Running method of heat pump unit of energy-self-supplied gas engine

An operation method and gas engine technology, applied in the direction of machine operation, energy industry, heating and refrigeration combination, etc., can solve problems such as unfavorable popularization and application of gas engine heat pumps, improve practicability and adaptability, and overcome high initial investment 、To overcome the effect of long laying period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

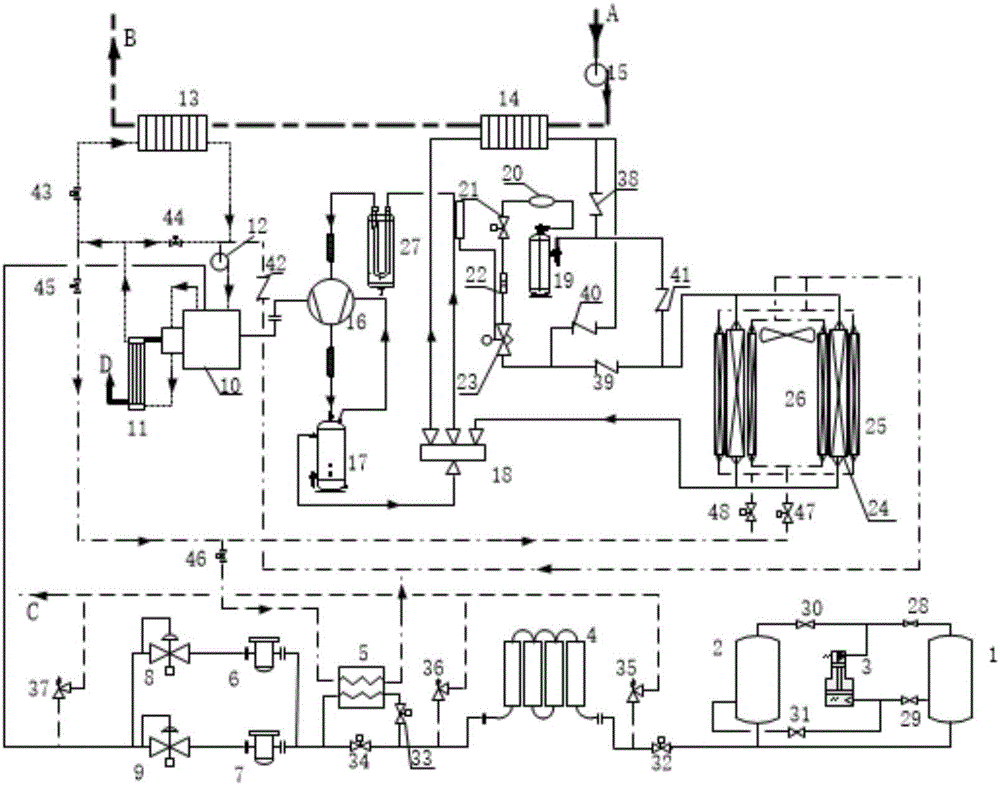

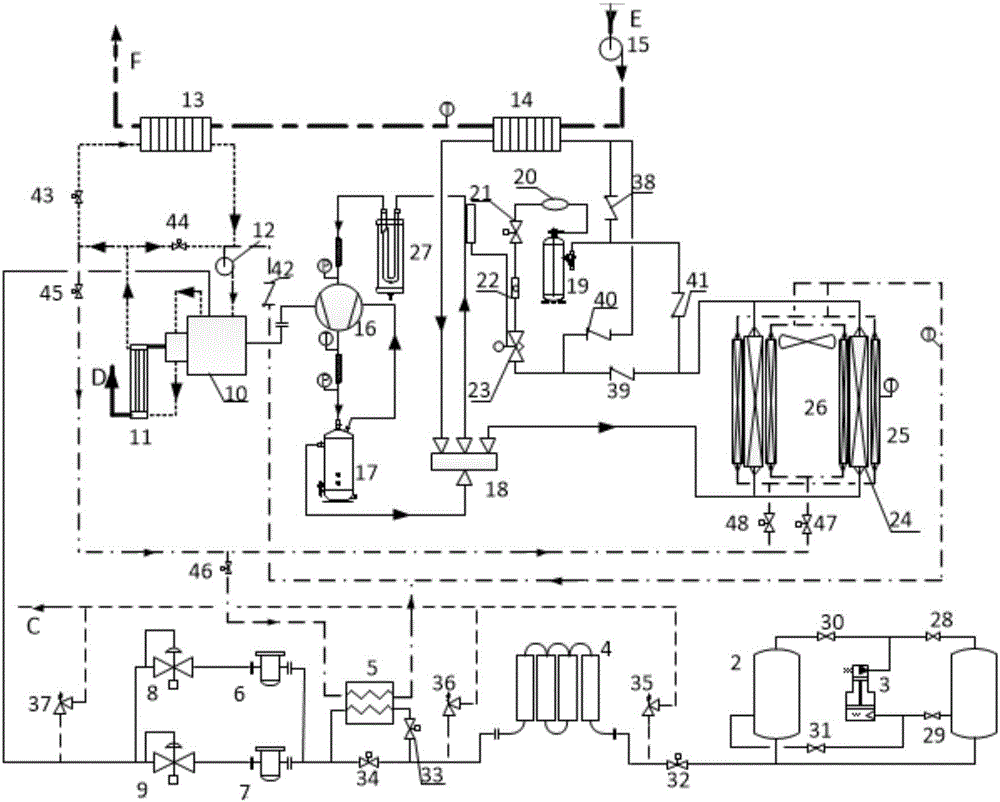

Image

Examples

Embodiment 1

[0059] Heating mode operation:

[0060] The heating mode operation process includes a heating cycle, a waste heat recovery cycle and a user hot water supply cycle. The steps of the heating cycle are as follows:

[0061] (a) When the internal pressure of each gas storage cylinder 1 and 2 in the liquefied natural gas (LNG) gas storage cylinder group is higher than the set pressure of 0.3MPa, the liquefied natural gas flows out directly through the liquid phase port of each gas storage cylinder under the action of pressure ; When the internal pressure of each gas cylinder 1 and 2 in the liquefied natural gas cylinder group is lower than the set pressure of 0.3 MPa, the self-pressurized vaporizer 3 is opened, and the liquefied natural gas in each gas cylinder 1 and 2 The liquid phase ports of the gas storage cylinders flow out through the outlet gate valves and then flow back into the gas storage cylinders 1 and 2, so that the pressure in the gas storage cylinders increases, and t...

Embodiment 2

[0071] Heating mode operation:

[0072] The heating mode operation process includes a heating cycle, a waste heat recovery cycle and a user hot water supply cycle. The steps of the heating cycle are as follows:

