High-efficiency lithium-sulfur battery additive and application method thereof

A lithium-sulfur battery, electrolyte additive technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of lithium-sulfur battery capacity attenuation, reduce volume expansion, improve specific surface area and active material utilization, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: the weight ratio of carbon composite material and electrolyte additive is 1:10; Carbon composite material is made up of following raw materials by weight: 60 parts of carbon material, 3 parts of acetylene black, SnO 5 parts of coated glass sheet, phenyl ring 1 part of hexane; The electrolyte additive is composed of the following raw materials in parts by weight: 1 part of lignosulfonate, 2 parts of humic acid, 5 parts of silicic acid, 2 parts of 2-vinylpyridine, ethoxylated pentafluorocyclic 2 parts of phosphazene, 3 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate, 1 part of mesoporous silicate.

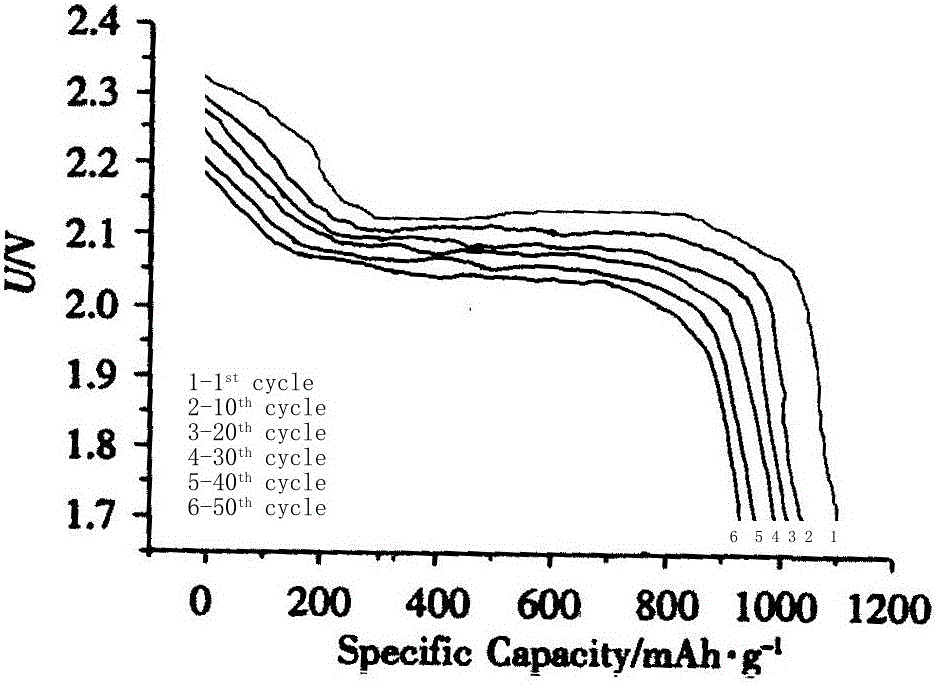

[0020] Such as figure 1 As shown, the specific capacity of the present invention decreases less after being charged for many times, and the service life is longer and the service life is longer.

Embodiment 2

[0021] Embodiment two: the weight ratio of carbon composite material and electrolyte additive is 1:12; Carbon composite material is made up of following raw materials in parts by weight: 70 parts of carbon material, 5 parts of acetylene black, SnO 2 parts of coated glass sheet, phenyl ring 2 parts of hexane; The electrolyte additive consists of the following raw materials in parts by weight: 2 parts of lignosulfonate, 3 parts of humic acid, 2 parts of silicic acid, 3 parts of 2-vinylpyridine, ethoxy pentafluorocyclo 5 parts of phosphazene, 1 part of 1-ethyl-3-methylimidazolium tetrafluoroborate, 2 parts of mesoporous silicate.

Embodiment 3

[0022] Embodiment 3: The weight ratio of carbon composite material and electrolyte additive is 1:15 The carbon composite material is made up of following raw materials in parts by weight: 80 parts of carbon material, 2 parts of acetylene black, SnO2 coated glass sheet 3 parts, phenylcyclohexane 3 parts of alkane; The electrolyte additive is composed of the following raw materials in parts by weight: 3 parts of lignosulfonate, 1 part of humic acid, 3 parts of silicic acid, 4 parts of 2-vinylpyridine, ethoxy pentafluorocyclic phosphorus 1 part of nitrile, 2 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate, 3 parts of mesoporous silicate.

[0023] A method for using an additive for a high-efficiency lithium-sulfur battery, including a method for using a carbon composite material and an additive for an electrolyte solution. The method for using the carbon composite material is as follows: carbon materials, acetylene black, and SnO2 coated glass flakes are ball milled and pulv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com