Continuous vulcanizer for joint-free closed-loop steel rope core rubber conveying belt of belt feeder

A conveyor belt without joint technology, which is applied in the field of continuous vulcanizers for closed-loop steel cord rubber conveyor belts without joints for belt feeders, can solve the waste of structural materials, high power, and cannot be used to produce steel cord rubber conveyor belts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

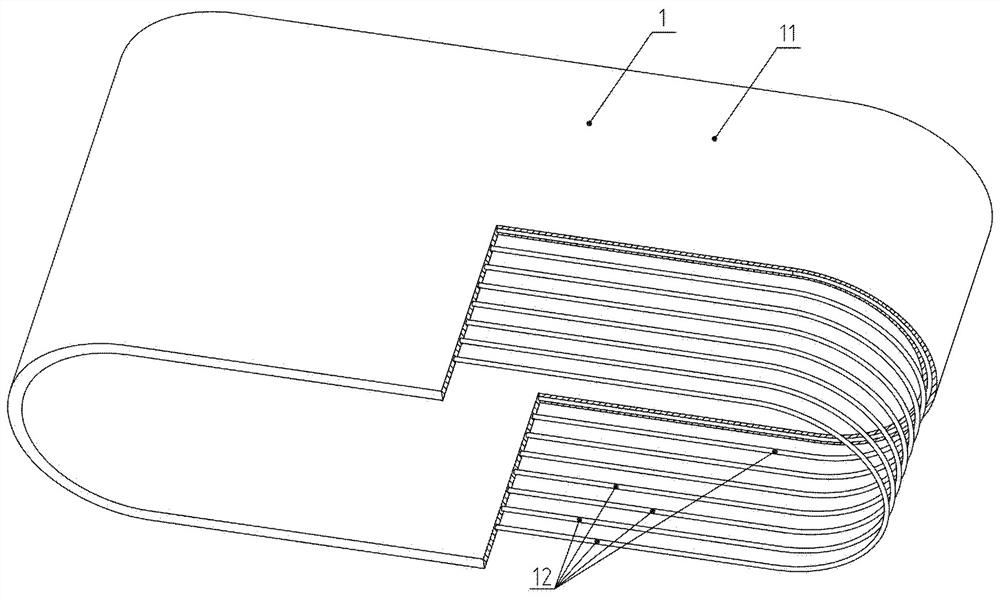

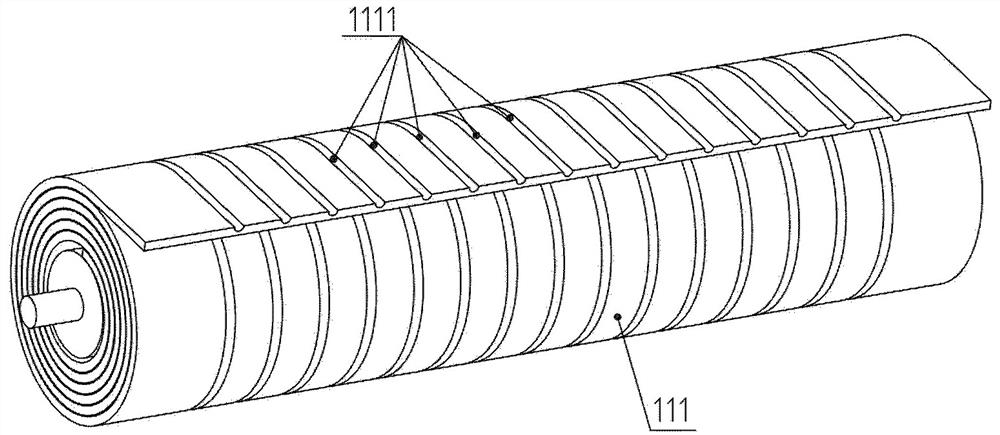

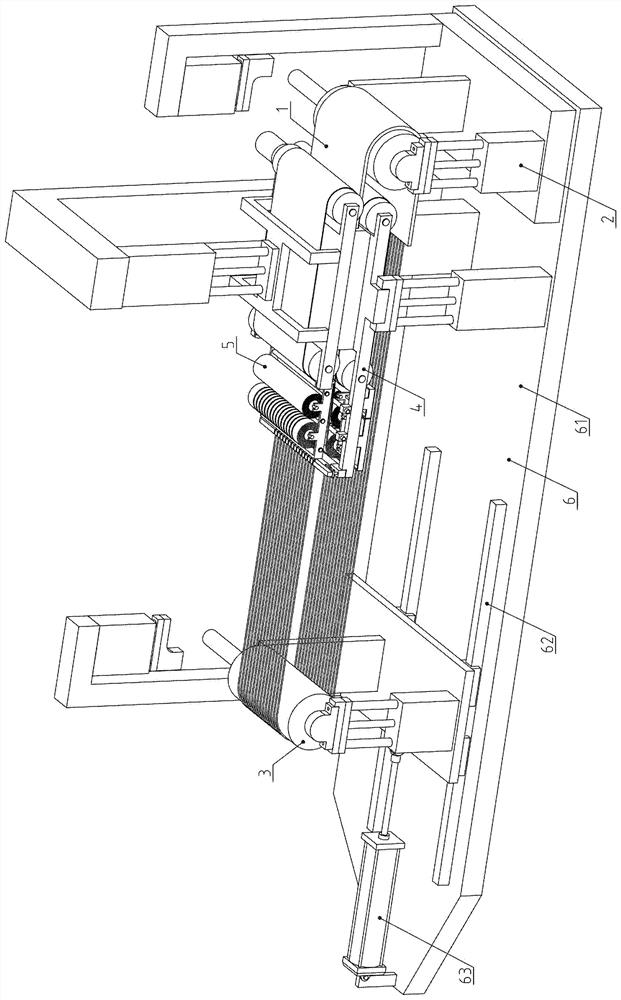

[0066]Example: SeeFigure 1 to 12.

[0067]A belt feeder without jointly looping steel rope core rubber conveyor belt continuous vulcanizer, including rack assembly 6; frame assembly 6 includes a rack 61, a linear guide 62 and a tensioning hydraulic cylinder 63, a linear guide 62 fixed The linear guide 62 is disposed in the frame 61; the tensioning hydraulic cylinder 63 includes a tensioning hydraulic cylinder body 631 and a tensioning hydraulic cylinder piston rod 632; tensioning the hydraulic cylinder body 631 fixes coupling on the rack 61 ;

[0068]Also included, conveying tape roller assembly 2, rear drum assembly 3, lower heating assembly 4, and upper heating assembly 5;

[0069]The conveying belt roller assembly 2 includes a conveyor tape drum 21, a front roller left bearing assembly 23, a front roller right bearing assembly 23, a front auxiliary mechanism hydraulic cylinder 24, a front roller lifting hydraulic cylinder 25, a front bearing seat 26 and a front auxiliary Power plate 27; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com