Dual-zone fuel coolant counterflow fuel assembly and supercritical water cooled reactor

A technology of fuel assembly and reverse flow, which is applied in the direction of reactor fuel elements, assembly of fuel elements, reactors, etc., can solve problems such as economical decline, reduce structural materials, improve neutron economics and engineering realizability, The effect of improving engineering realizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

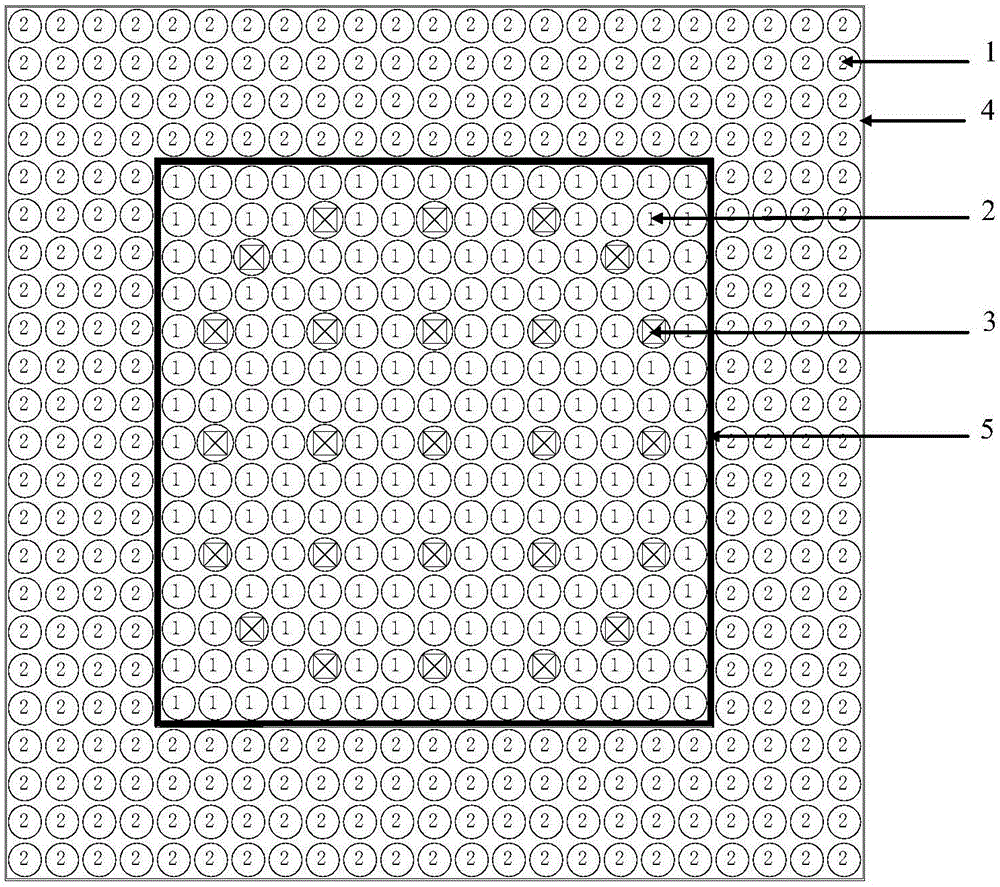

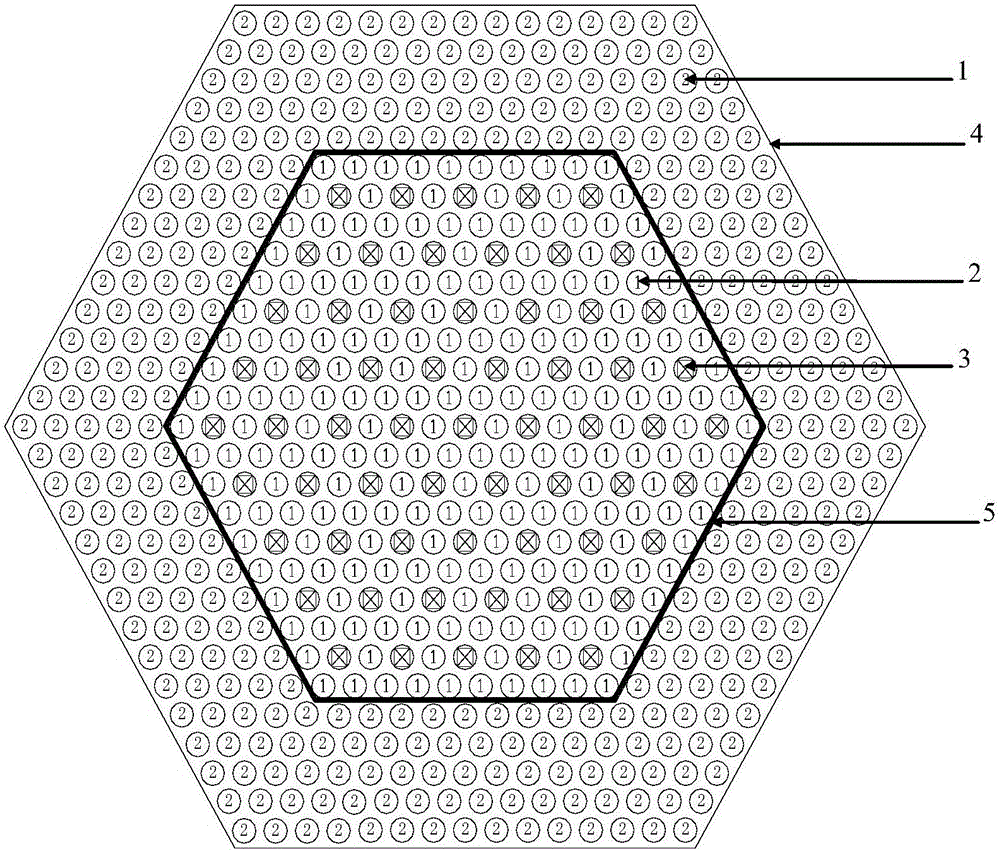

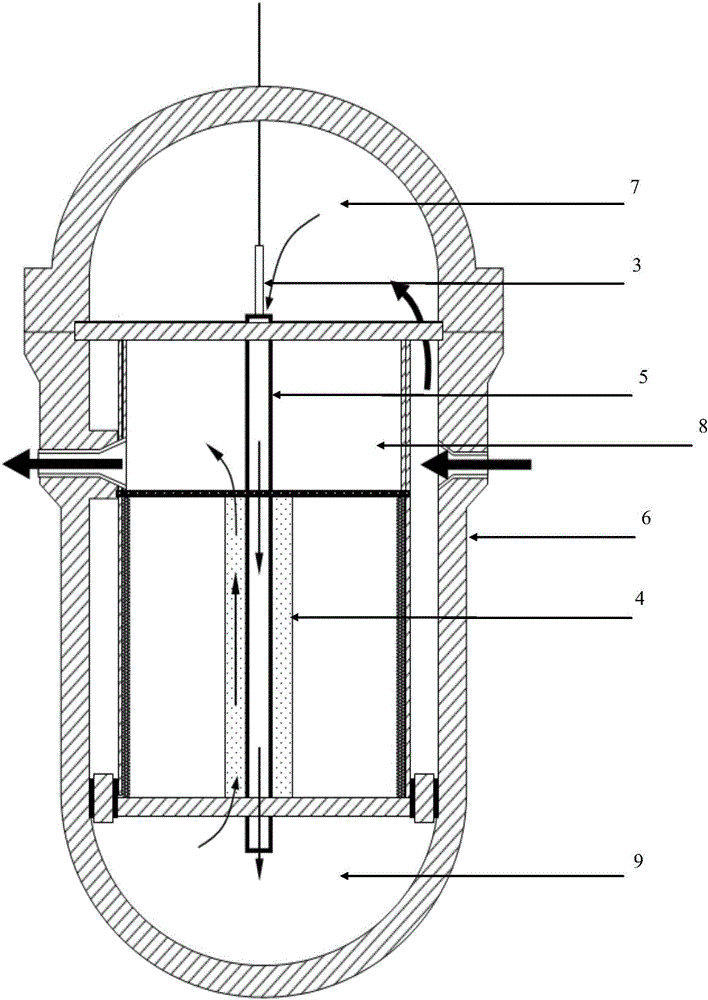

[0029] like Figure 1 to Figure 3 As shown, a dual-zone fuel coolant reverse-flow fuel assembly includes a fuel assembly body, and the fuel assembly body includes a cylindrical thermal insulation shroud 5 and a component box 4. The component box 4 is sleeved on Outside the heat insulating shroud 5, the inner region fuel rods 2 and the guide tubes 3 are arranged in the insulating shroud 5, and the outer region fuel rods are arranged between the outer wall of the insulating shroud 5 and the inner wall of the component box 4 1, and there are more than one inner fuel rod 2, guide tube 3, and outer fuel rod 1. The inner fuel rod 2 and the adjacent guide tube 3 or the inner fuel rod 2, the outer fuel rod 1 and the The adjacent outer fuel rods 1 are distributed at intervals.

[0030] In this embodiment, in the above fuel rod body structure, a plurality of fuel assemblies are divided into an inner area and an outer area by using a heat insulating shroud 5, and a guide tube 3 is provi...

