Gantry type laser engraving machine

A laser and radium engraving technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as inconsistent environmental protection concepts, natural environmental pollution, and lack of randomness, so as to improve product stability and simple process , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, a detailed description will be provided in conjunction with the preferred implementation side and accompanying drawings, as follows:

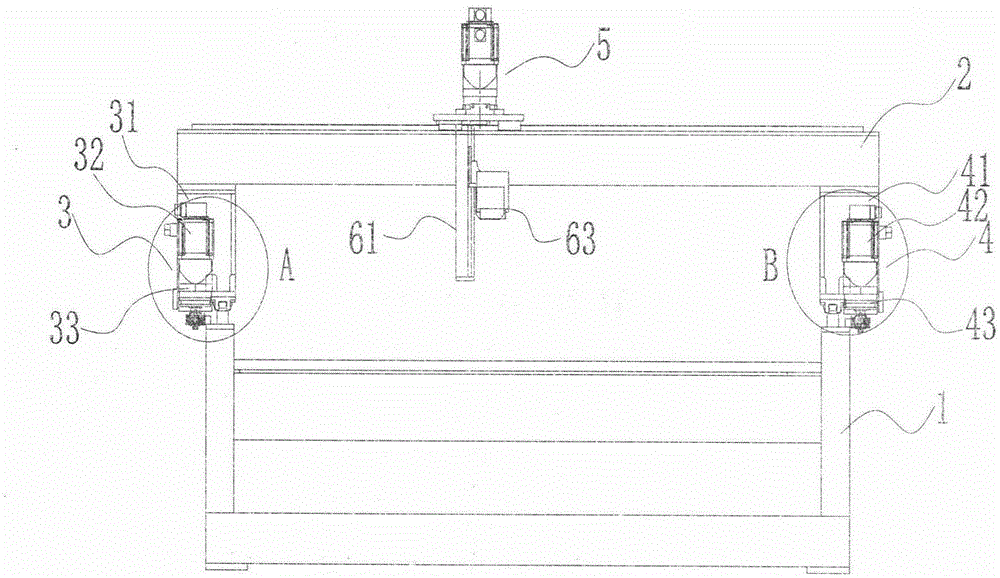

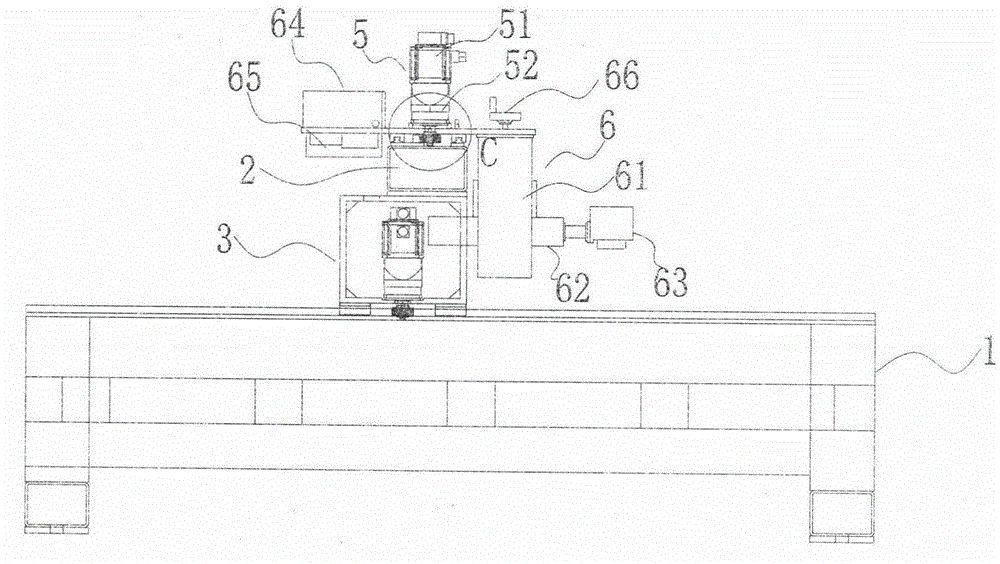

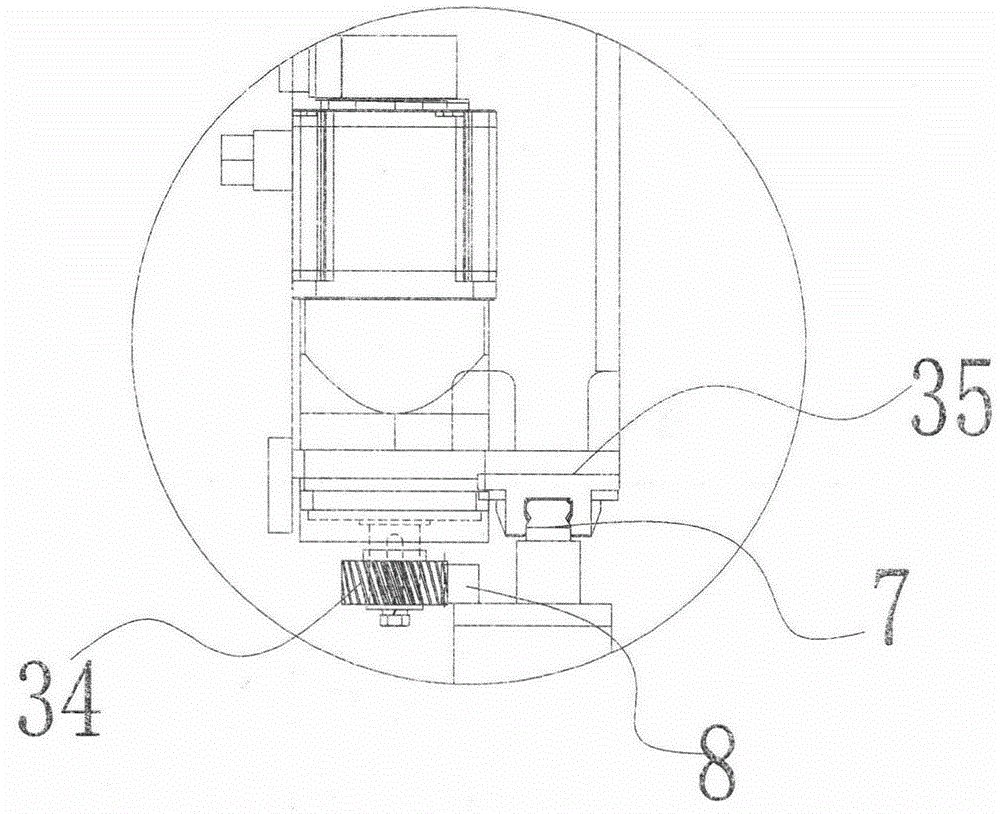

[0021] Such as Figure 1 to Figure 5 As shown, a gantry laser engraving machine includes a gantry body 1, two X-axis guide rail mechanisms are arranged on the gantry body 1, and a beam 2 perpendicular to the X-axis guide rail mechanism is arranged on the top of the gantry body 1. The two ends of the beam 2 are respectively connected to the X-axis guide rail mechanism through the X1-axis servo system 3 and the X2-axis servo system 4 and slide on the X-axis guide rail mechanism. The beam 2 is provided with a Y-axis guide rail mechanism extending toward its length. A Y-axis servo system 5 is provided on the axis guide rail mechanism, and a laser engraving mechanism 6 is connected to one side of the Y-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com