Flip chip interconnection process method for high frequency chip waveguide package

A process method and chip technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effect of reducing package size, small bonding size, and good controllability of coherent parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

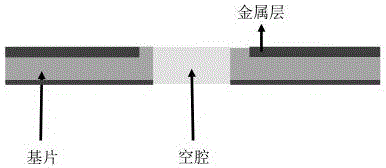

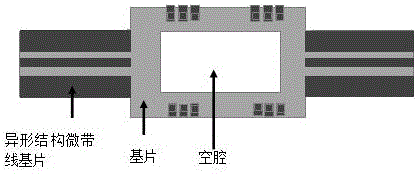

[0051] Such as Figure 1-7 As shown, when a special-shaped microstrip line substrate is used, the specific package flip-chip interconnection process steps are as follows:

[0052] First, according to the size of the chip and its pad, and the performance design parameters of the corresponding functional modules, the size, cavity and irregular boundary structure of the special-shaped microstrip line substrate are designed and manufactured;

[0053] Then, use solder to flatly mount the microstrip line substrate on the surface of the package cavity;

[0054] Then according to the size of the chip pad, make flip-chip solder bumps on the chip pad;

[0055] Finally, flip-chip bonding technology is used to realize the interconnection between the chip and the microstrip line substrate.

[0056] In the steps of this interconnection process, based on the structural design of the special-shaped microstrip line substrate, the microstrip line structure is fabricated on the quartz substrat...

Embodiment 2

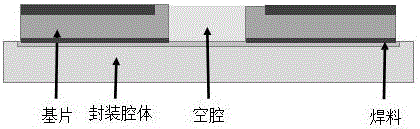

[0064] Such as Figure 8-14 As shown, when flip-chip interconnection is used, the specific package flip-chip interconnection process steps are as follows:

[0065] 1. According to the packaging design requirements, select the appropriate material to make the supporting substrate of the chip and the microstrip line substrate;

[0066] 2. According to the size of the chip and the microstrip line substrate, make a groove on the substrate for placing the chip and the microstrip line substrate, the purpose is to fix the position of the chip and the microstrip line substrate during flip-chip welding, and at the same time Ensure the flatness of the patch;

[0067] 3. Mount the chips and microstrip line substrates flatly in the substrate grooves to ensure the high flatness requirements of the flip-chip welding technology for the samples;

[0068] 4. According to the size and spacing of chip pads, the size and spacing of microstrip line substrate pads, and the corresponding functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com