Snap-in two-stage friction energy dissipation damper

A technology of friction energy consumption and damper, which is applied in protective buildings/shelters, building components, shockproof, etc., can solve the problems of low efficiency and achieve the effect of easy replacement, simple component structure and increased friction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

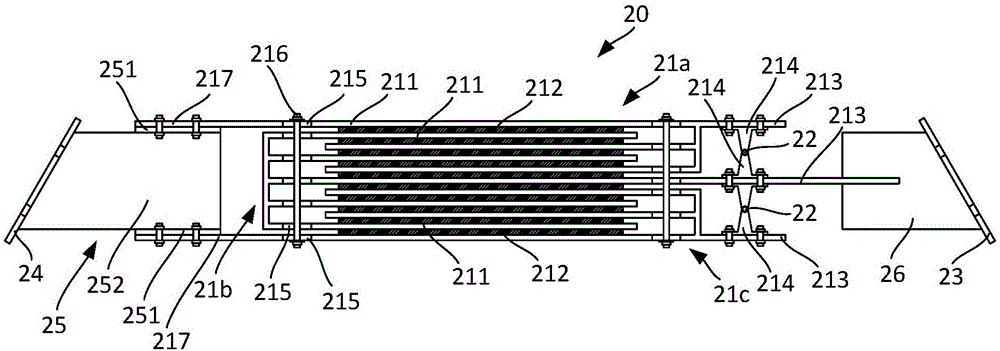

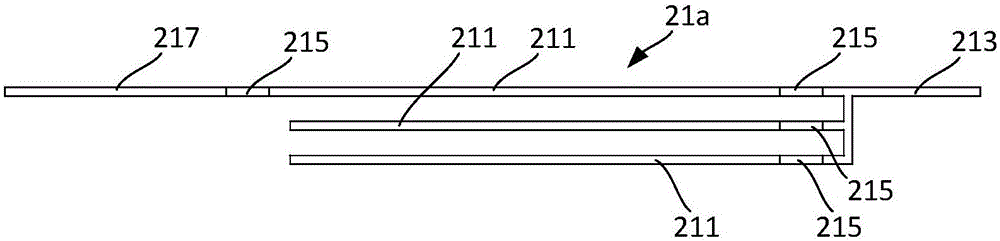

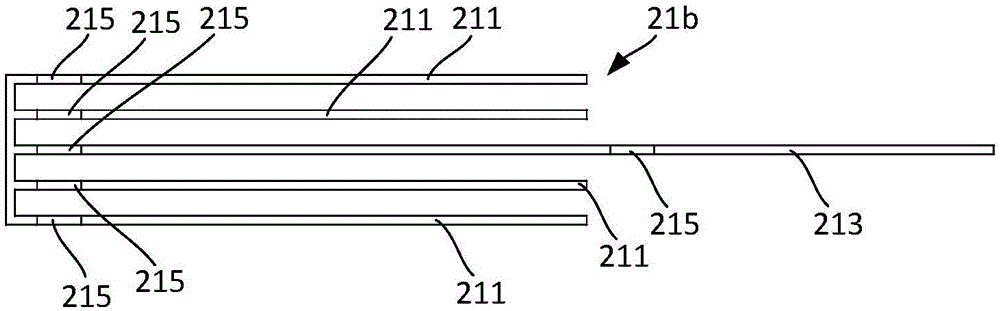

[0033] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0034] The invention provides a snap-type two-stage friction energy dissipation damper, which is applied to middle and high-rise buildings, high-rise buildings, and large-span spatial structures, and can also be applied to the reinforcement and transformation of existing buildings. The damper can not only provide rigidity for the building structure under the action of small earthquakes and wind vibration, but also provide friction energy consumption for the building structure under the action of moderate and large earthquakes, which has a good energy consumption effect and solves the existing problems. The problem of low efficiency of friction dampers under small earthquakes and wind vibrations. The damper of the present invention is connected with a shear pin between the sliding components, and the setting direction of the shear pin is perpendicular to the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com