Energy-saving automobile engine cooling water pump

A technology of automobile engine and cooling water pump, which is applied in the direction of engine cooling, engine components, machines/engines, etc., which can solve the problems of large power loss, low work efficiency, and loud noise, and achieve improved efficiency, compact structure, and reduced water flow noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

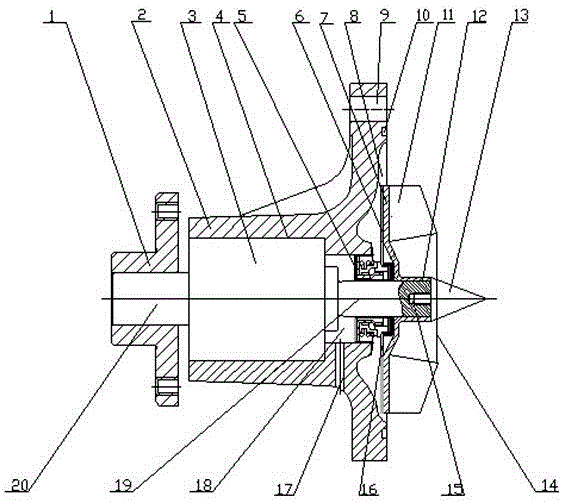

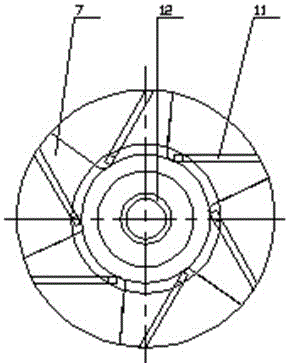

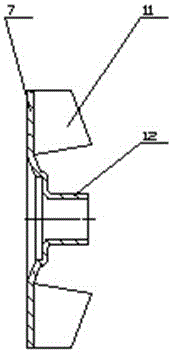

[0019] Embodiment: (see for details figure 1 ) An energy-saving automobile engine cooling water pump, which has a pump casing 2, and the pump casing 2 is respectively provided with a bearing position 4, a water seal position 18, a spiral flow channel 8, a water leakage hole 17, a machine hole 9, and a sealing groove 10; A shaft-connected bearing 3 is installed at the bearing position 4 of the shell 2, and the left end journal 20 of the shaft-connected bearing 3 is installed with a transmission flange 1, the middle part of the right-end journal 19 of the shaft-connected bearing 3 and the water seal position 18 of the pump casing 2 A water seal 5 is installed at the place, and the end surface of the right-end journal 19 of the shaft-connected bearing 3 is provided with a screw hole 15, and the right-end journal 19 is equipped with an impeller 12, and the impeller 12 is an open impeller formed by stamping a steel plate. The blade 11 is on the side of the water inlet 14 of the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com