Ethylene polymerization method and polyethylene

An ethylene polymerization and polymerization reaction technology, applied in the field of polyethylene, can solve the problems of pore wall collapse, poor thermal stability and hydrothermal stability, low ethylene polymerization activity, etc., and achieves unbreakable, stable mesoporous structure, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

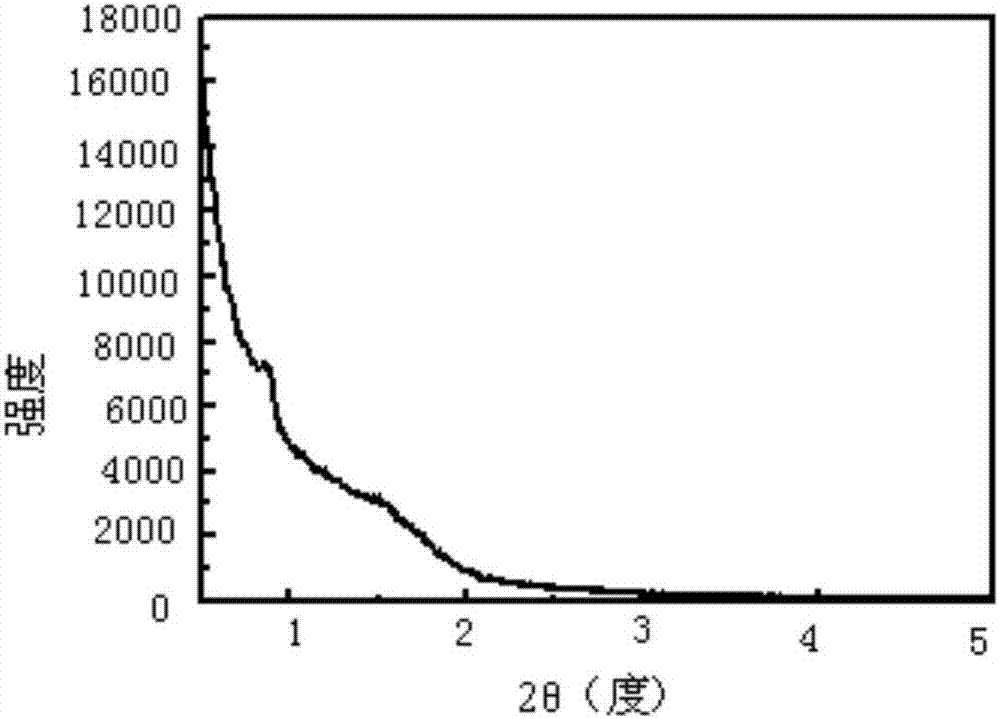

[0025] The preparation method of the spherical composite material is not particularly limited in the present invention, as long as it contains a mesoporous molecular sieve material with a three-dimensional cubic cage structure and silica gel and has the above-mentioned microscopic size. In order to further improve the performance of polyethylene products, Preferably, the preparation method of the spherical composite material comprises the following steps:

[0026] (1) providing a mesoporous molecular sieve material with a three-dimensional cubic cage structure or preparing a filter cake of a mesoporous molecular sieve material with a three-dimensional cubic cage structure as component a;

[0027] (2) providing silica gel or preparing a filter cake of silica gel as component b;

[0028] (3) The component a, the component b and the binder are mixed and ball milled, and the solid powder obtained after ball milling is made into a slurry with water, and then the obtained slurry is ...

Embodiment 1

[0080] This example is used to illustrate the ethylene polymerization method and the obtained polyethylene of the present invention.

