Crumb of block copolymer and adhesive composition

A technology of block copolymers and polymers, applied in the direction of film/sheet-like adhesives, adhesives, bonding methods, etc. The effect of excellent performance and low odor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

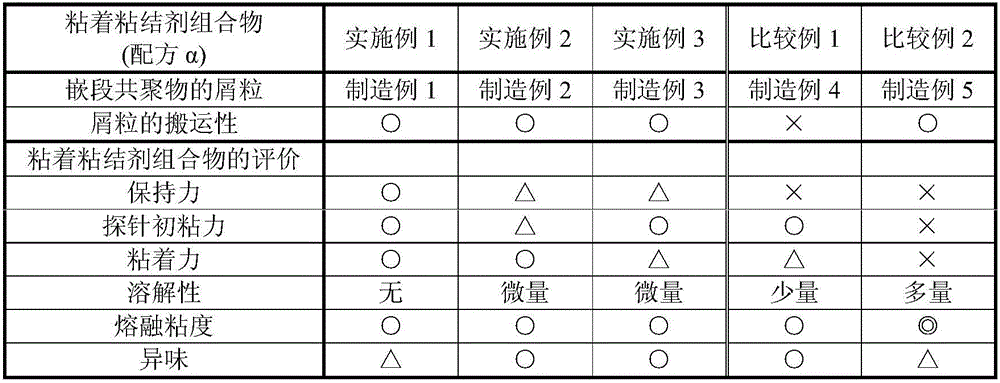

Examples

Embodiment

[0339] The present embodiment will be described in detail below with specific examples and comparative examples, but the present embodiment is not limited to the following examples. In addition, in the following examples and comparative examples, the measurement of the characteristic and physical property of a polymer was performed by the following method.

[0340] [(1): Characteristics of block copolymer crumbs]

[0341]

[0342] Regarding the weight-average molecular weight of block copolymer crumbs, use a calibration curve (prepared using the peak molecular weight of standard polystyrene) obtained from the measurement of commercially available standard polystyrene, and obtain the block based on the peak molecular weight of the chromatogram. The weight average molecular weight of the copolymer crumb. When the block copolymer is a block copolymer composition composed of two different structures of the component (A) and the component (B), the peak with the smallest weight a...

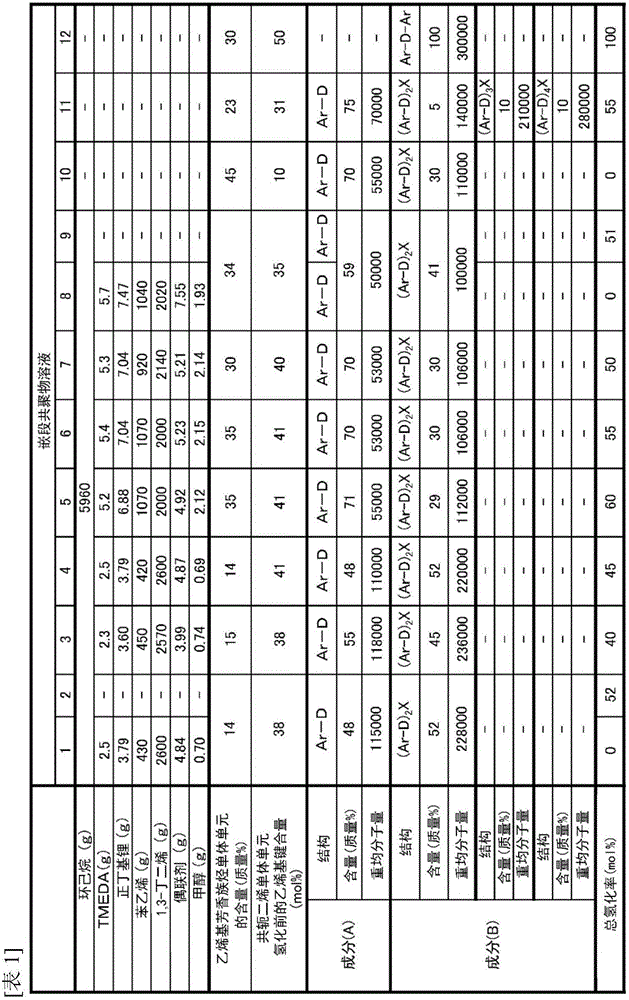

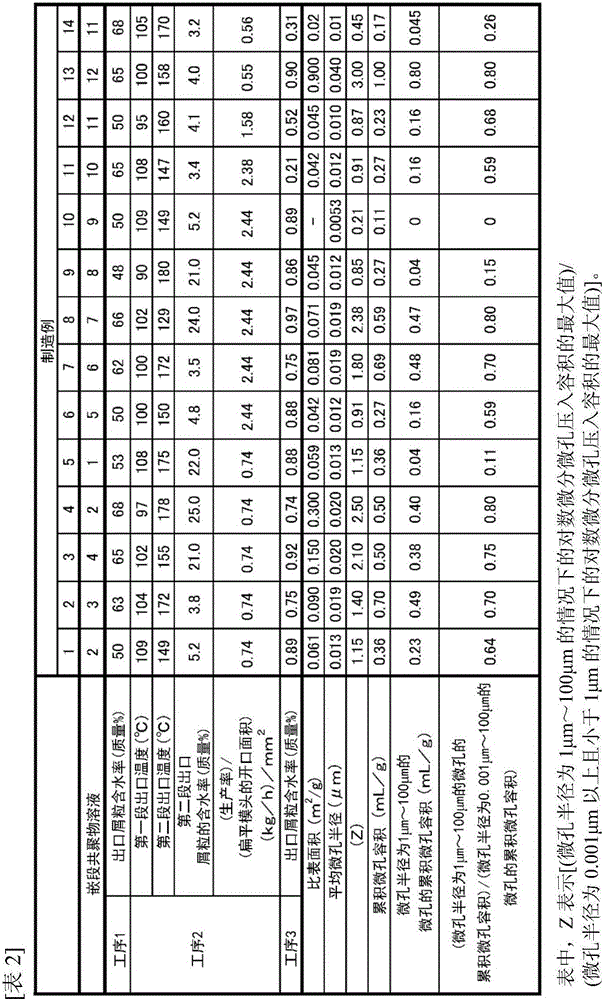

manufacture example 1

[0486] 0.3 parts by mass of octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate was added to the block copolymer solution 2 with respect to 100 parts by mass of the above-mentioned block copolymer , for thorough mixing. The hydrogenated block copolymer solution was stripped at 95°C for 1 hour. In the stripping, Na salt of a styrene-maleic anhydride copolymer was added as a crumb reducing agent.

[0487] The aqueous slurry containing hydrogenated block copolymer composition crumbs in the obtained aqueous slurry was sent to a vibrating sieve with a mesh of 1 mm for dehydration treatment (), and then the history was measured by the above-mentioned method. The water content of the hydrogenated block copolymer crumbs in was shown. The water content at this time was 50% by mass.

[0488] The hydrogenated block copolymer crumbs were dehydrated and dried using separate devices.

[0489] First, it was supplied to a single-screw extruder type water squeezer, and extruded at a...

manufacture example 2~9

[0494] In addition to changing the block copolymer solution used as shown in Table 2, the moisture content of the crumbs at the outlet of , the outlet temperature of the first stage of , and the outlet temperature of the second stage of Block copolymer crumbs were obtained in the same manner as in Production Example 1 except for the moisture content of the crumbs. The crumbs of the block copolymer were measured by the same method as in Production Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com