Disposable spherical gas blaster of composite structure and manufacturing method of disposable spherical gas blaster

A composite structure, one-time technology, applied in chemical instruments and methods, blasting cylinders, earthwork drilling and mining, etc., can solve problems such as low yield, time-consuming inflation process, and small gas storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

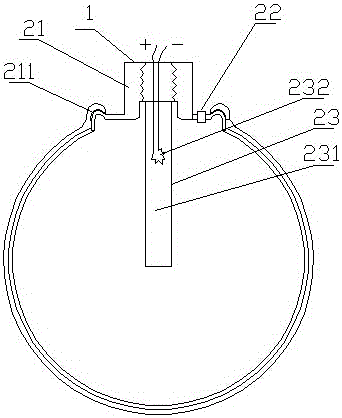

[0104] Example 1 (eg figure 1 As shown), a carbon dioxide blaster includes an energy storage device 1 and an inflatable detonator 2, the energy storage device 1 is equipped with an inflatable detonator 2; the energy storage device 1 is made of a material with a compressive strength greater than 345Mpa, and the energy storage The device 1 has a spherical structure, and the inflation mechanism 22 adopts a one-way valve inflation structure.

[0105] As a further specific description of the above implementation, the energy storage device 1 is formed by solidifying any one or at least two of carbon fibers, glass fibers, aramid fibers, polyester fibers or composite materials thereof.

[0106] As a further specific description of the above implementation, the energy storage device 1 has a two-layer structure, and the energy storage device 1 includes a mesh layer 12 and a hardened layer 13 distributed from the inside to the outside.

[0107] As a further specific description of the ...

Embodiment 2

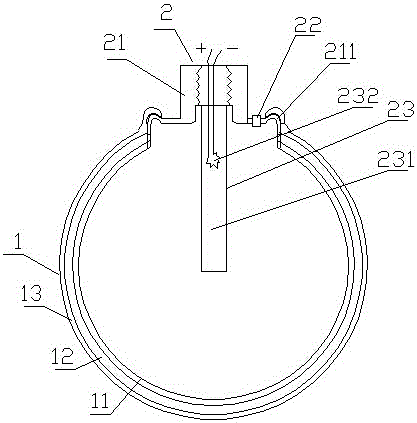

[0121] Embodiment two: the difference with embodiment one is: (such as figure 2 As shown) the energy storage device (1) has a three-layer structure, from the inside to the outside is the base layer (11), the mesh layer (12) and the hardened layer (13); the mesh layer (12) is carbon fiber , glass fiber, aramid fiber, polyester fiber or composite materials thereof, the hardened layer (13) is made of epoxy resin glue material, and the base layer (11) is made of polyethylene material.

Embodiment 3

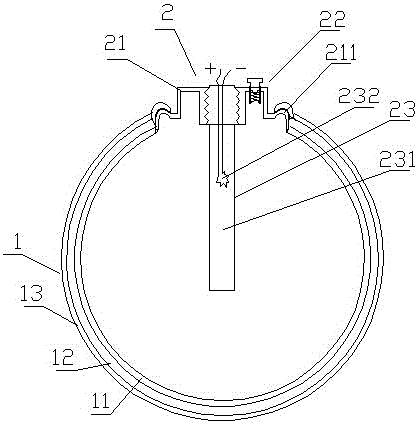

[0122] Embodiment three: the difference with embodiment two is: (such as image 3 As shown), the threaded structure in the middle of the sealing base 21 is inwardly recessed; this structure is convenient for transportation and saves the overall volume, and at the same time, it is convenient for protecting the inflatable detonator 2 from being hit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com