Heat-resistant communication transformer and fabrication method thereof

A manufacturing method and technology for transformers, which are applied in the directions of inductor/transformer/magnet manufacturing, transformer/inductor housing, transformer/inductor cooling, etc., can solve the problems of existing technologies such as no heat-resistant communication transformers, and achieve comprehensive mechanism performance. Excellent, small temperature effect, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

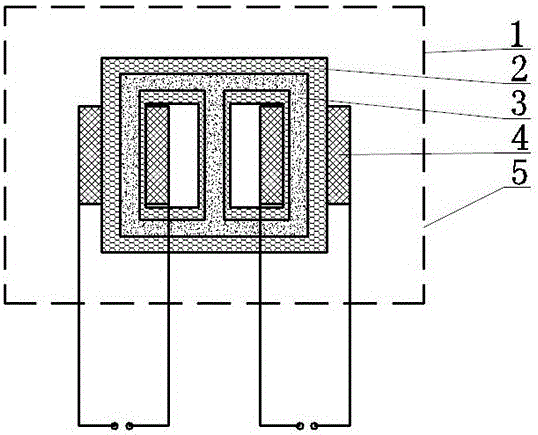

[0034] A heat-resistant communication transformer, including a skeleton, a winding 4, a magnetic core 3, a shielding cover 1, and a packaging material; a special molybdenum permal magnetic core 3 is applied, a ceramic skeleton 2 is applied, and an aluminum alloy shielding cover 1 is applied; Among them, the molybdenum Permal magnetic core 3 is sealed in the ceramic skeleton 2 by epoxy resin; the aluminum alloy shielding cover 1 covers the part of the whole transformer except the shielding cover 1, adopts a fully enclosed structure, and the aluminum alloy shielding cover 1 Ventilation slots 5 with a width of 1 mm are also provided every 5 mm.

[0035] The manufacturing method of the heat-resistant communication transformer comprises the following steps:

[0036] 1) Selection and preparation of various components

[0037] ① The skeleton is selected from the aluminum nitride-based ceramic skeleton 2 that matches the Japanese-shaped magnetic core 3, and the selection standard of ...

Embodiment 2

[0060] A heat-resistant communication transformer, including a skeleton, a winding 4, a magnetic core 3, a shielding cover 1, and a packaging material; a special molybdenum permal magnetic core 3 is applied, a ceramic skeleton 2 is applied, and an aluminum alloy shielding cover 1 is applied; Among them, the molybdenum Permal magnetic core 3 is sealed in the ceramic skeleton 2 by epoxy resin; the aluminum alloy shielding cover 1 covers the part of the entire transformer except the shielding cover 1, and adopts a fully enclosed structure. Ventilation slots 5 with a width of 2 mm are also provided every 5 mm.

[0061] The manufacturing method of the heat-resistant communication transformer comprises the following steps:

[0062] 1) Selection and preparation of various components

[0063] ① The skeleton is selected from the aluminum nitride-based ceramic skeleton 2 that matches the Japanese-shaped magnetic core 3, and the selection standard of the aluminum nitride-based ceramic i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com