Food wrapping paper and production method thereof

A technology for food wrapping paper and production method, which is applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of poor antibacterial and oil-repellent properties, insufficient gloss of paper, etc., and achieve the effect of increasing gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

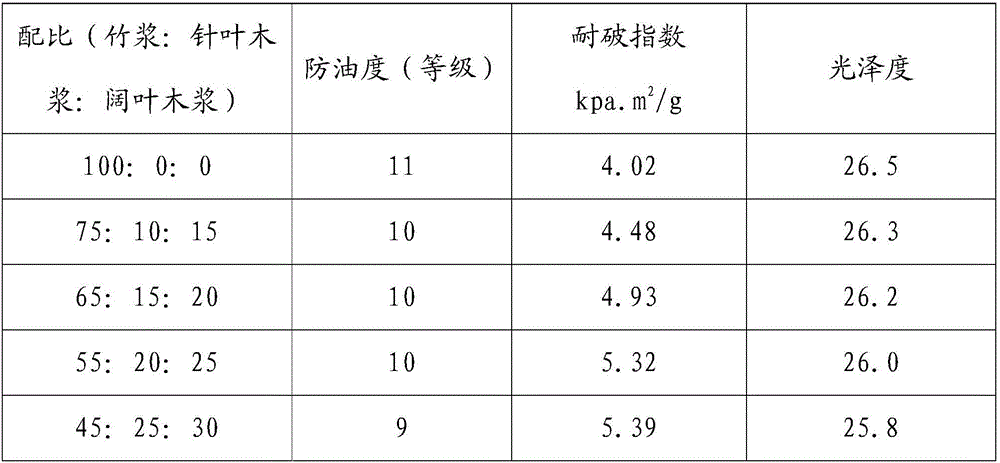

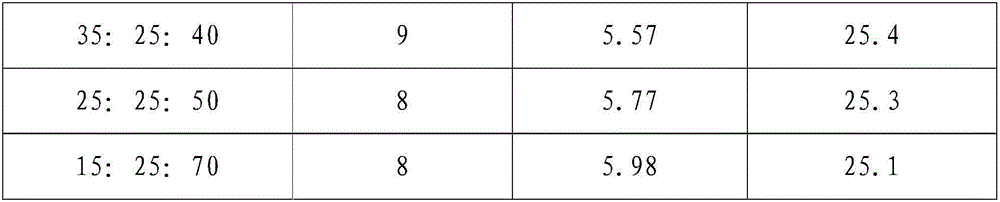

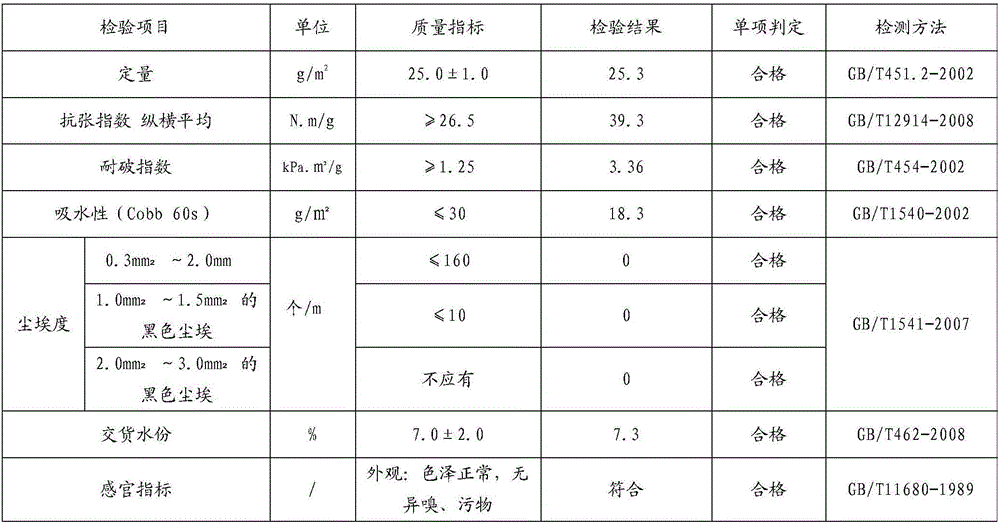

Examples

Embodiment 1

[0036] A production method of food packaging paper, comprising the following steps:

[0037] Step 1: beating coniferous wood pulp, broad-leaved wood pulp and bamboo pulp respectively, controlling the temperature of the slurry during beating at 38-45°C; the beating concentration of the coniferous wood pulp: 4.0%, and the degree of beating is 65-70 degrees The beating concentration of the hardwood pulp is 4.0%, and the beating degree is 50-55 degrees; the beating concentration of the bamboo pulp is 4.5%, and the beating degree is 60-65 degrees; when bamboo pulp or coniferous wood pulp is beaten , adding complex cellulose beating enzyme RH-2 in the slurry, the enzyme activity of the complex cellulose beating enzyme RH-2 is 4800u / g, and the consumption of the complex cellulose beating enzyme RH-2 is equivalent to that of the slurry 0.001-0.0015% of;

[0038] Step 2: mixing 20-25 parts of softwood pulp, 65-70 parts of hardwood pulp and 10-15 parts of bamboo pulp in a mixing tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com