Super-macroporous three-dimensional cubic channel spherical composite carrier and supported polyethylene catalyst, and preparation methods and applications thereof

A three-dimensional cubic and composite carrier technology, applied in the preparation method and field of composite carrier, can solve the problems of poor thermal stability and hydrothermal stability, low ethylene polymerization activity, affecting catalytic activity, etc., and achieve stable mesoporous structure and high catalytic performance The effect of high activity and load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a second aspect, the present invention provides a method for preparing a spherical composite carrier with super-large three-dimensional cubic channels, characterized in that the method comprises the following steps:

[0036] Preparation of silica filter cake: the template agent and the silicon source are mixed and reacted in an acidic aqueous solution, and then the materials obtained after the mixed reaction are filtered and washed in turn;

[0037] Preparation of silica gel: in the presence of an inorganic acid solution, the contact reaction of water glass and n-butanol is carried out, and then the pH value of the solution obtained after the reaction is adjusted to 2-4;

[0038] Preparation of carrier: the prepared silica filter cake and the silica gel are mixed and then ball-milled, spray-dried and calcined in sequence,

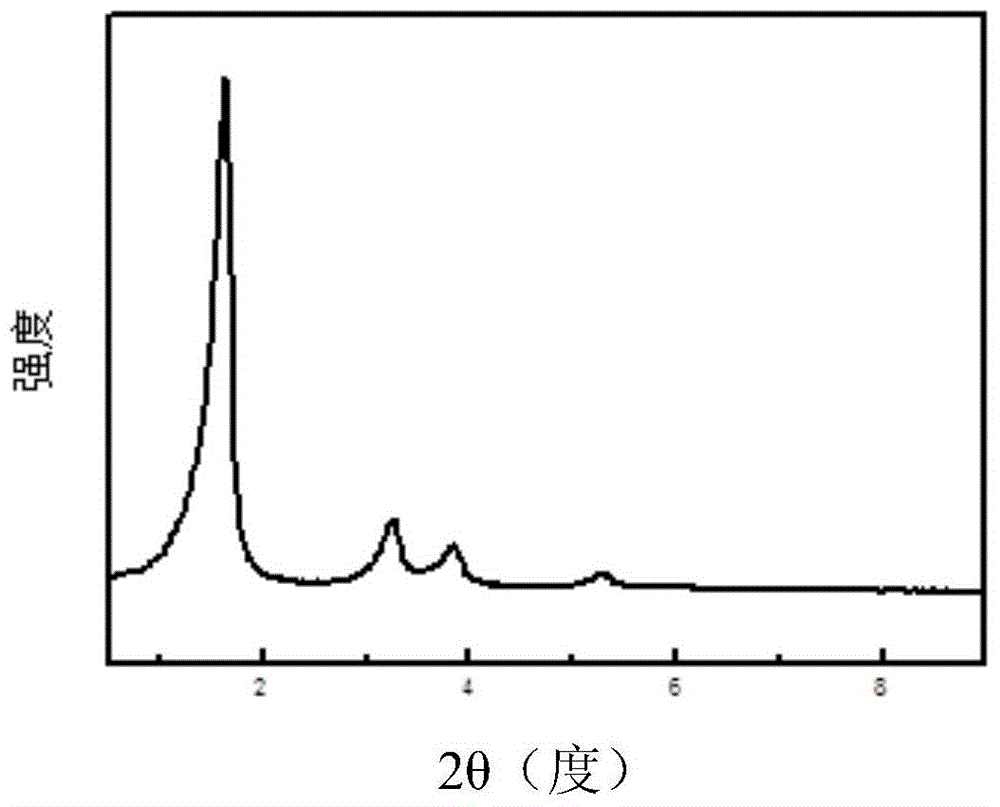

[0039] Wherein, the method makes the prepared carrier have an average particle diameter of 20-60 μm and a specific surface area of 200-600 m 2...