[0073] (a) When the internal pressure of each gas storage cylinder 1 and 2 in the liquefied natural gas (LNG) gas storage cylinder group is higher than the set pressure of 0.35MPa, the liquefied natural gas flows out directly through the liquid phase port of each gas storage cylinder under the action of pressure ; When the internal pressure of each gas cylinder 1 and 2 in the liquefied natural gas cylinder group is lower than the set pressure of 0.35MPa, the self-pressurized vaporizer 3 is opened, and the liquefied natural gas in each gas cylinder 1 and 2 The liquid phase ports of the gas storage cylinders flow out through the outlet gate valves and then flow back into the gas storage cylinders 1 and 2, so that the pressure in the gas storage cylinders increases, and ...

Embodiment 3

[0083] Heating mode operation:

[0084] The heating mode operation process includes a heating cycle, a waste heat recovery cycle and a user hot water supply cycle. The steps of the heating cycle are as follows:

[0085] (a) When the internal pressure of each gas storage cylinder 1 and 2 in the liquefied natural gas (LNG) gas storage cylinder group is higher than the set pressure of 0.35MPa, the liquefied natural gas flows out directly through the liquid phase port of each gas storage cylinder under the action of pressure ; When the internal pressure of each gas cylinder 1 and 2 in the liquefied natural gas cylinder group is lower than the set pressure of 0.35MPa, the self-pressurized vaporizer 3 is opened, and the liquefied natural gas in each gas cylinder 1 and 2 The liquid phase ports of the gas storage cylinders flow out through the outlet gate valves and then flow back into the gas storage cylinders 1 and 2, so that the pressure in the gas storage cylinders increases, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com