Special verification/calibration device for digital level

A technology of digital leveling and calibration device, applied in measurement devices, instruments, etc., can solve the problems of inaccurate measurement, inability to measure, and impossible to scribe barcode images at the same time, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

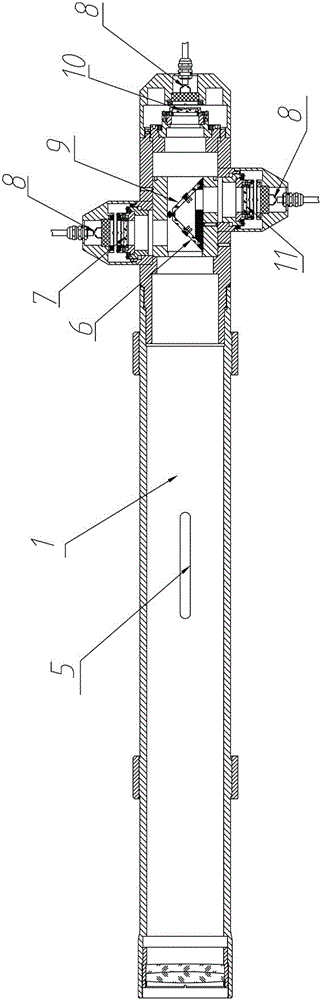

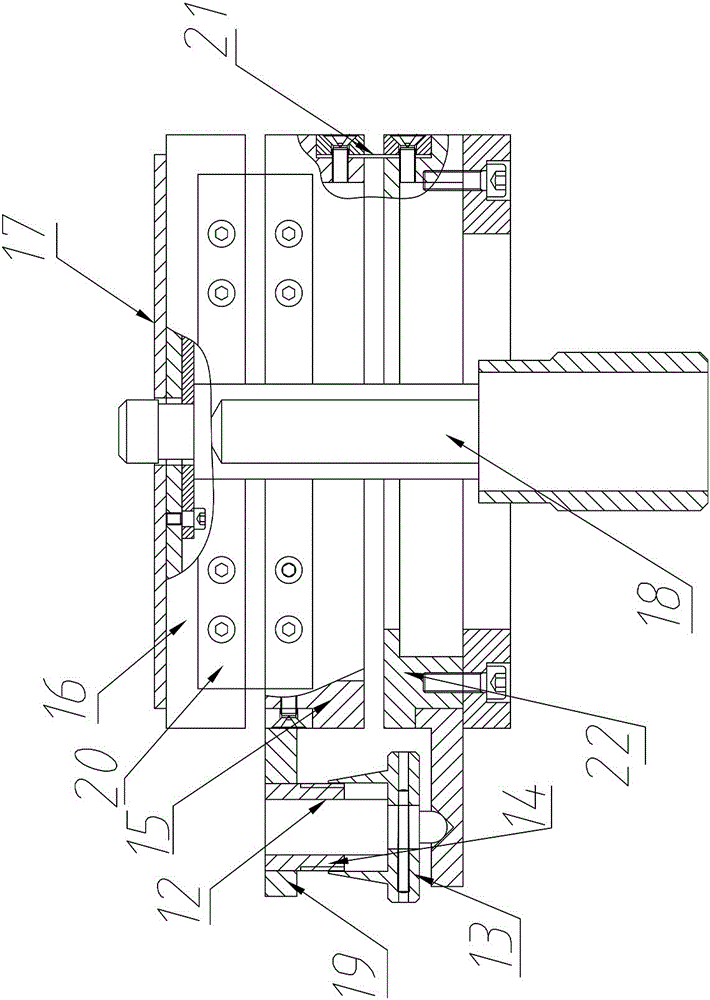

[0024] The special verification / calibration device for the digital level of the present invention comprises two collimator tubes 1 opposite to each other; the central axes of the two collimator tubes 1 are on the same straight line, and three reticles are arranged on the collimator tube 1 Mounting heads, wherein two reticle mounting heads are arranged on the tube body of the collimator 1, and the other reticle mounting head is arranged on one end of the collimator 1, the central axes of the reticle mounting heads are at the same In the horizontal plane; the reticle installation head is fixedly equipped with a reticle and a light source 8;

[0025] A beam splitter is respectively arranged in an opening end of the two reticle mounting heads installed on the body of the collimator 1, and the opening ends are all located in the collimator 1, and the beam splitters are the first beam splitter 6 and the first beam splitter respectively. The second beam splitter 9, and the normal lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com