Manufacture process of polyester/bast fiber elastic cushion

A polyester fiber and manufacturing process technology, applied in the field of fiber mats, can solve the problems of excessive formaldehyde volatilization, uneven support force, loud sound, etc., and achieve the effect of quiet use environment and uniform support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

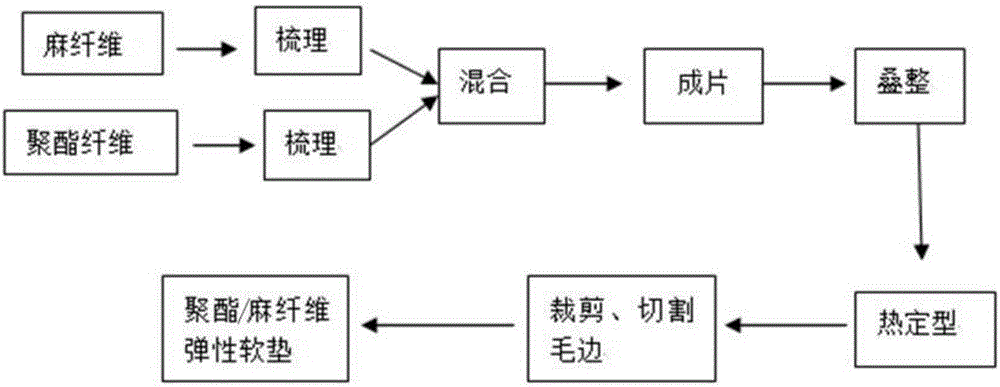

[0019] Such as figure 1 Shown, a kind of manufacturing process of polyester / hemp fiber elastic soft cushion comprises the following steps:

[0020] (1) Opening and carding: Unpack the hemp fiber and polyester fiber raw materials, respectively perform opening and carding on the fiber opening and carding machine, loosen the compressed and entangled raw materials and remove impurities, and fully card them into single fiber state;

[0021] (2) Mixing: according to the design of the cushion, the ingredients are put into the fiber mixer for full mixing, wherein the input weight ratio of hemp fiber and polyester fiber is 1:1;

[0022] (3) sheeting: the mixture of hemp fiber and polyester fiber is spread into a sheet layer, and the thickness of the sheet layer is 2cm;

[0023] (4) Stacking: stacking multiple layers of fiber sheets to 30cm;

[0024] (5) Heat setting: put the stacked fiber layers into the bellows, first pass the hot air flow prepared by electric heating into the bell...

Embodiment 2

[0027] A kind of manufacture technology of polyester / hemp fiber elastic cushion, comprises the following steps:

[0028] (1) Opening and carding: Unpack the jute fiber and polyester fiber raw materials, respectively perform opening and carding on the fiber opening and carding machine, loosen the compressed and entangled raw materials and remove impurities, and fully card them into single fiber state;

[0029] (2) Mixing: carry out batching according to cushion design, put into fiber mixer and fully mix, wherein the input weight ratio of jute fiber and polyester fiber is 1:1;

[0030] (3) into sheet: the jute fiber and polyester fiber mixture are spread into sheet layer, and sheet layer thickness is 2cm;

[0031] (4) Stacking: stacking multiple layers of fiber sheets to 40cm;

[0032] (5) Heat setting: put the stacked fiber layers into the bellows, first pass hot air into the bellows to keep the temperature in the bellows at 200°C, so that the polyester fibers in the fiber la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com