A boron-doped composite for lithium-sulfur battery, a process for preparing said composite, an electrode material and a lithium-sulfur battery comprising said composite

A lithium-sulfur battery and composite technology, applied in the field of lithium-sulfur battery composites, can solve problems such as unsatisfactory cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

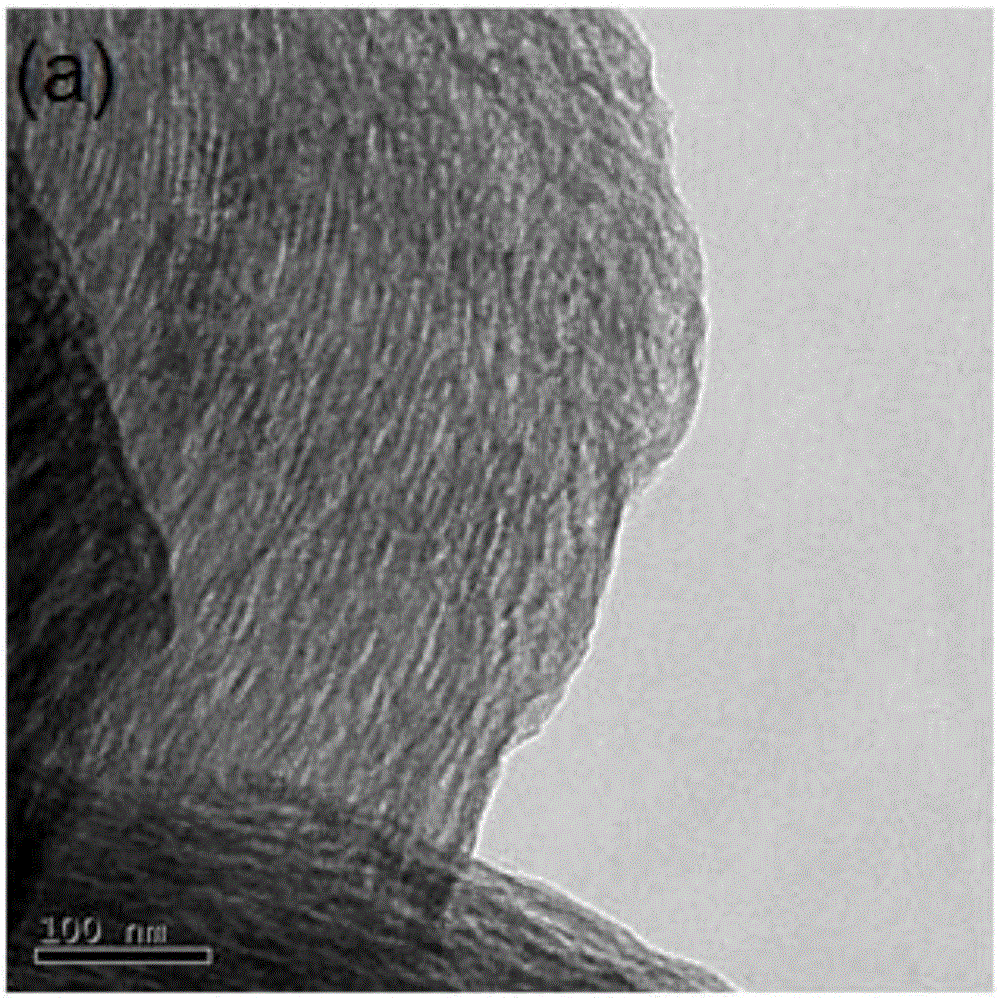

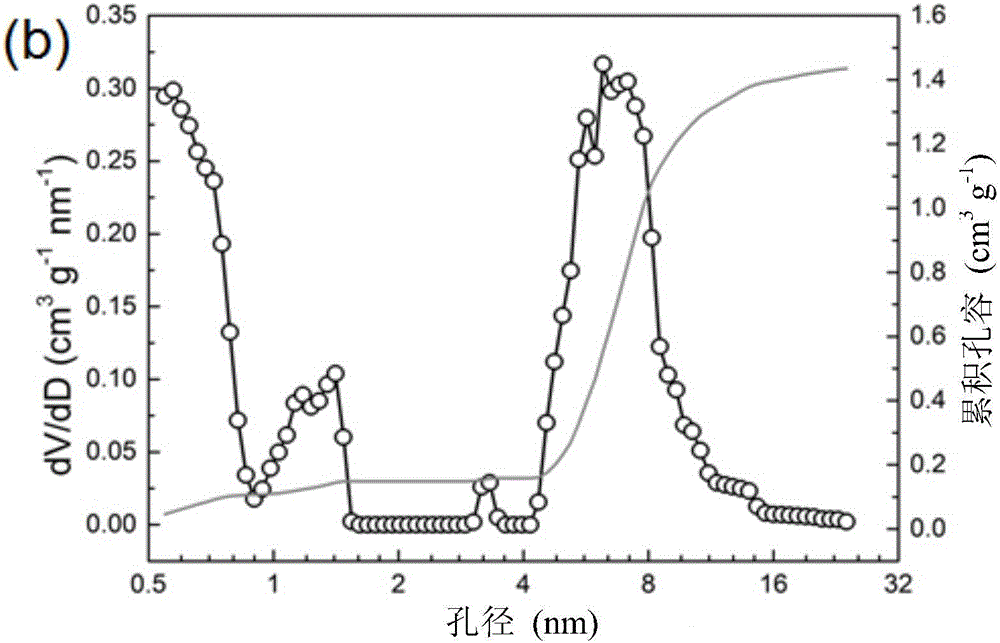

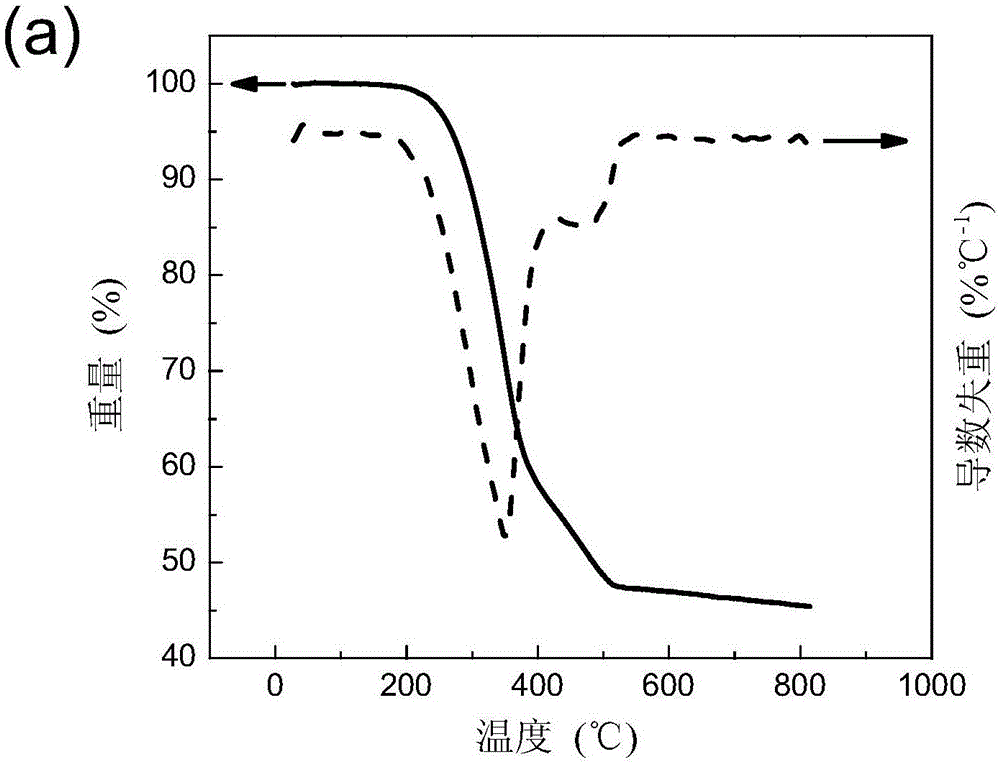

[0089] Embodiment 1: Preparation of S / BPC

[0090] 1) Provide boron-doped carbon substrates:

[0091] a) Provide template SBA-15 as reported by Zhao:

[0092] SBA-15 was prepared by the procedure described previously. First, 4 g of Pluronic P123 (EO 20 PO 70 EO 20 ) was dissolved in 120mL of hydrochloric acid (2M). Then 9 mL of tetraethylorthosilicate was added to the solution. The mixture was vigorously stirred at 38°C for 8 minutes, allowed to stand for 24 hours, and then hydrothermally treated in an autoclave at 100°C for a further 24 hours. The white product was filtered, washed, dried, and finally calcined in air at 550°C for 4 hours to obtain SBA-15 without surfactant.

[0093] b) Preparation of BPCs:

