Vibration tank fall type bagasse smoke drying device

A technology of bagasse and vibration tank, which is applied in the direction of drying gas arrangement, biomass drying, drying solid materials, etc., can solve the problems of unfavorable bagasse full utilization and low calorific value, so as to achieve good equipment operation effect, reduce moisture content, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

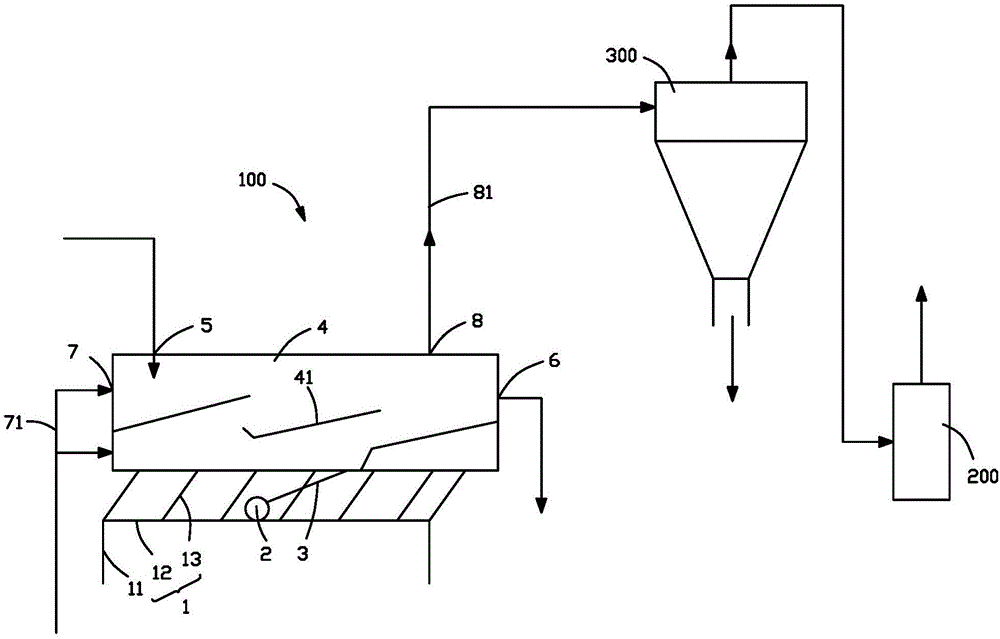

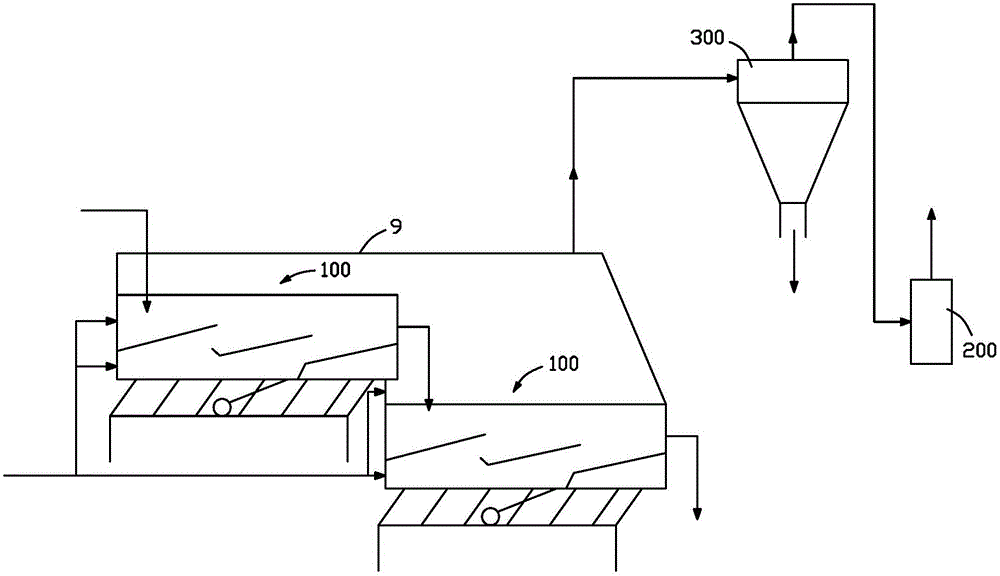

[0027] see figure 1 , in a preferred embodiment of the present invention, a vibration tank 4 drop-type flue gas drying bagasse device includes a drying assembly 100, and the drying assembly 100 includes a vibration plate 1, a motor 2, and a rocker arm 3 And a vibration tank 4, the motor 2 is installed on the vibration plate 1, and its output shaft is vertically connected to the rocker arm 3, and drives the rocker arm 3 to swing back and forth; the vibration tank 4 is located above the vibration plate 1, and is connected to the motor 2 through the rocker arm 3, And can swing back and forth with the rocker arm 3; There are at least two stages of object-bearing plates 41 in the vibration tank 4, and the object-bearing plates 41 are arranged along a direction in which the vibration tank 4 swings, and are inclined, and the lower side is the inlet end , the higher side is the outlet end, and the outlet end of the upper-level object-bearing plate 41 is located above the inlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com