N4 nozzle and enters the steam pipe network of the whole plant for use by equipment and users.

[0028] The steam generator is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com