Device system applicable to flue gas and powder material mixed reaction

A powder and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of aggravated powder agglomeration, accelerated wear, poor sealing effect, etc., to ensure the quality of storage materials and transportation effect, good crushing and loosening effect, effect of ensuring bridge breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

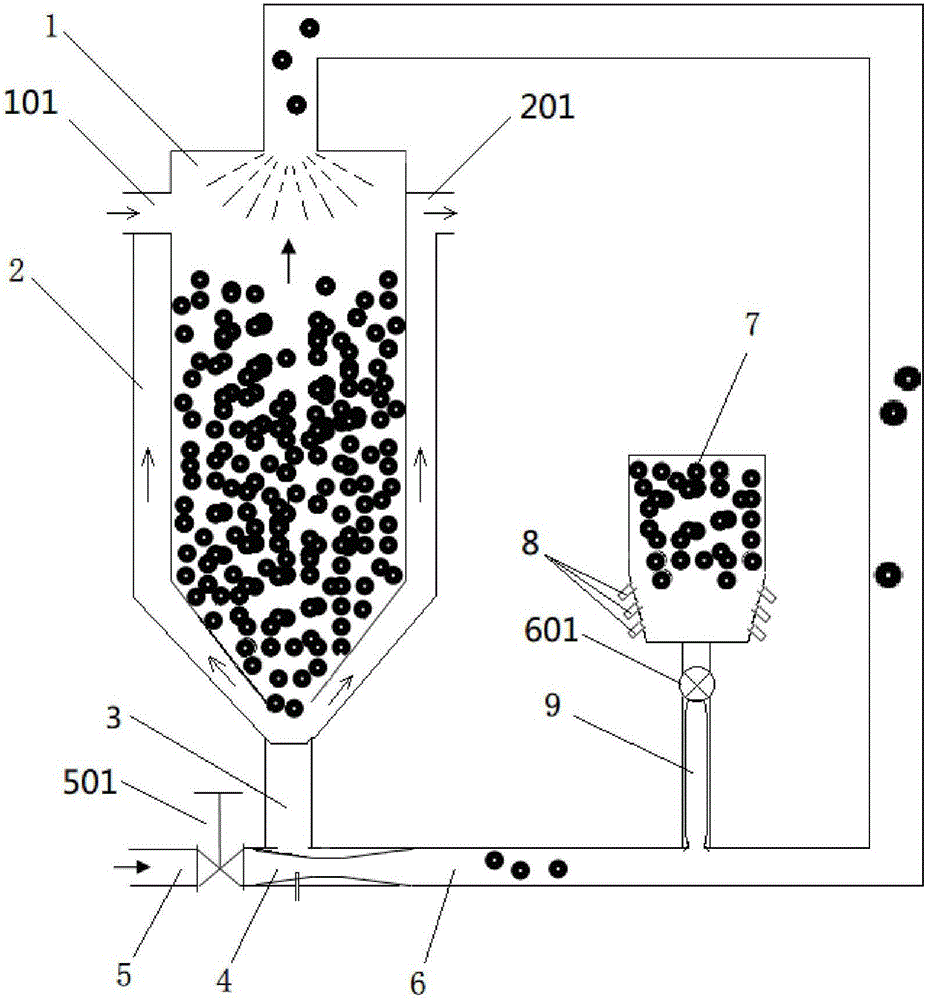

[0035] refer to figure 1, a device system suitable for the mixed reaction of flue gas and powder, comprising a reactor 1 with a vertical cylindrical structure, the top of which is provided with a powder inlet, the bottom is provided with a powder outlet, the outer wall is provided with a jacket, and the jacket A certain distance is formed between the inner wall of the reactor and the outer wall of the reactor 1 to form an air flow chamber 2 for the circulation of flue gas. The inner cavity of the reactor communicates with the air flow chamber 2 through the bottom opening, and the upper part of the side wall of the reactor is provided with a flue gas inlet 101. , The upper part of the side wall of the jacket is provided with a flue gas outlet 201 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com