Embodiment 2

[0035] This embodiment further defines or provides specific implementations on the basis of the fuel assembly provided in Embodiment 1, such as Figure 1 to Figure 3 As mentioned above, the inner area fuel rods 2 and the guide tubes 3 in the heat insulating enclosure 5 are arranged in a square or hexagonal grid, and the outer area fuel rods 1 between the outer wall of the insulating enclosure 5 and the inner wall of the component box 4 Arranged in a square or hexagonal grid relative to each other.

[0036] The inner fuel rod 2 is a low enrichment UO 2 Fuel, the outer fuel rod 1 is high enrichment UO 2 fuel or MOX fuel, the low enrichment UO 2 fuel for 235 UO with U enrichment less than 5% 2 fuel, the high enrichment UO 2 fuel for 235 UO with U enrichment greater than or equal to 5% 2 fuel.

[0037] The rod diameter of the fuel rods 2 in the inner region is smaller than or equal to the rod diameter of the fuel rods 1 in the outer region, and the distance between the fue...

Embodiment 3

[0042] The embodiment further defines or provides specific implementations on the basis of the supercritical water-cooled reactor provided in Example 1, as a technical solution for adjusting the local coolant flow in the inner and outer regions of the core assembly, so as to obtain the correct The inner fuel rods 2 or the outer fuel rods 1 in different regions have different cooling capacities, and the upper chamber 7 and the lower chamber 9 are both provided with throttles for guiding or restricting the flow of the coolant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com