Electric-conductive liquid level sensor applied to severe environments

A harsh environment, conductance technology, applied in the direction of liquid level indicators for physical variable measurement, etc., can solve the problems that the application problems of conductance liquid level sensors have not been well resolved, and achieve a solid mechanical design structure, high sensitivity, and avoid The effect of metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

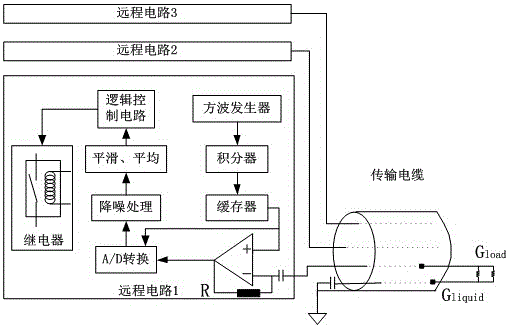

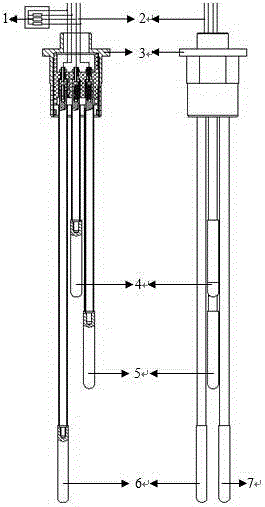

[0019] A conductivity type liquid level sensor used in harsh environments includes a sensing probe consisting of one or more probes, a transmission cable connected to a remote circuit, and the remote circuit.

[0020] A conductive liquid level sensor used in harsh environments, its overall structure is as follows figure 1 As shown, the triangular wave generated by the circuit is used as the positive input of the operational amplifier, and through the negative feedback resistor R, the triangular wave is also used as the negative input of the operational amplifier. The remote circuit is connected to the sensing probe through a transmission cable. In harsh environments such as high temperature, high humidity, or corrosive ions, the sensing probe may generate a DC voltage due to heat and electrochemistry. The capacitance between the operational amplifier and the remote cable is used to prevent the induced charge flow or heat and electrochemical The associated corrosion produced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com