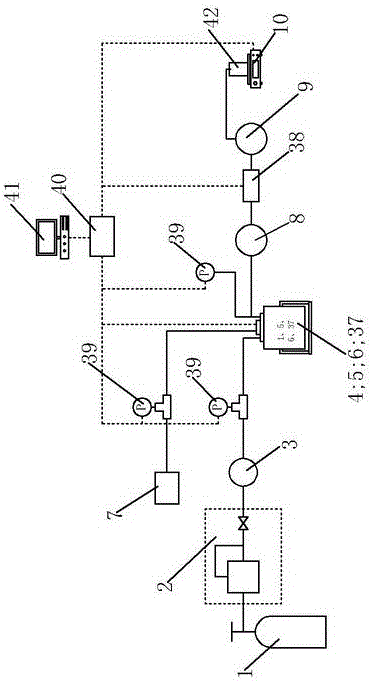

Device for testing permeability under high temperature and high pressure

A high temperature and high pressure, test device technology, used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

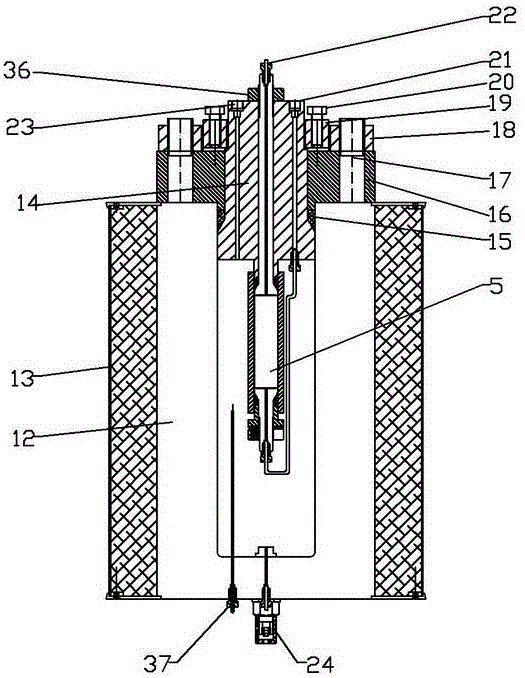

Embodiment 1

[0037] Embodiment 1: using near-critical water as permeate fluid:

[0038] 1. Rock sample preparation

[0039] (1) Drilling and cutting the rock sample, washing the rock sample with oil, drying, and measuring the geometric size of the rock sample. For the operation method, refer to steps A to C of step 1 in the specific implementation mode.

[0040] (2) Wrap the core: Cut the heat-shrinkable tube and wrap the core with expanded polytetrafluoroethylene tape to ensure the integrity of the sample. When wrapping, the thickness of each part should be uniform to ensure that it can bear the confining pressure evenly.

[0041] 2. Make sure that the liquid in the oil storage container and various pumps is sufficient.

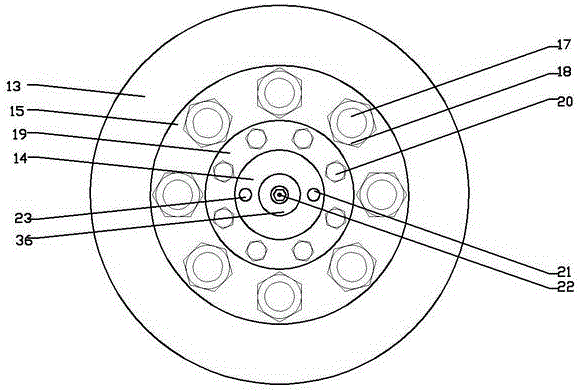

[0042] 3. Assemble the high-temperature and high-pressure core holder (5). For this step, refer to step 3 in the specific implementation method.

[0043] 4. Install the high temperature and high pressure core holder (5). For this step, refer to step 5 in the specific ...

Embodiment 2

[0052] Embodiment 2: Using high-temperature nitrogen as the permeating fluid:

[0053] 1. Rock sample preparation

[0054] (1) Drilling and cutting rock samples, oil washing of rock samples, drying, and measuring the geometric dimensions of rock samples: for the specific operation method, refer to steps A to C of step 1 in the specific implementation mode.

[0055] (2) Since 400°C high-temperature nitrogen was used as the permeating fluid this time, the temperature has exceeded 370°C (the melting point of polytetrafluoroethylene material), so the core was not wrapped in this test.

[0056] 2. Make sure that the liquid in the oil storage container and various pumps is sufficient.

[0057] 3. Assemble the high-temperature and high-pressure core holder (5). For this step, refer to step 3 in the specific implementation method.

[0058] 4. Install the high temperature and high pressure core holder (5). For this step, refer to step 5 in the specific implementation mode.

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com