[0094] First, 1 gram of boric acid was dissolved in 5 mL of water under the action of ultrasonic waves, and heated at 70 °C for 1 hour. Then add 1 gram of fructose, 0.14 gram of concentrated H 2 SO 4 and 1.0 g of SBA-15 were successively added to the above solu...

Embodiment 2

[0107] Embodiment 2: preparation S / CMK-3

[0108] 1) Provide undoped carbon substrate:

[0109] a) Preparation of SBA-15:

[0110] Repeat the operation of step a) in Example 1.

[0111] b) Preparation of CMK-3:

[0112] As in Example 1, CMK-3 was also prepared using the nanocasting method. Dissolve 1.25 g fructose in 5.0 mL containing 0.14 g concentrated H 2 SO 4 of water. Then 1.0 g of SBA-15 was dispersed in the solution, and sonication was performed for 1 hour. The mixture was heated at 100°C for 12 hours and at 160°C for a further 12 hours, then another 5 mL containing 0.8 g fructose and 0.09 g H 2 SO 4 The aqueous solution repeats the injection process once.

[0113] c) Annealing:

[0114] The obtained dark brown intermediate product was completely carbonized at 900 °C in Ar flow for 5 h.

[0115] d) remove the template:

[0116] To remove the SBA-15 template, the carbonized product was stirred in 10 wt% HF solution for 4 hours. The prepared CMK-3 was collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com