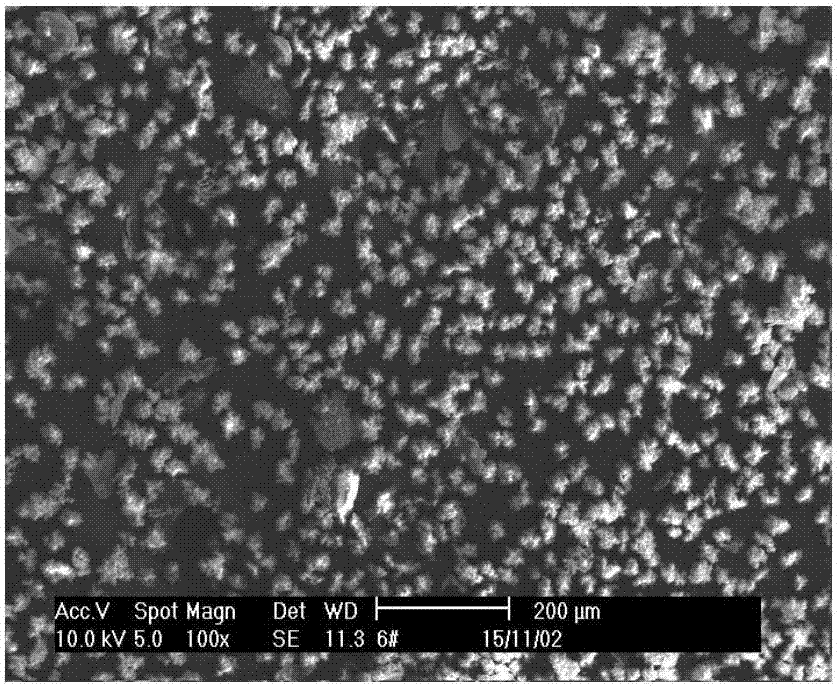

[0081] (1) Preparation of spherical composite materials

[0082] 1.46g (0.0001mol) template agent F108, 5.24g (0.03mol) K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 at 38°C until F108 is completely dissolved;

[0083] Add 4.2g (0.02mol) tetraethyl orthosilicate to the above solution, stir at 38°C for 15 minutes, and stand at 38°C for 24 hours;

[0084] Then it was transferred to an agate-lined reaction kettle, crystallized at 100°C for 24 hours, then filtered and washed with deionized water for 4 times, and then suction filtered to obtain a filter material of mesoporous molecular sieve material with a three-dimensional cubic cage structure. Pie A1.

[0085] The water glass with a concentration of 15% by weight and the sulfuric acid solution and glycerin with a concentration of 12% by weight are mixed in a weigh...

Embodiment 2

[0111] This example is used to illustrate the ethylene polymerization method and the obtained polyethylene of the present invention.

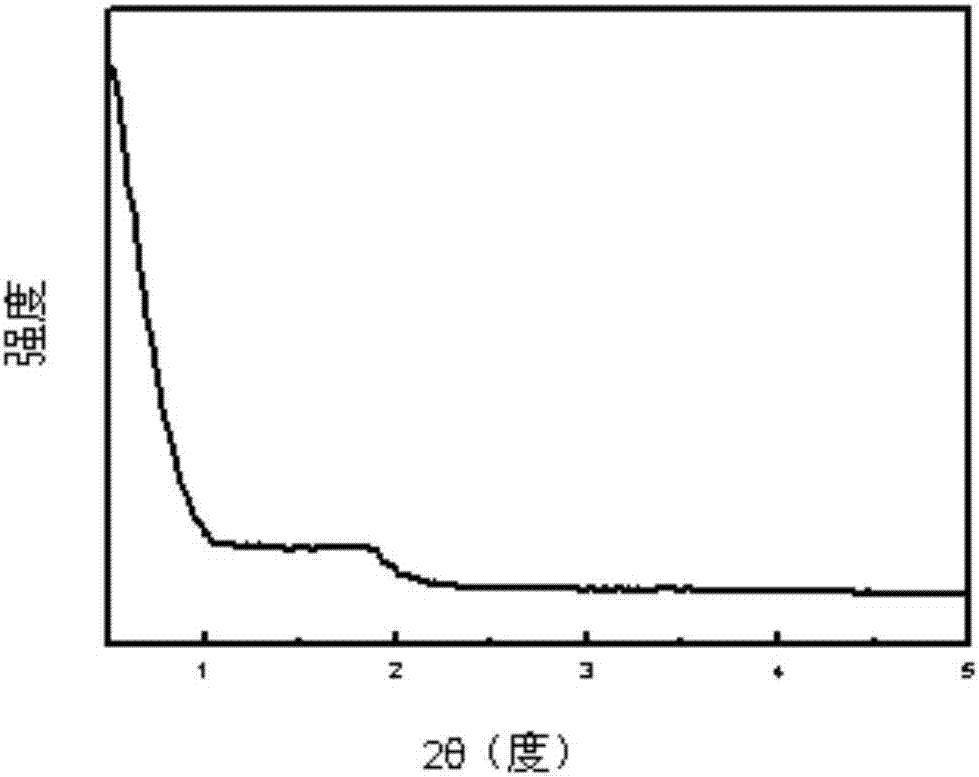

[0112](1) Preparation of spherical composite materials

[0113] 1.46g (0.0001mol) template agent F108, 6.96g (0.04mol) K 2 SO 4 Stir with 60g of hydrochloric acid solution with a normality of 2 at 38°C until F108 is completely dissolved;

[0114] Add 3.1g (0.015mol) ethyl orthosilicate to the above solution, stir at 45°C for 15min, and stand at 45°C for 30h;

[0115] It was then transferred to an agate-lined reactor, crystallized at 120°C for 30 h, then filtered and washed 4 times with deionized water, and then suction filtered to obtain a filter cake of mesoporous molecular sieve materials with a three-dimensional cubic cage structure A2.

[0116] Water glass with a concentration of 20% by weight and a sulfuric acid solution with a concentration of 12% by weight and propylene glycol were mixed in a weight ratio of 4:1:1 and contacted for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com