LED lamp power supply capable of reducing power at regular time

An LED lamp and power reduction technology, which is applied in the field of timed power reduction LED lamp power supply, can solve the problems of increasing production cost, increasing energy loss, increasing environmental pollution, etc., to facilitate installation and disassembly, reduce energy loss, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

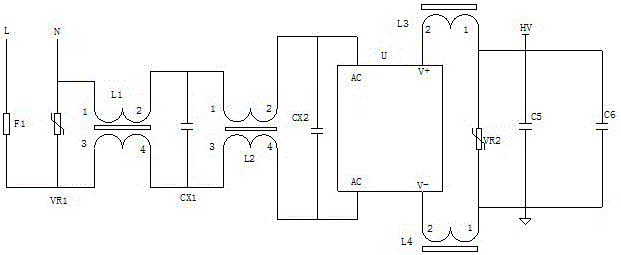

[0027]Specific implementation method: when the main body of the circuit is energized and running, the short circuit protection mechanism works, the live wire L transmits the current to the fuse F1, and then the fuse F1 transmits the current to the rectifier transformer L1, and then the rectifier transformer L1 transmits the current to the rectifier transformer L2 and Capacitor CX1, then the rectifier transformer L2 sends the current to the rectifier U, and then the rectifier U sends the current to the main body of the circuit. When the main body of the circuit is short-circuited, the rectifier U receives the short-circuit signal and sends out an instruction, the capacitor CX1 and the capacitor CX2 are disconnected, and the fuse F1 stop working, the design realizes the short circuit protection of the main body of the circuit.

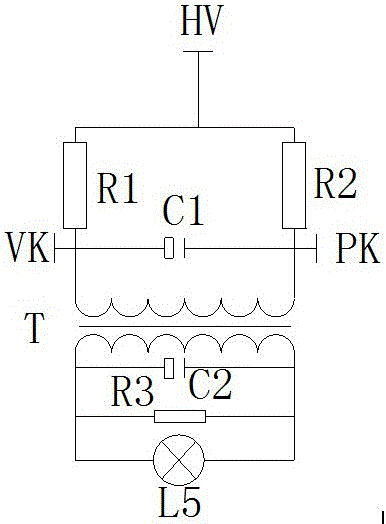

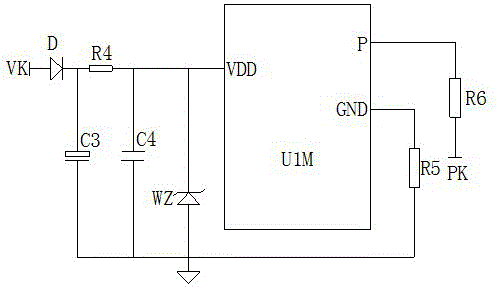

[0028] When the LED lamp L5 works for four hours, the PWM regulator U1M works and sends an instruction, the value of the resistor R6 becomes larger, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com