Sn-containing ferrite stainless steel with low cost and high corrosion resistance, and manufacturing method thereof

A manufacturing method and high corrosion resistance technology, applied in the field of ferritic stainless steel and its manufacturing, can solve the problems of not meeting the low-cost design requirements, not meeting the ferritic stainless steel, and not having relevant research on corrosion resistance, and achieving improvement Effect of surface quality, alloy cost reduction, and SOX corrosion resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

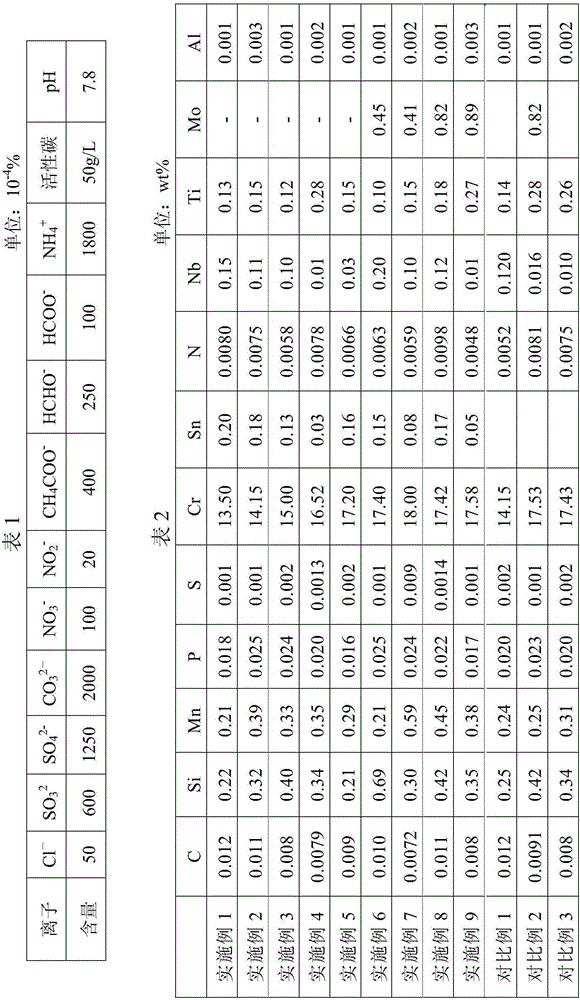

Method used

Image

Examples

Embodiment 1

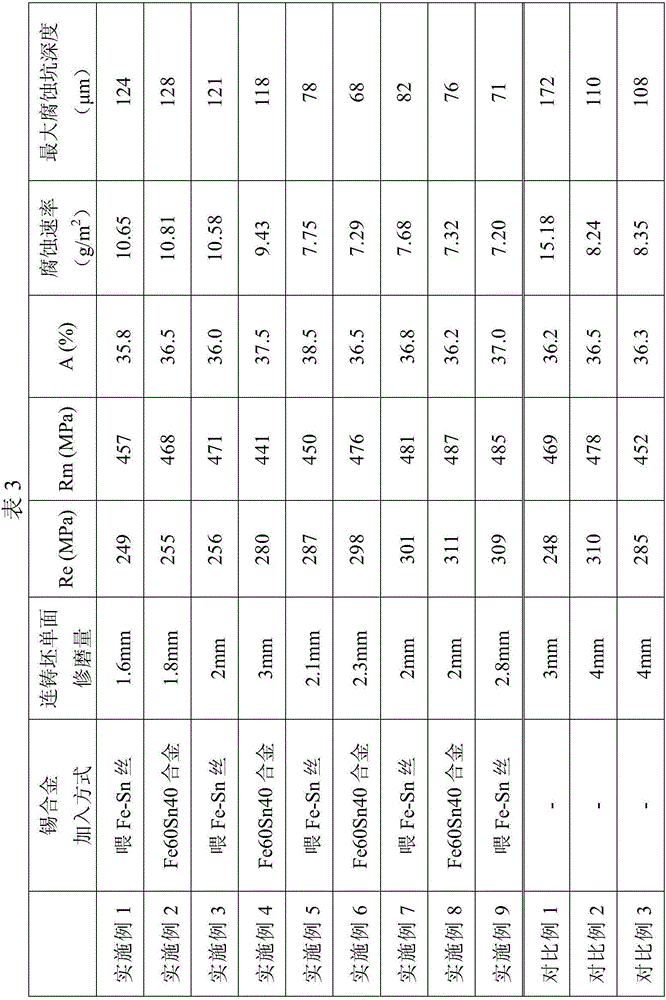

[0046] Examples 1-3 are 13.5-15wt% Cr stainless steel containing Sn, and Comparative Example 1 does not carry out Sn microalloying 14Crwt%. It can be seen from the comparison that Sn microalloying has obvious improvement on corrosion resistance, and the corrosion rate From 15.18g / m in comparative example 1 2 Reduced to 10.65g / m in Example 1 2 , the corrosion rate is reduced by about 40%; the maximum corrosion pit depth is reduced from 172 μm in Comparative Example 1 to about 124 μm in Example 1, and the corrosion pit depth is reduced by about 38%, while the mechanical properties remain basically unchanged.

[0047] Examples 1-3 are 13.5-15wt% Cr stainless steel containing Sn, and comparative examples 2 and 3 are 17wt% Cr stainless steel without Sn microalloying. It can be seen from the comparison that the 13.5-15wt% Cr stainless steel containing Sn is corrosion-resistant The properties are close to or reach 17wt% Cr ferritic stainless steel, where the corrosion rate is from 1...

Embodiment 3

[0049] Embodiment 3 is the stainless steel of low Ti, is the stainless steel contrast of high Ti with embodiment 4; Embodiment 8 is the stainless steel of low Ti, is the stainless steel contrast of high Ti with embodiment 9; Embodiment 3,4 corrosion resistance is quite, The corrosion resistance of Examples 8 and 9 is equivalent, wherein the single-side grinding amount of continuous casting slabs in Examples 3 and 8 is about 2 mm, while the single-side grinding amount of continuous casting slabs in Examples 4 and 9 is about 3 mm; Compared with ratios 2 and 3, the corrosion resistance is equivalent. Among them, embodiment 3 is a Sn-containing stainless steel, which reduces the content of Ti, and the single-side grinding amount of the continuous casting slab is about 2mm. The amount of grinding is about 4mm, which can reduce the amount of grinding on the surface of the continuous casting slab during the manufacturing process.

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com