Automatic cold plate flow resistance testing system

A test system and cold plate technology, applied in fluid dynamics test, machine/structural component test, measuring device, etc., can solve the problems of low test efficiency, cumbersome and complicated cold plate process, low degree of automation, etc., and achieve test speed Fast, improve test efficiency, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

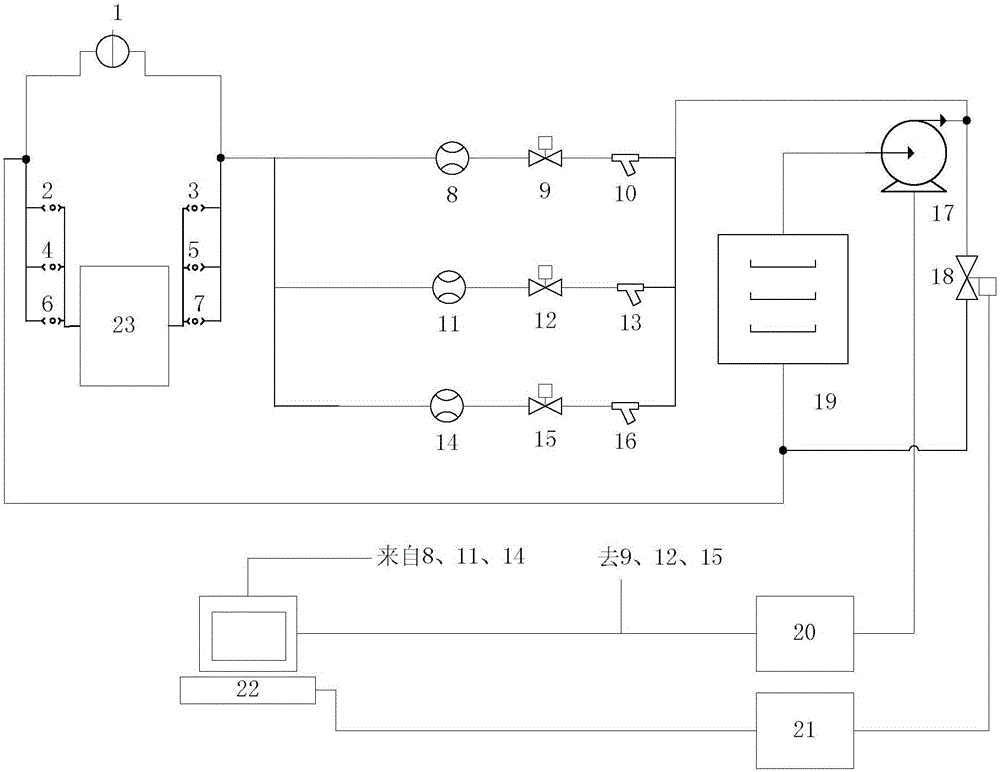

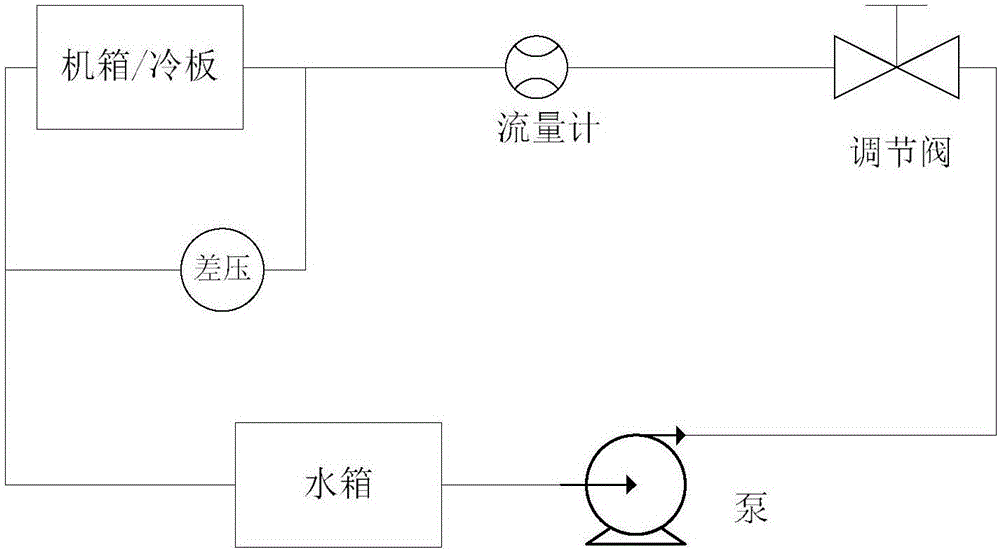

[0027] refer to figure 1 . In the embodiment described below, a cold plate flow resistance test system includes a double-connected differential pressure sensor 1 with a line array at both ends and a quick connector group to form a double-circuit assembly of the cold plate circulation circuit to be tested, three sets The flow meter, the shut-off valve and the filter are connected in series to form a three-loop environment-controlled liquid-separation parallel flow path and a cold liquid circulation loop composed of a circulation pump 17 in parallel with a bypass regulating valve 18 and a liquid return storage tank 19. Among them, the three-loop The environmental control liquid separation parallel flow path is connected in series between the cold plate circulation circuit to be tested and the cold liquid circulation circuit in the double circuit assembly, and the differential pressure sensor 1 is connected to the common terminal point of the return liquid storage tank 19 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com