Embodiment 1

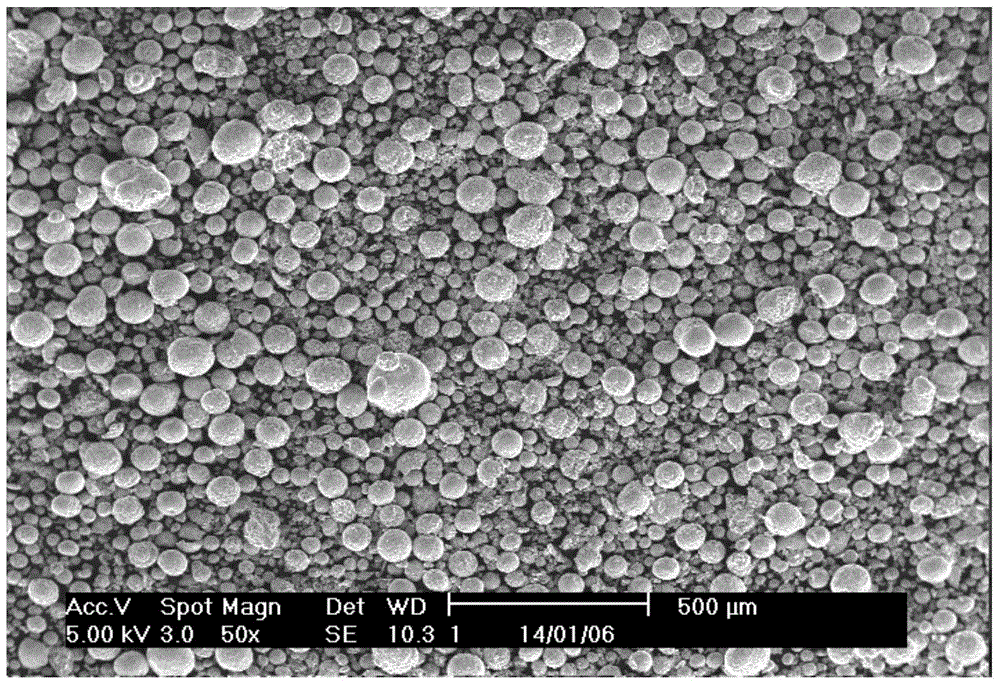

[0088] This example is used to illustrate the super-porous three-dimensional cubic channel spherical composite carrier, the supported polyethylene catalyst and the preparation method thereof according to the present invention.

[0089] (1) Preparation of carrier

[0090] Dissolve 6g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene P123 in 10mL of concentrated hydrochloric acid and 220mL of deionized aqueous solution, stir at 15°C for 4h to form a transparent solution, and then add 6g to this transparent solution. Ethanol and stirred for 1 h, then the solution was placed in an environment of 30 °C, 12.9 g of ethyl orthosilicate was added to it, the temperature was kept at 30 °C, and the pH value was 3. The conditions were stirred for 24 h, and then the solution was transferred to In the reaction kettle lined with polytetrafluoroethylene, the silica filter cake was obtained by filtration and washing after being crystallized in a 100 ℃ oven for 24 hours.

...

Embodiment 2

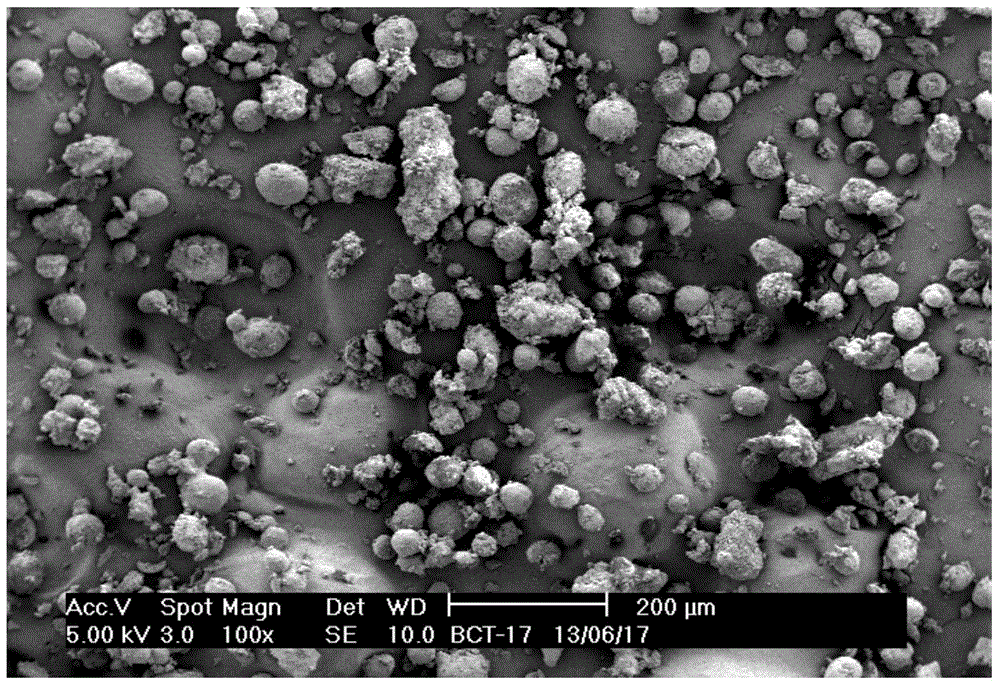

[0110]This example is used to illustrate the super-porous three-dimensional cubic channel spherical composite carrier, the supported polyethylene catalyst and the preparation method thereof according to the present invention.

[0111] (1) Preparation of carrier

[0112] Dissolve 6 g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene P123 in 10 mL of concentrated hydrochloric acid and 220 mL of deionized aqueous solution, stir at 20 °C for 6 h to form a transparent solution, and then add 5.6 g ethanol and stirred for 1 h, then the solution was placed in an environment of 35 ° C, 12.9 g of ethyl orthosilicate was added to it, the temperature was kept at 35 ° C and the pH value was 4, and stirred for 24 h, and then the solution was transferred The silica filter cake was obtained by filtration and washing after being crystallized in an oven at 90°C for 24 hours in a polytetrafluoroethylene-lined reaction kettle.

[0113] The water glass with a concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com